Wind turbine and a method for pitching a blade of a wind turbine

A technology of wind turbine blades and wind turbines, applied in the control of wind engines, wind engines, machines/engines, etc., can solve problems such as unfavorable load distribution, achieve symmetrical and uniform load distribution, reduce strain, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] Detailed description of related technologies

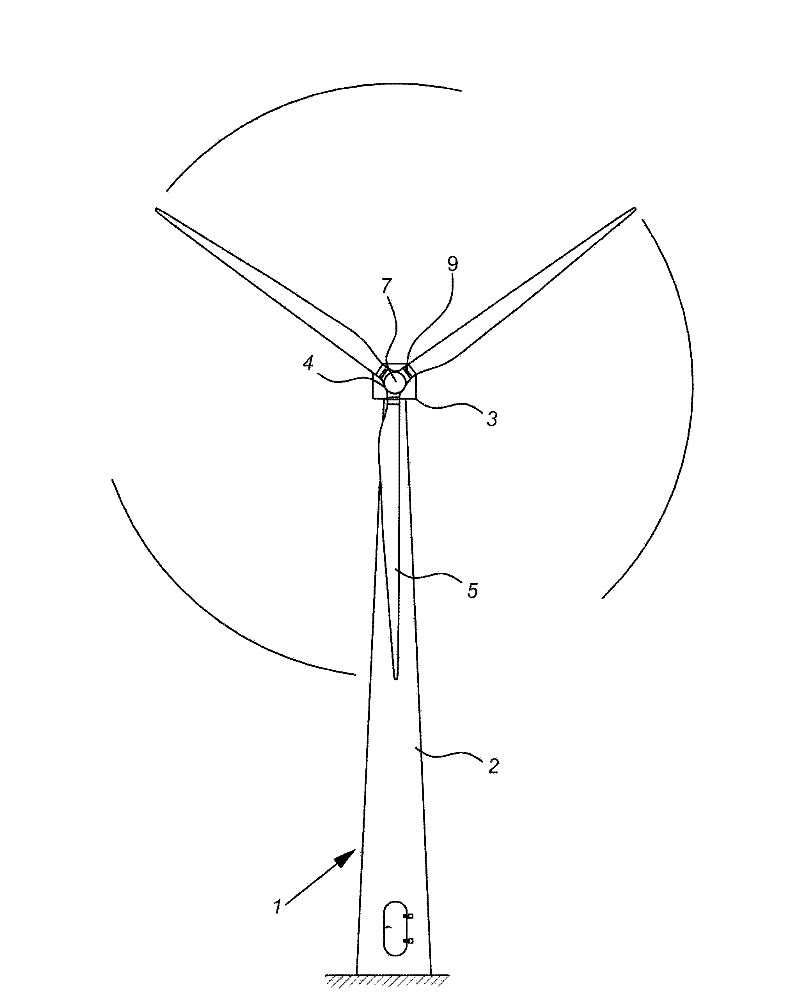

[0096] figure 1 A wind turbine 1 is shown comprising a tower 2 and a wind turbine nacelle 3 on top of the tower 2 . A wind turbine rotor 4 comprising three wind turbine blades 5 is connected to the nacelle 3 via a low speed shaft protruding out of the front of the nacelle 3 .

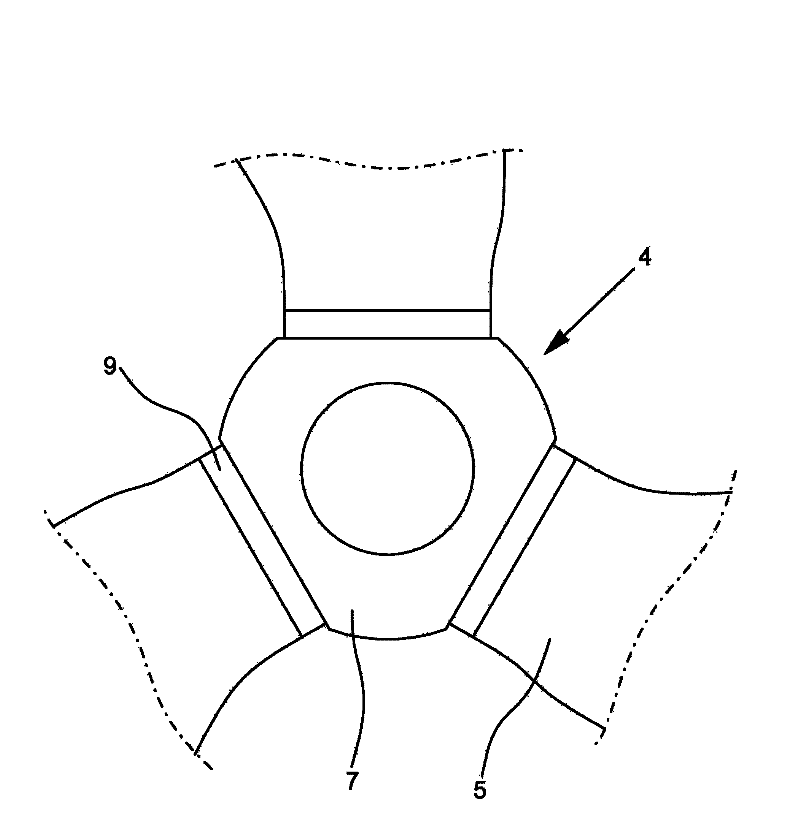

[0097] figure 2 A wind turbine rotor 4 comprising a hub 7 and three blades 5 is shown seen from the front.

[0098]As shown, a pitch bearing 9 is arranged between the blade 5 and the hub 7 to enable the blade 5 to rotate about its longitudinal axis and transmit forces mainly from three different sources. The blade 5 (and of course the bearing 9 itself) is under the constant influence of gravity. The direction of gravity changes depending on the position of the blade 5 , resulting in different loads on the pitch bearing 9 . When the blade is in motion, the bearing 9 is also subject to centrifugal forces which generate mainly axial tension in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com