Pulling reinforcement method for internal fissure of dangerous rock

A technology for fissures and dangerous rocks, applied in the field of tie reinforcement of internal fissures in dangerous rocks, can solve the problems of inconvenient handling and construction, excessive length of anchor rods, and economic waste, saving manpower and material resources, saving steel and material costs, Ease of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

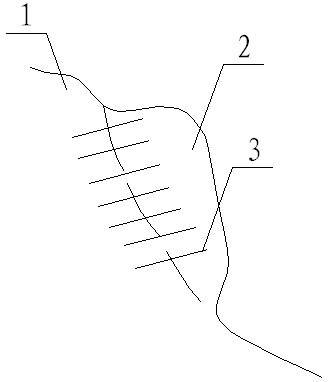

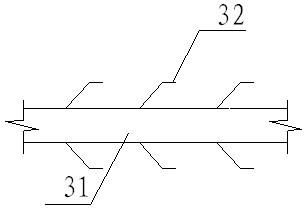

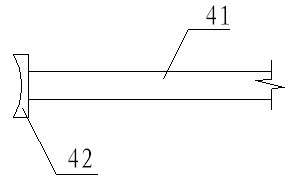

[0027] Embodiment 1: see figure 1 , figure 2 and image 3 , a method for tightening internal cracks in dangerous rocks, comprising the following steps:

[0028] 1) Stability analysis of the dangerous rock mass 2: According to the mechanical parameters of the dangerous rock mass and internal cracks provided by the geological survey report, including the gravity and geometric shape of the dangerous rock mass, the sliding force of the dangerous rock mass and the relationship between the dangerous rock mass and the parent The frictional resistance between rock masses, etc., according to the stability coefficient requirements of the reinforcement and treatment of dangerous rock masses, the anchoring force required for the reinforcement of dangerous rock masses is calculated, and the cross-sectional area of the anchor rod and the anchoring force are calculated according to the anchoring force. quantity. The stability factor requirements are determined according to the relevant...

Embodiment 2

[0036] Example 2, in the actual construction process, in the treatment of group collapse dangerous rocks, the above-mentioned method is used to carry out the bolt tie construction step by step from the internal cracks closest to the stable parent rock mass, and finally construct the closest to the outer surface. For internal cracks, tie knots one by one until the overall reinforcement is completed. The invention can achieve a very good treatment effect on the treatment of mass collapse dangerous rocks. see Figure 4 , in the construction process, adopt the construction method described in embodiment 1, when drilling the anchor hole, drill from the appearance of the second dangerous rock mass 22 and the fourth dangerous rock mass 24 (ie the outermost dangerous rock mass), and make Anchor holes pass through multi-level internal fissures, and then are constructed step by step from the internal fissures closest to the stable parent rock mass 1. First, the parent rock mass 1 is co...

Embodiment 3

[0037] Embodiment 3, the present invention is applied to rock mass underground excavation engineering, see Figure 5 During construction, the dangerous rock mass 2 in the surrounding rock is bound and reinforced by the anchor rod 3 and the parent rock mass 1, which can effectively prevent the dangerous rock block from falling or collapsing in the surrounding rock, and ensure the safety of construction and use.

[0038] In addition, the anchor rod structure adopted in the present invention can also be replaced by anchor pieces of other structural forms such as anchor cables.

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com