Method for automatically designing and optimizing railway vertical profile

A technology of automatic design and optimization method, applied in the direction of calculation, special data processing applications, instruments, etc., can solve problems such as affecting the efficiency and quality of railway longitudinal section design, lack of convincing optimization evaluation function, and failure to take repair measures. Enhance practicability and flexibility, fully tap potential, and scientifically design a more reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

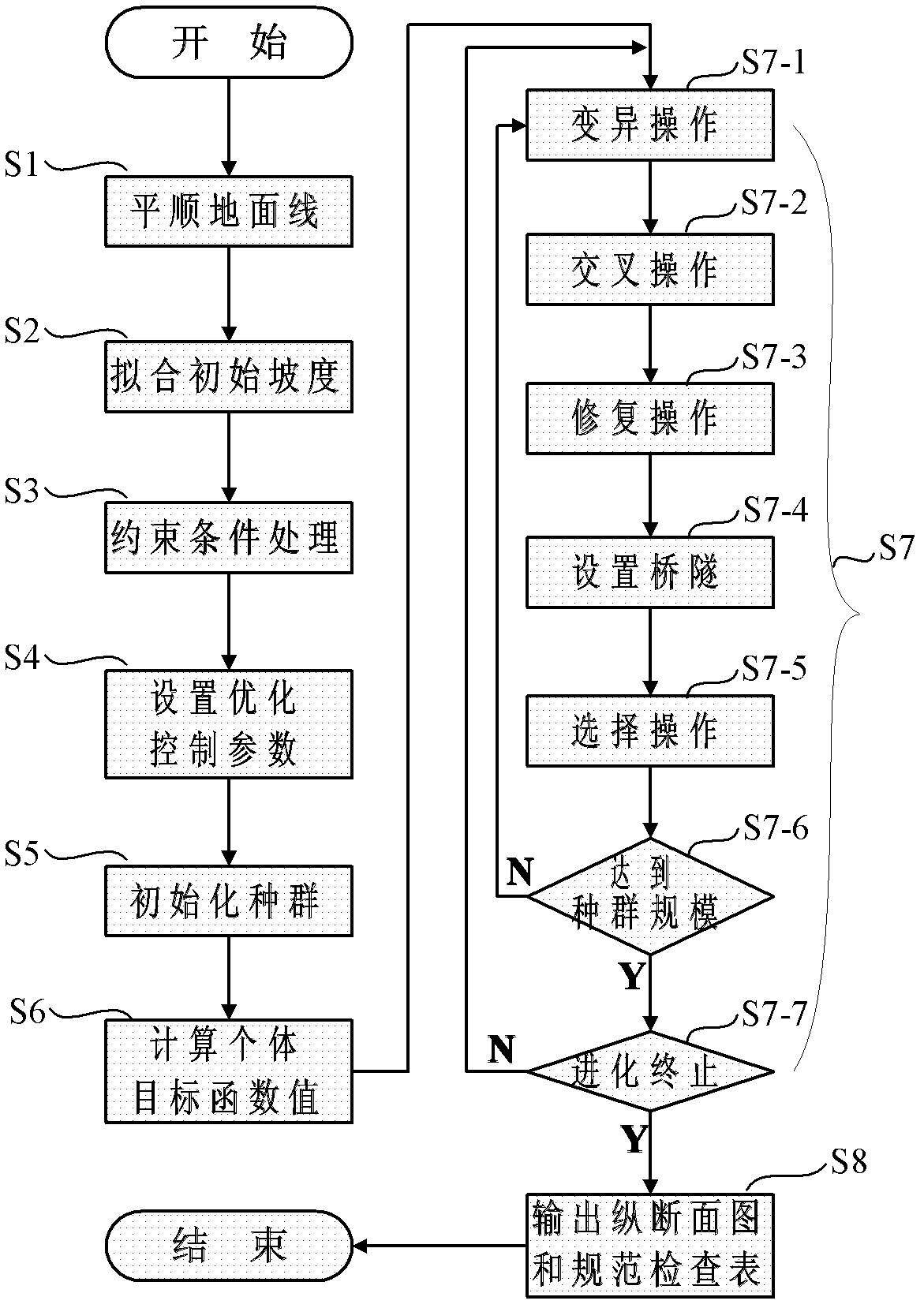

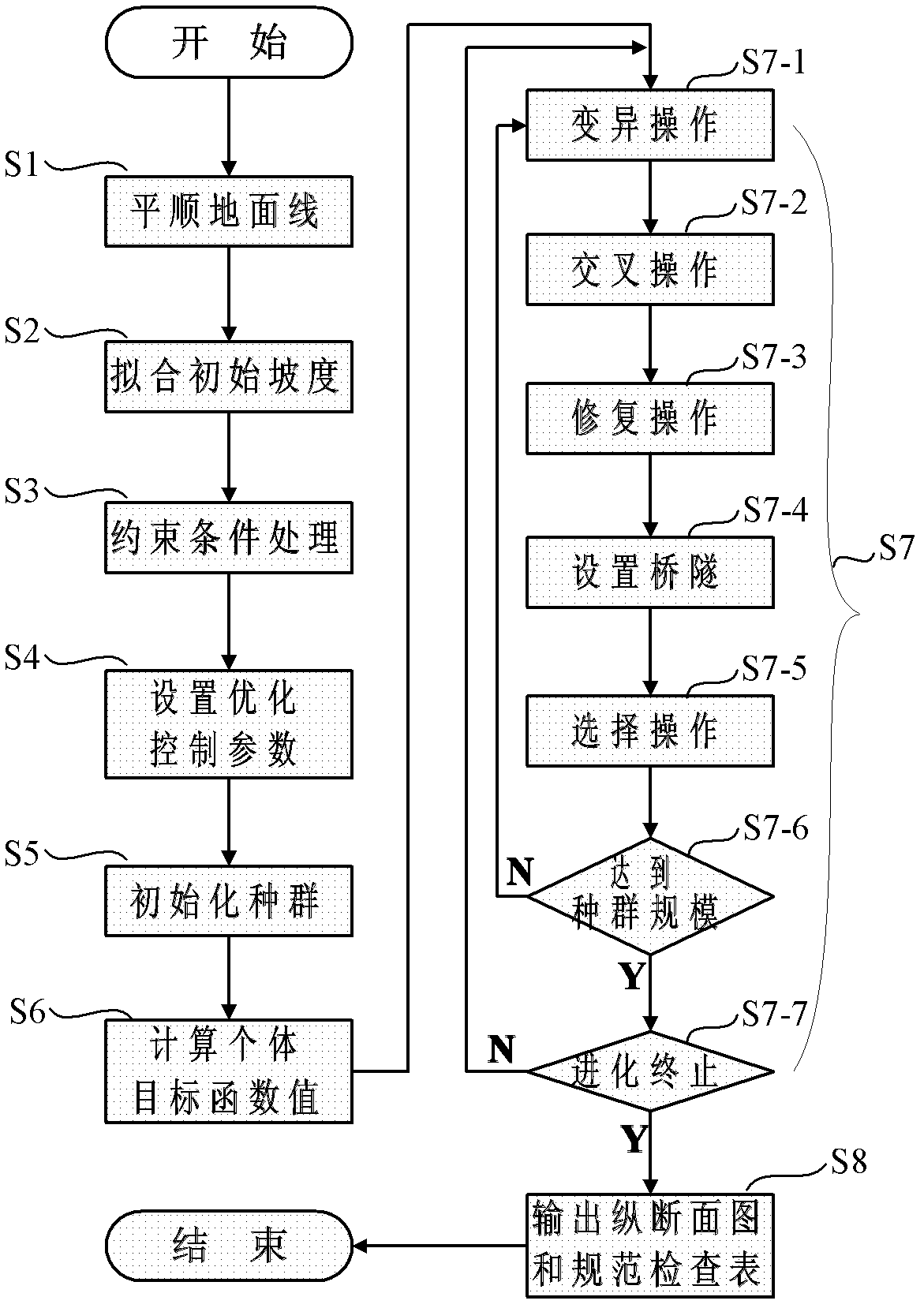

[0043] The technical solution of the present invention will be further described with reference to the accompanying drawings. Such as figure 1 As shown, the railway profile automatic design and optimization method involved in the present invention comprises the following steps:

[0044] S 1 , smooth ground line

[0045] Smooth the original ground line. First, determine the ground line spacing according to the horizontal mapping ratio of the vertical section, use each minimum cell or half a cell as the chainage, interpolate the ground elevation, simplify the ground line according to the method of equidistant processing, and then simplify the ground line Smooth out.

[0046] To smooth the ground line, firstly determine the number of simplified ground points on both sides involved in smoothing within the smooth range of the ground line based on the minimum slope length and the horizontal design ratio of the longitudinal section, and then perform weighting on the simplified grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com