Unit-form residential building system of totally assembled type prefabricated concrete structure

A technology of prefabricated concrete and residences, which is applied in the construction of residences, building structures, buildings, etc. It can solve the problems of complex on-site construction procedures and management, failure to meet the requirements of sustainable development, and difficulty in ensuring construction quality, so as to achieve easy construction quality Guarantee, reduce construction cost and facilitate construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

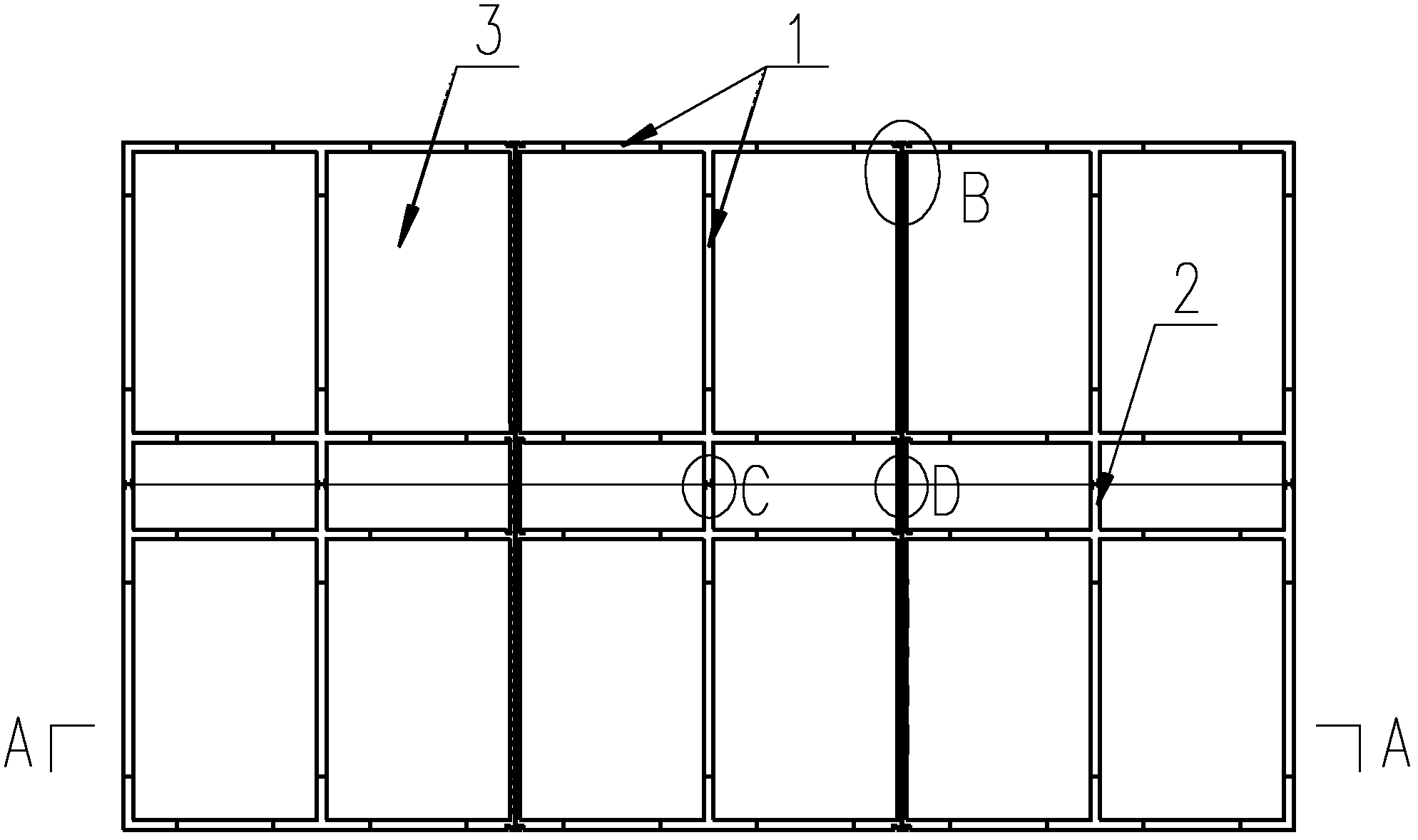

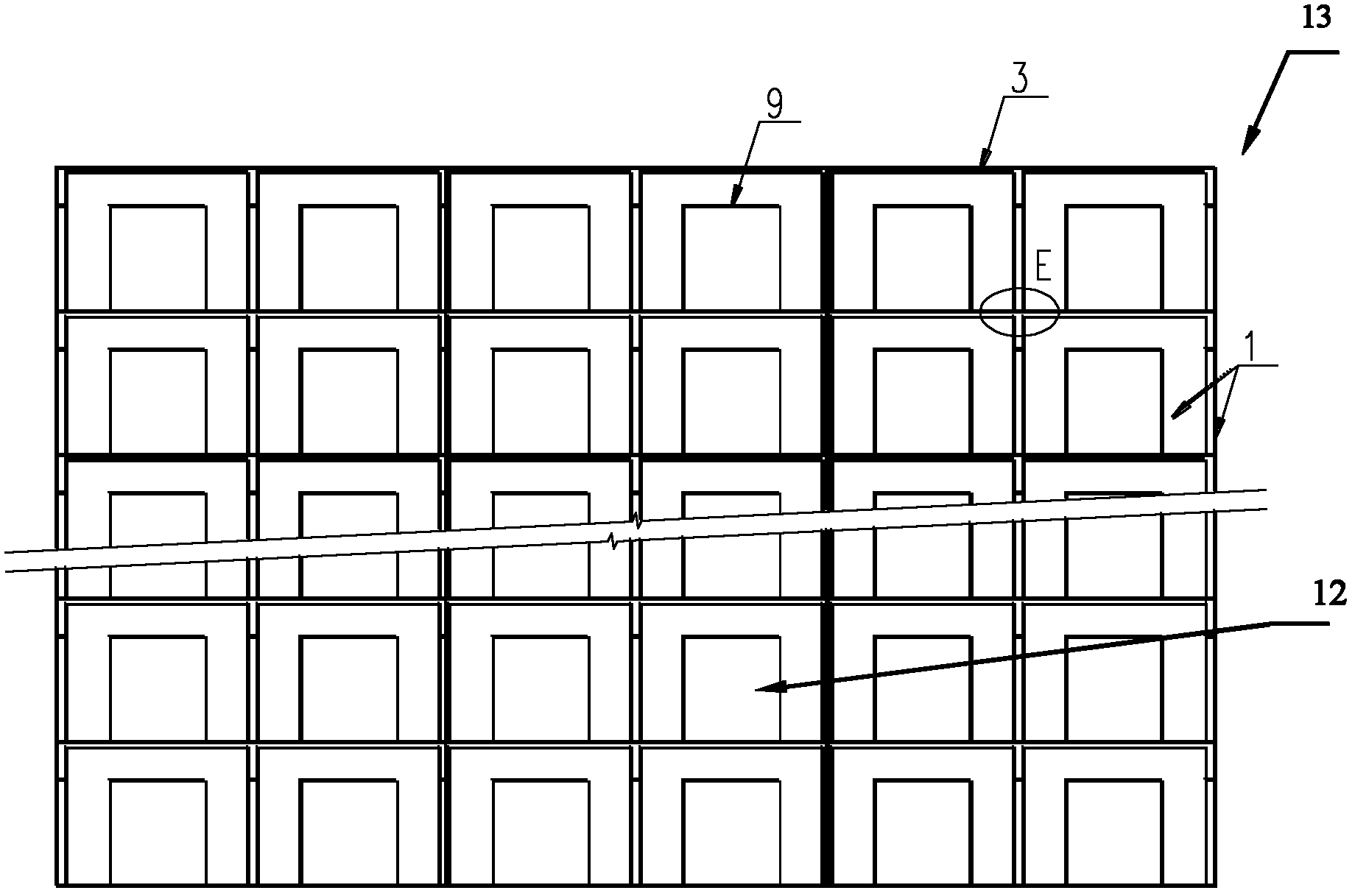

[0039] like Figure 1~4 As shown, a unitary fully assembled prefabricated concrete structure residential system includes several prefabricated units 11 with a single room or multiple rooms as a unit, wherein the prefabricated units are spliced horizontally to form a residential floor 12, and the residential floors 12 are connected vertically A housing system 13 is formed.

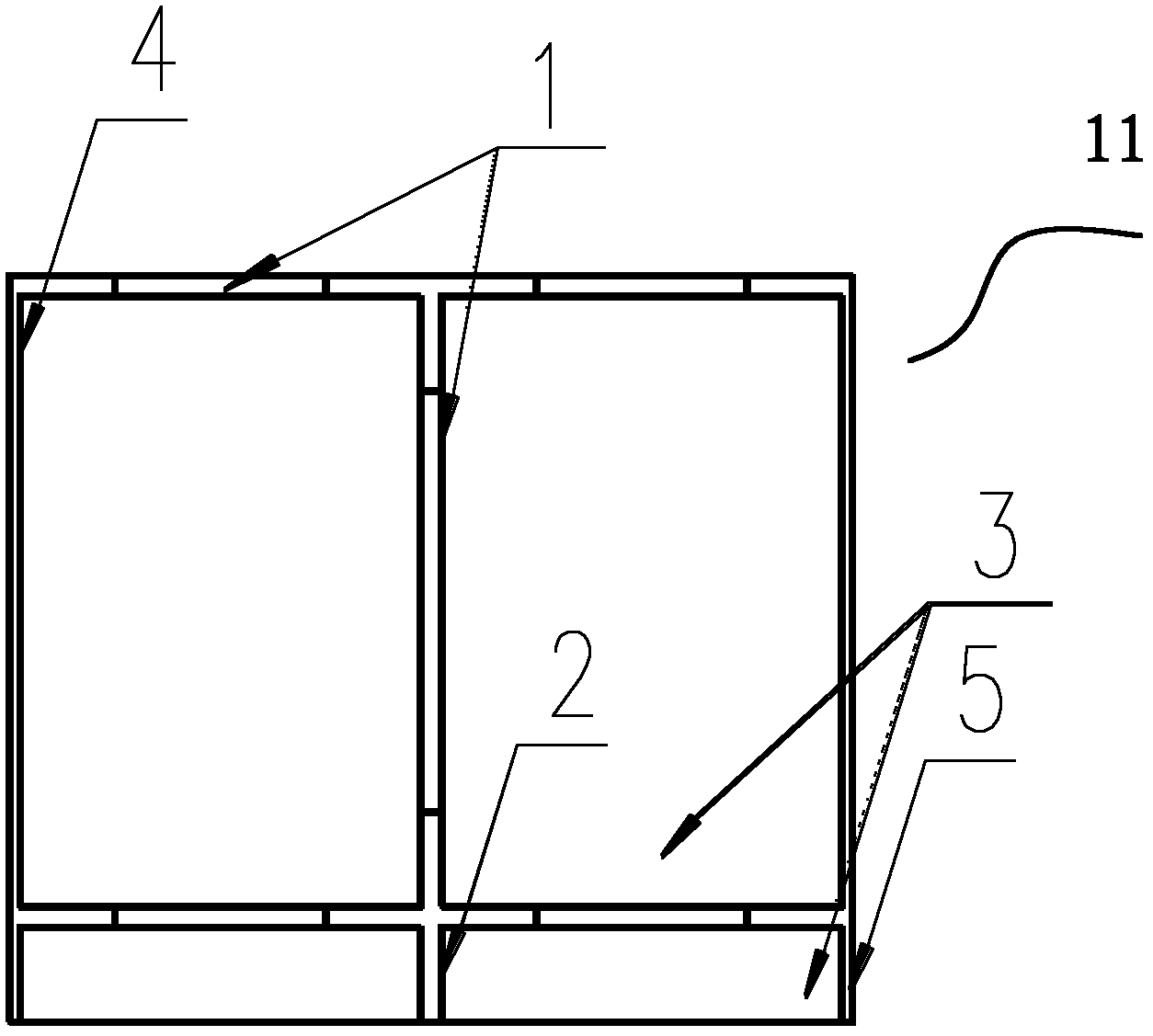

[0040] The prefabricated unit 11 is cast-in-place in the prefabricated factory to form an integral structure with a single room or multiple rooms as the unit according to the needs of the building and structure, which includes the shear wall 1, the floor 3 and the cantilevered half-beam 2. The shear wall 1 of the adjacent prefabricated unit is formed by connecting two half walls 4, and the thickness of the half wall is 1 / 2 of the shear wall. The prefabricated unit 11 is partially pre-embedded with connecting steel plates 7 on the joint surface of the adjacent prefabricated half walls. The prefabricated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com