Omni-directional shear horizontal (SH) guided wave electromagnetic ultrasonic transducer

An electromagnetic ultrasonic and transducer technology, which is applied in the direction of material analysis, instruments, and scientific instruments using sonic/ultrasonic/infrasonic waves, and can solve the problems of ferromagnetic materials and non-conductive materials to stimulate ultrasonic waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

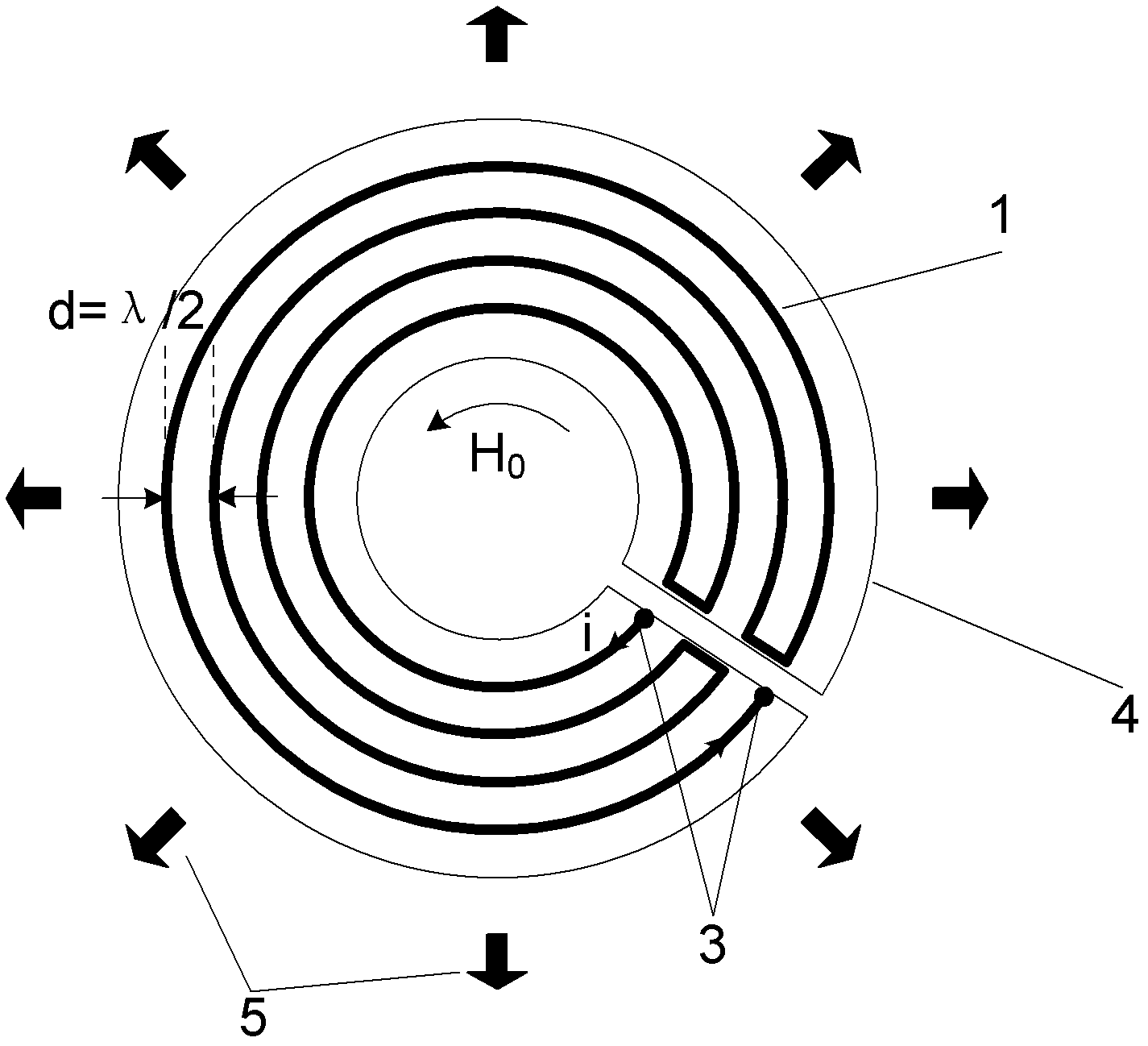

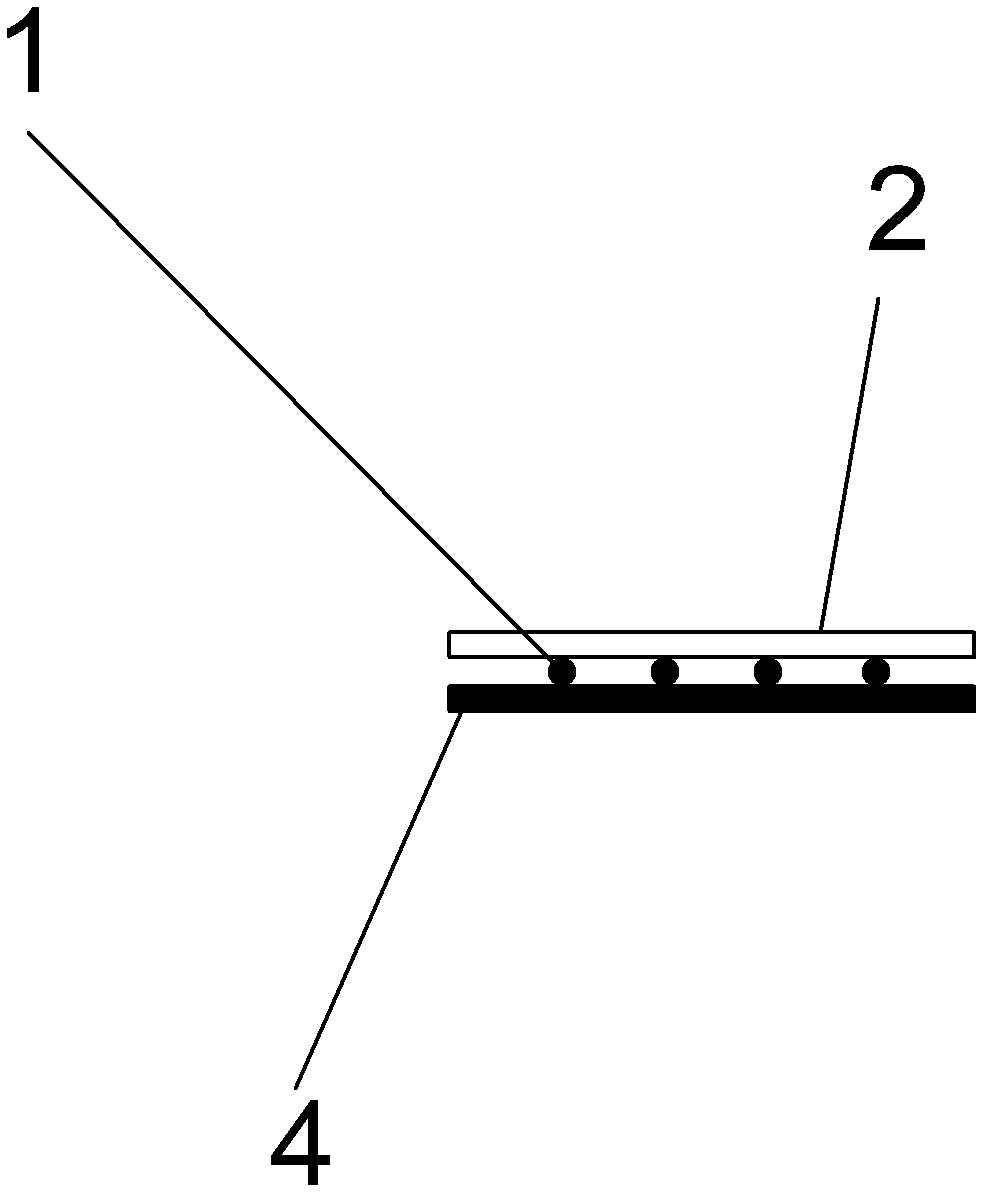

[0024] like figure 1 and figure 2 As shown, an omnidirectional SH guided wave electromagnetic ultrasonic transducer includes an annular iron-nickel alloy strip 4 with an opening. In this embodiment, the thickness of the alloy strip 4 is 0.2 mm, and the opening width is 0.5 mm.

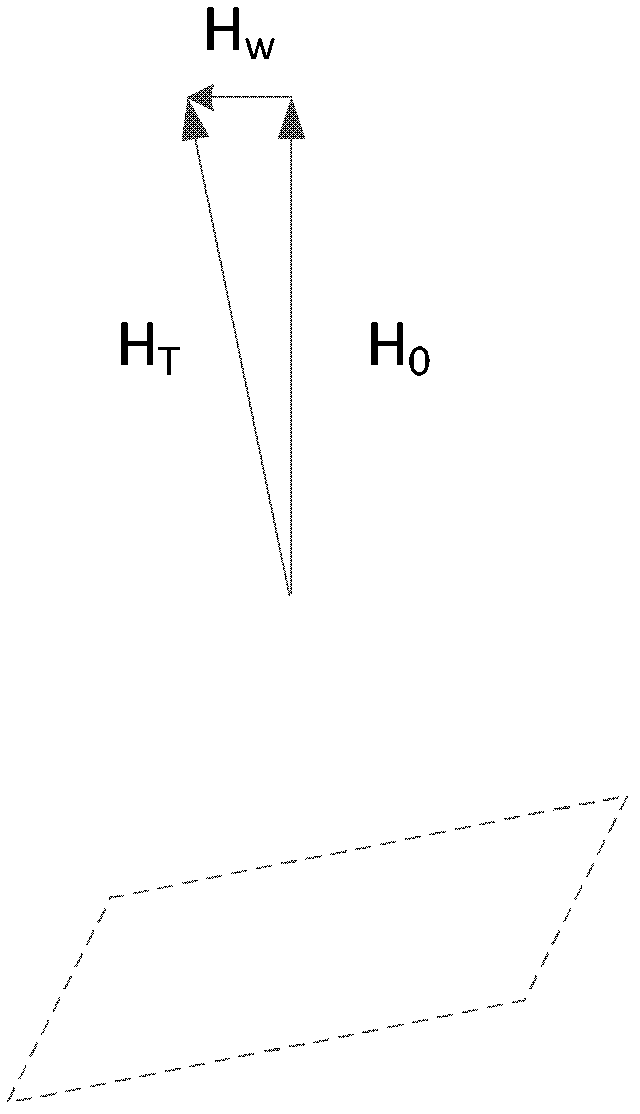

[0025] A folded coil 1 coated with an insulating coating on the surface is built on the PCB substrate 2. After the current is passed into the folded coil 1, the currents of adjacent wires are reversed, and the currents in the separated wires are in the same direction. In this embodiment, each wire of the folded coil 1 is a 3-split split wire, and the radial distance between the centers of two adjacent wires is d=λ / 2, where λ is the SH guided wave mode used at the current frequency wavelength at f.

[0026] Paste the folded coil 1 on one side of the alloy strip 4 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Opening width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com