Binding film for leakage detection of sulfur hexafluoride electric equipment

A technology of electrical equipment and sulfur hexafluoride, which is applied in the field of high-voltage switchgear detection of power systems, can solve the problems of exceeding the gas leakage rate, the leakage detection accuracy is difficult to meet the arbitration, and the annual gas leakage rate error is very large, so as to improve the practical application. performance and reliability, significant economic and social benefits, and easy and fast use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

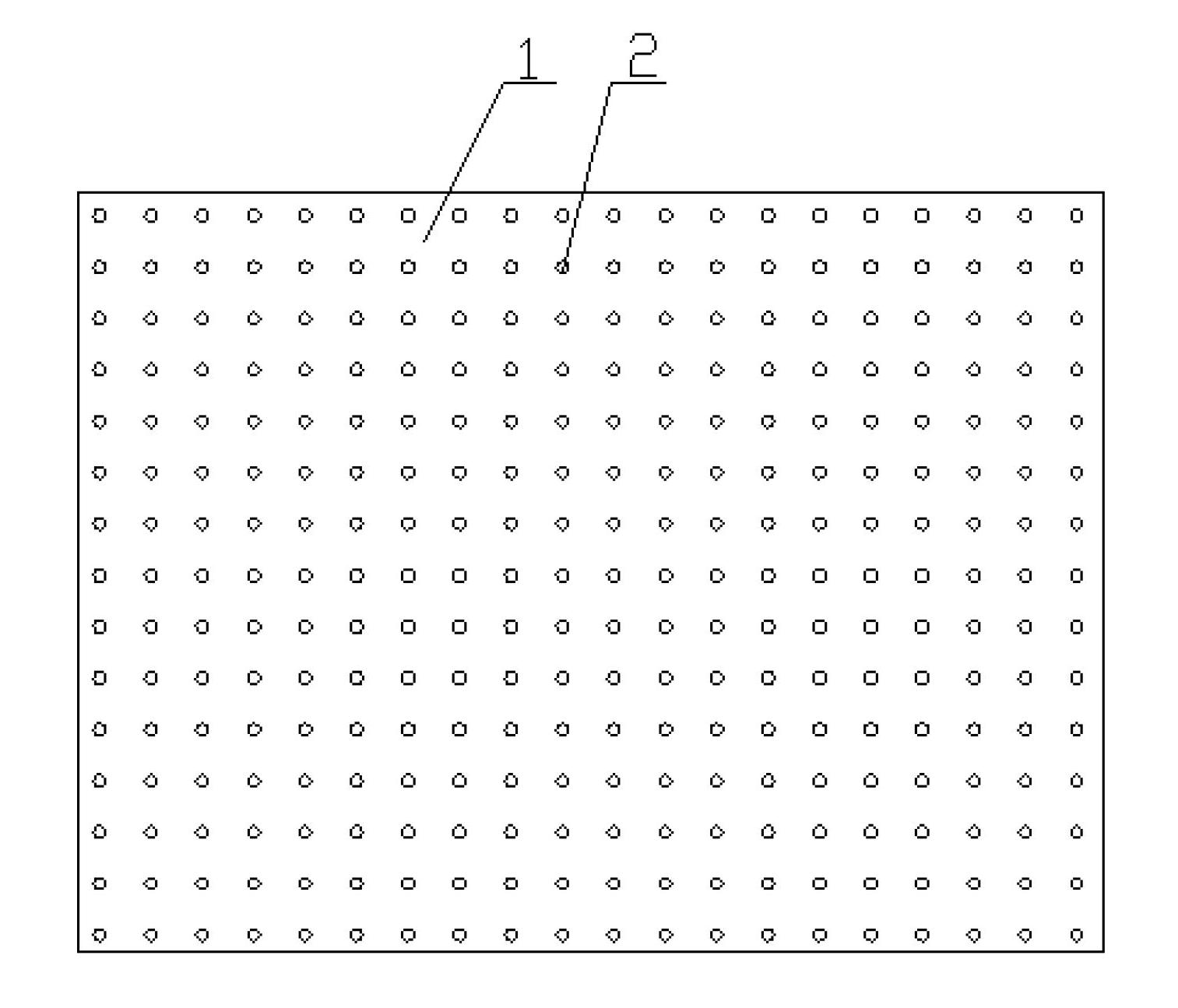

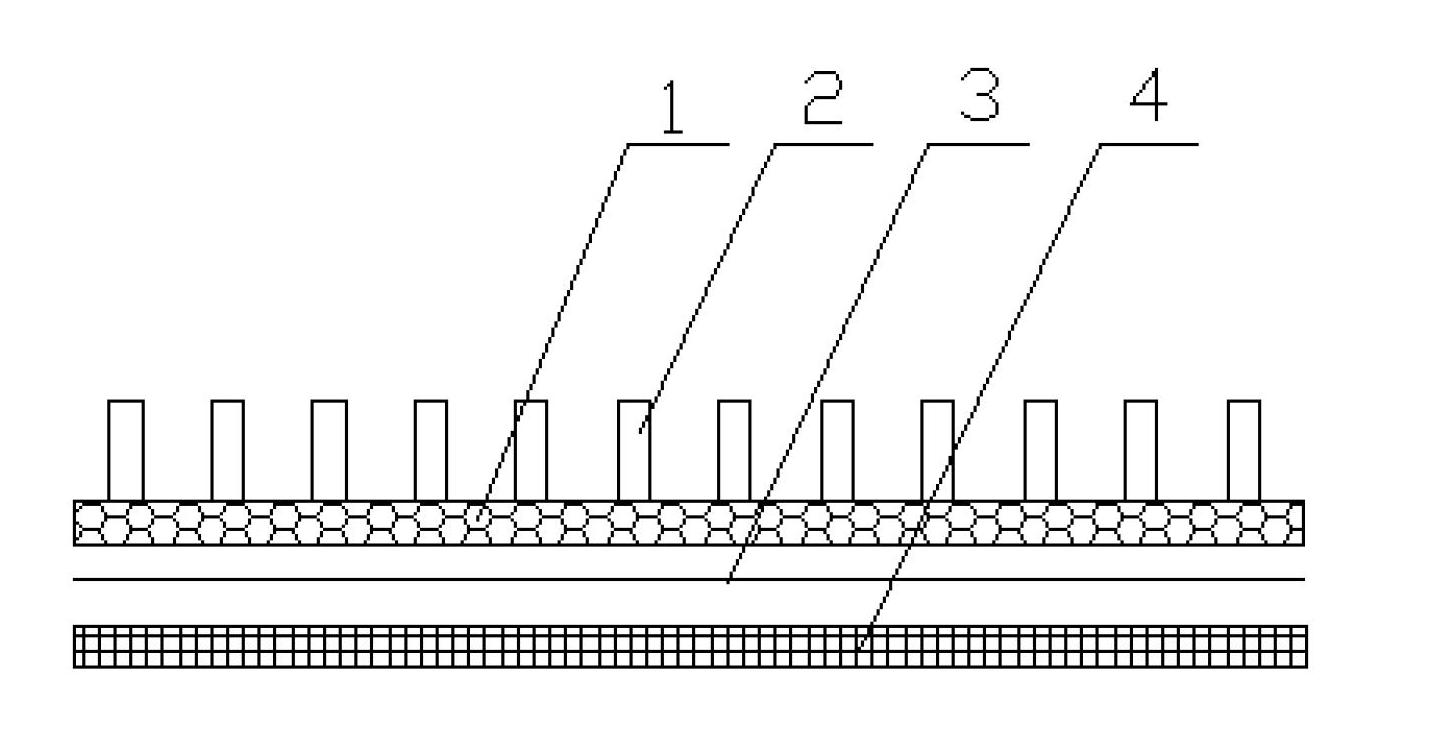

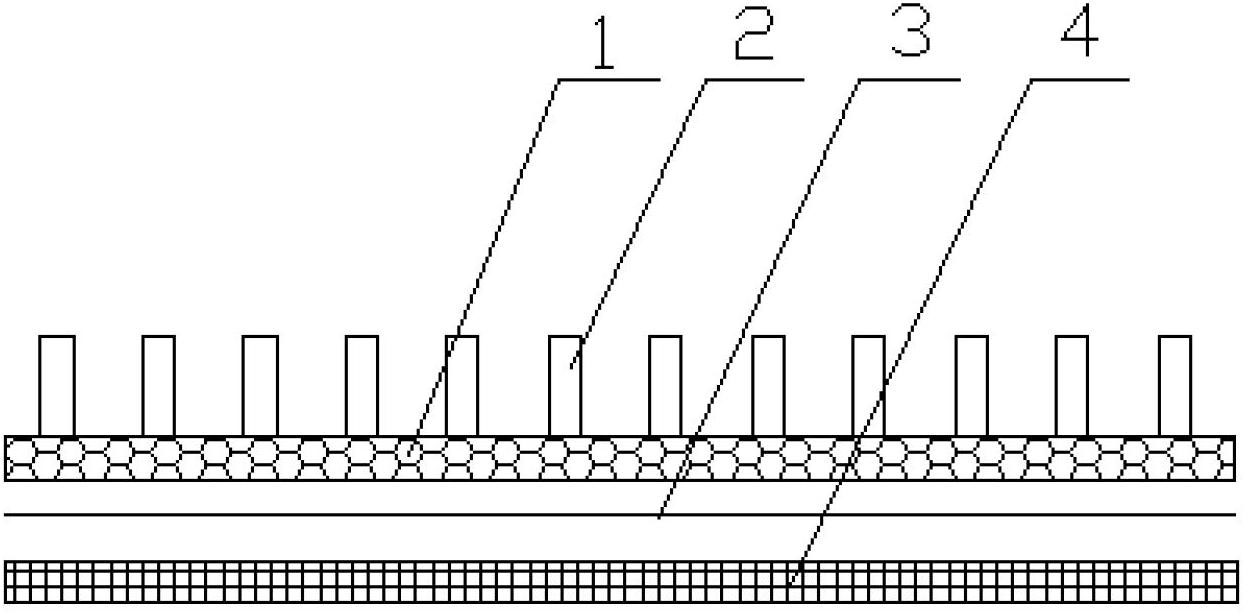

[0018] The thickness of the plastic layer is selected to be 0.2 mm, the diameter of the cylindrical plastic body is 2 mm, the height is 5 mm, the distance between each cylindrical plastic body is 20 mm, and the thickness of the plastic film is 0.05 mm. According to the shape of the tested part, cut the size of the plastic layer, splice out the shape corresponding to the tested part, and then stick the plastic film on the plane side of the plastic layer with double-sided tape to form a whole, and calculate the overall surface area of the plastic layer. Put the cylindrical plastic body of the plastic layer towards the tested part, the top of each cylindrical plastic body is in close contact with the tested part, the plastic layer wraps the tested part, and the wrapping seam is sealed with tape. Calculate the volume of the enveloping cavity through the overall surface area of the plastic layer and the height of the cylindrical plastic body, and subtract the volume of all cylin...

Embodiment 2

[0020] The thickness of the plastic layer is selected to be 0.5 mm, the diameter of the cylindrical plastic body is 5 mm, the height is 20 mm, the distance between each cylindrical plastic body is 50 mm, and the thickness of the plastic film is 0.2 mm. According to the shape of the tested part, cut the size of the plastic layer, splice out the shape corresponding to the tested part, and then paste the plastic film on the plane side of the plastic layer with double-sided tape to form a whole, and calculate the overall surface area of the plastic layer. Put the cylindrical plastic body of the plastic layer towards the tested part, the top of each cylindrical plastic body is in close contact with the tested part, the plastic layer wraps the tested part, and the wrapping seam is sealed with tape. Calculate the volume of the enveloping cavity through the overall surface area of the plastic layer and the height of the cylindrical plastic body, and subtract the volume of all cylin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com