Method and device for measuring productivity of oil well

A production, oil well technology, applied in the field of oil well measurement, can solve the problems of inaccurate measurement, low phase separation accuracy and low use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

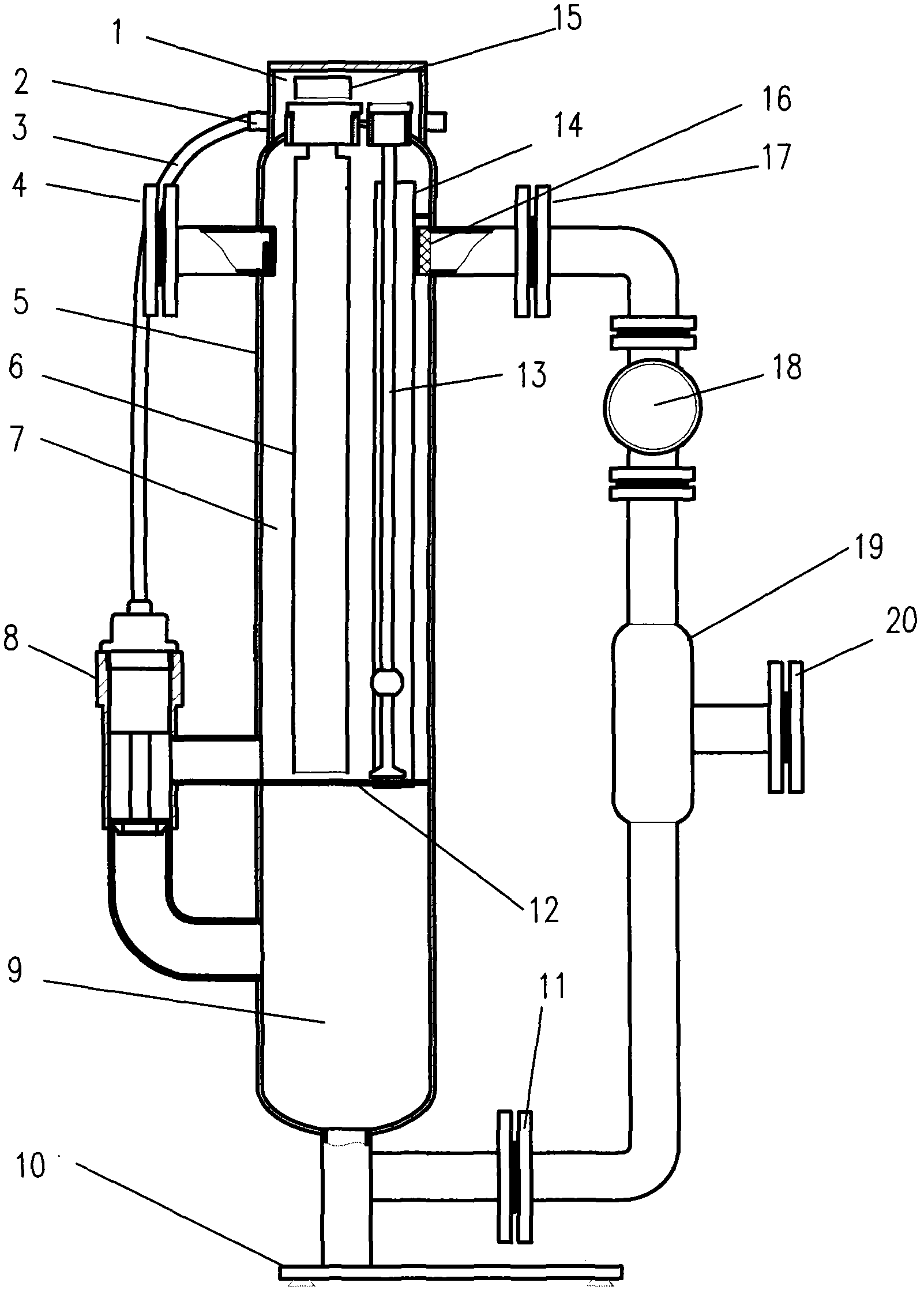

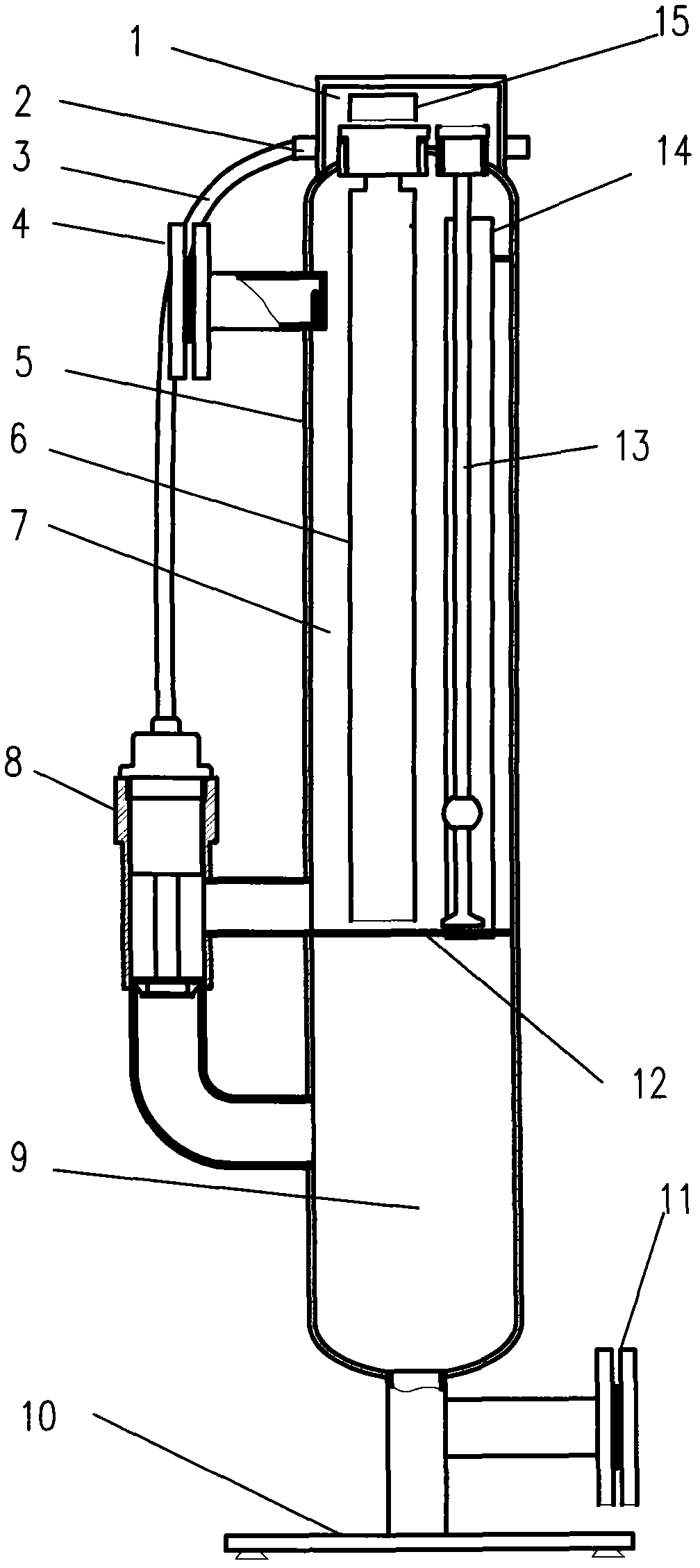

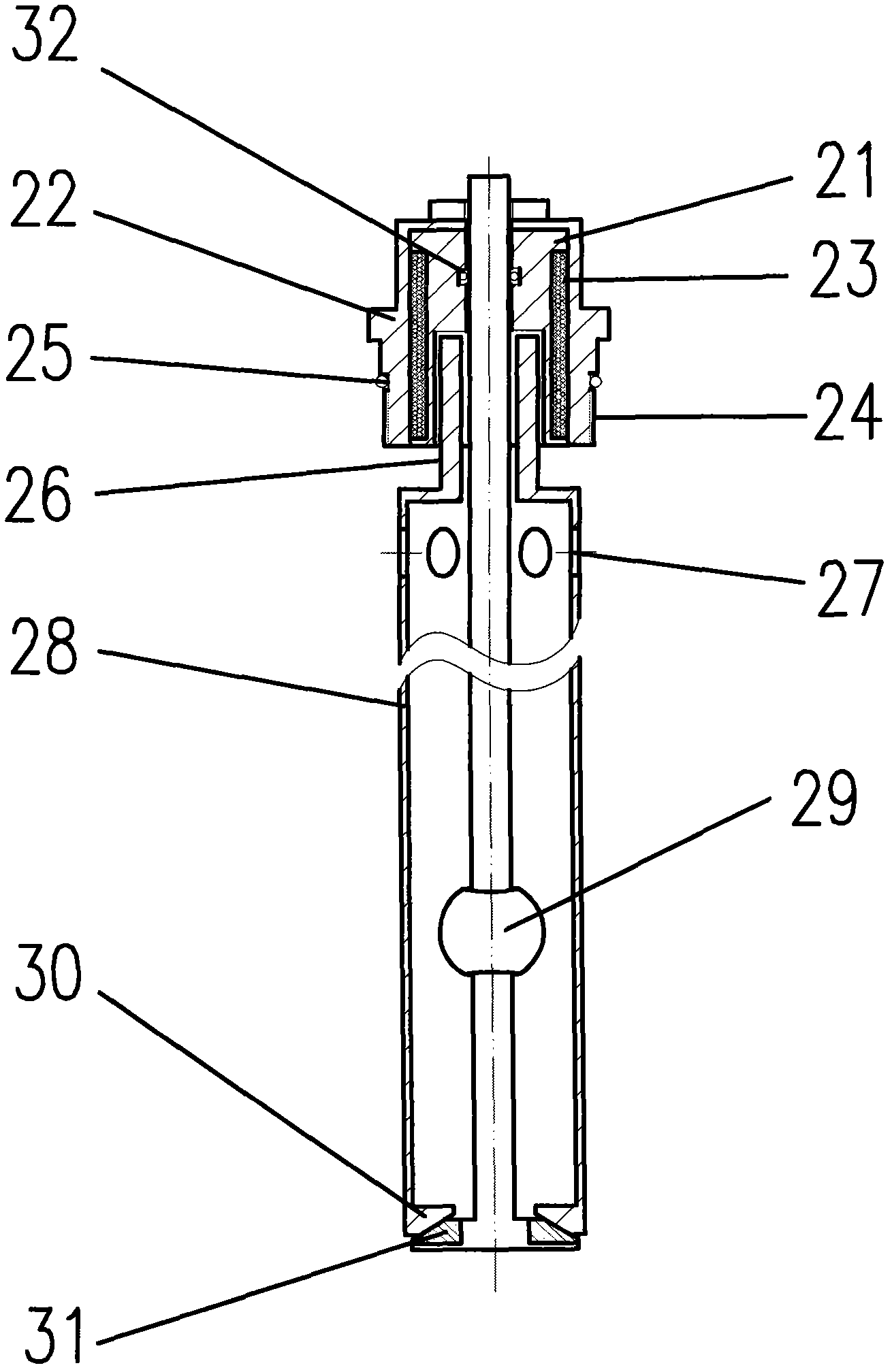

[0019] Three-phase flow measurement method and device such as figure 1 As shown, the gas and liquid produced by the oil well enter the gas-liquid inlet 4 of the device, and when they flow into the measurement chamber 7 of the tank body from the measuring hole, the flow direction of the fluid enters in a tangential direction with the inner wall of the measurement chamber 7, and enters in the measurement chamber 7 Retained in the internal memory, the gas is partially separated and then gathered upwards in the upper part of the cavity through the gas measurement loop (foam metal filter 16, gas outlet 17, gas meter 18, mixer 19, gas-liquid outlet 20) through the gas meter in the loop After metering, it is discharged into the oil pipeline, and the separated liquid part sinks and accumulates in the measurement chamber 7 to produce a change in liquid level. The change in liquid le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com