Method for evaluating performance of organic release agent, process for producing mold, and process for producing transparent film with finely roughened structure on surface

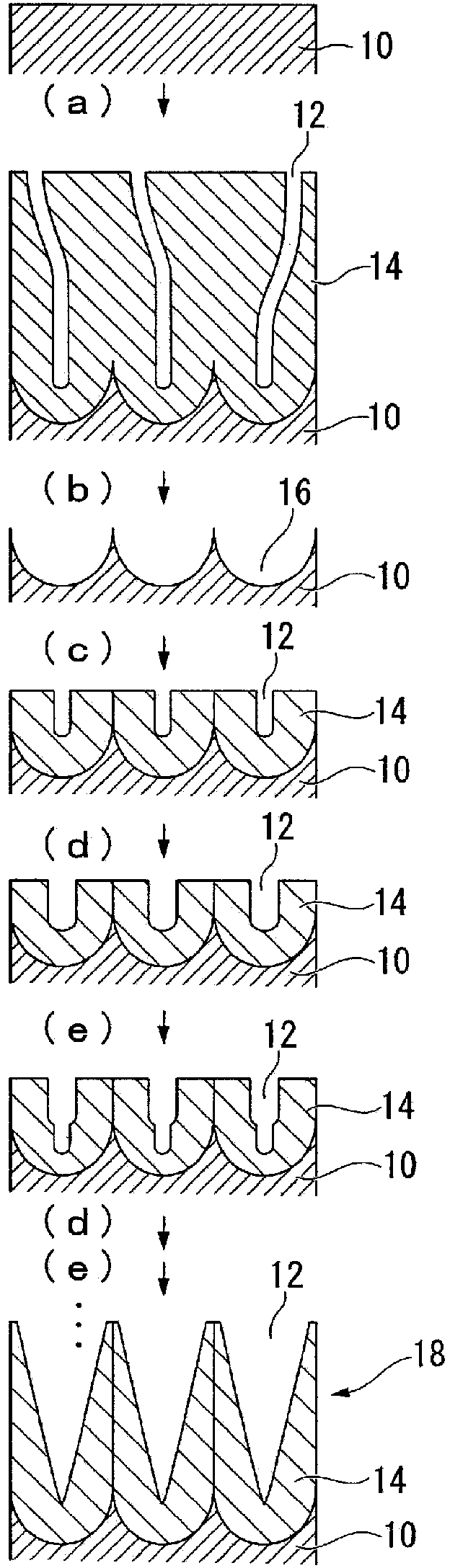

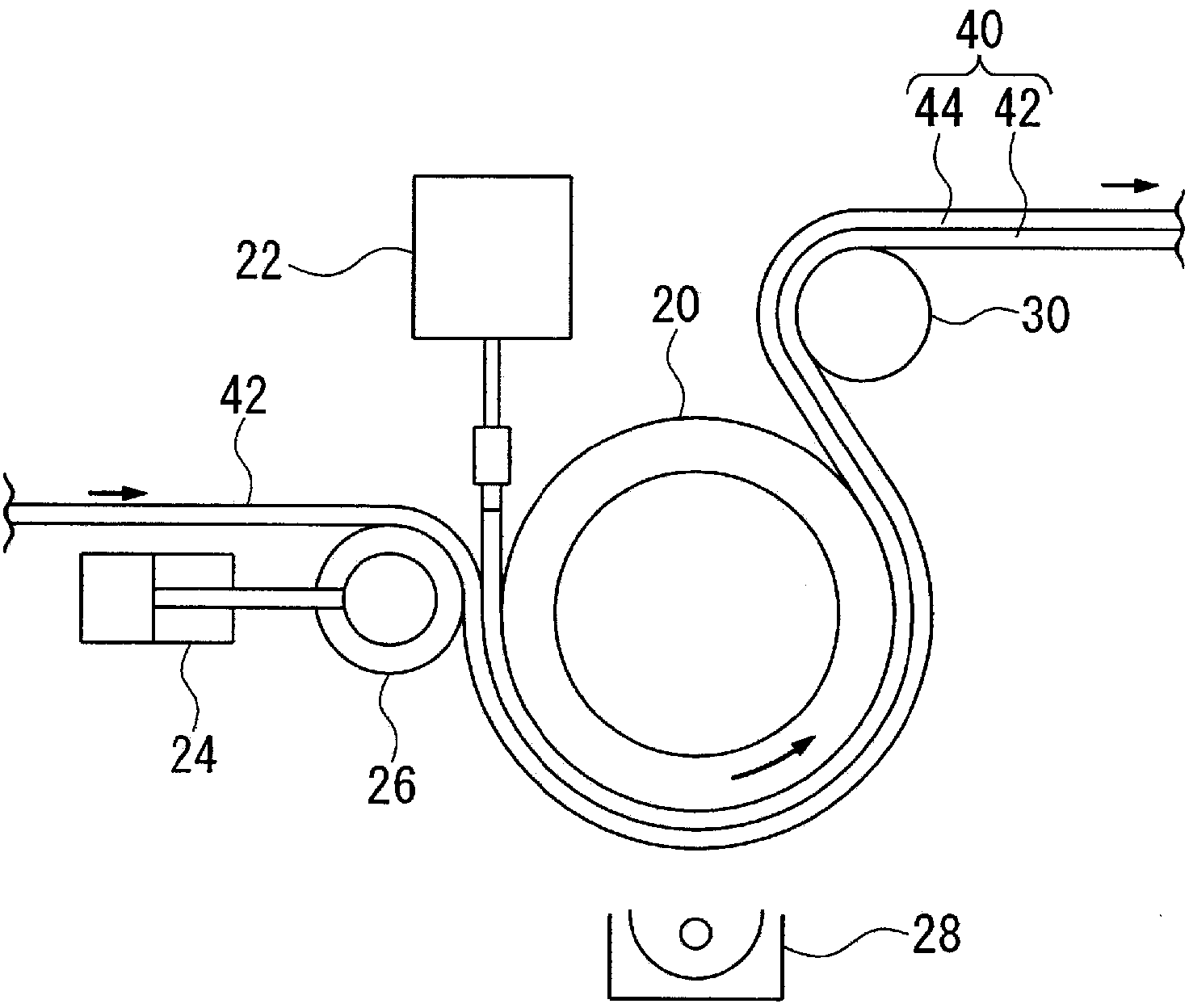

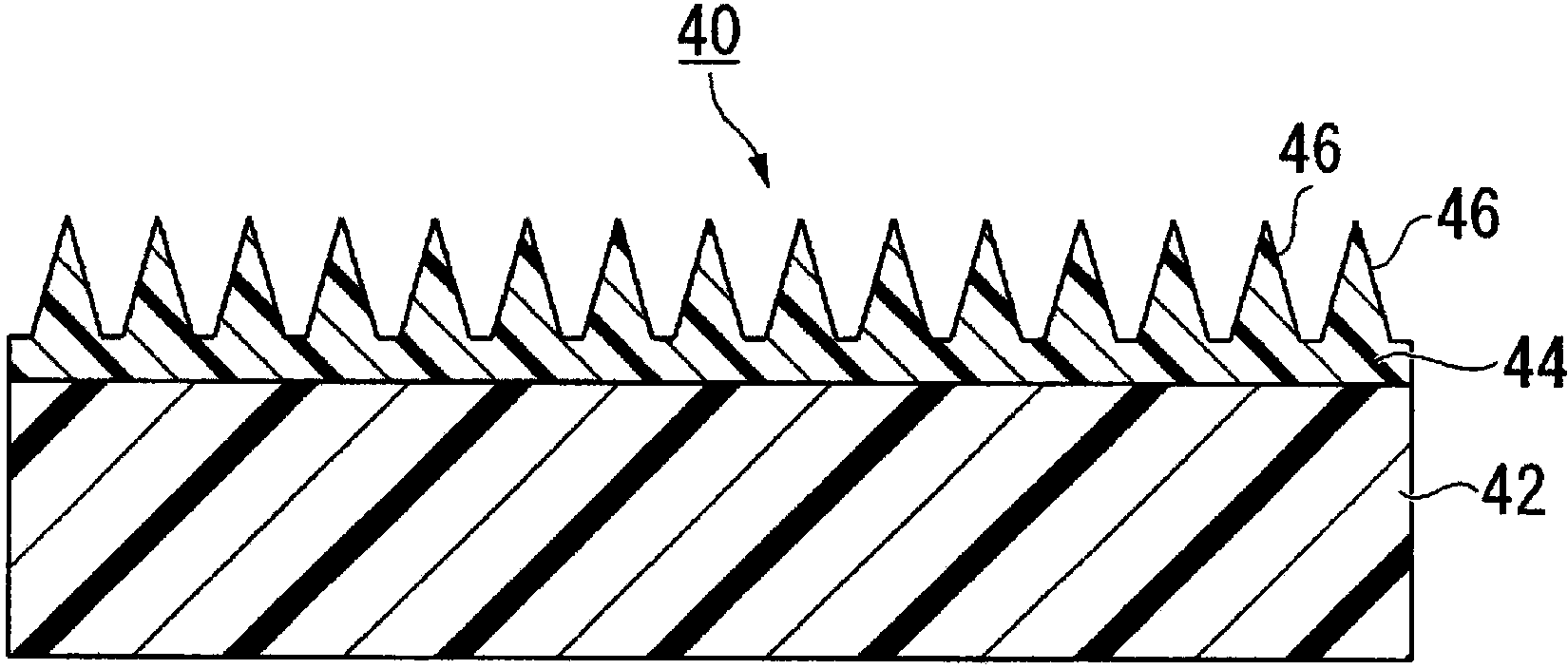

A technology of fine concave-convex structure and manufacturing method, which is applied in the direction of surface reaction electrolytic coating, semiconductor/solid-state device manufacturing, flat products, etc., can solve problems such as deterioration, difficulty in stably manufacturing transparent films, and insufficient surface release properties. The effect of stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example )

[0068] Hereinafter, a case where the organic release agent is a fluorine compound having a hydrolyzable silyl group ["OPTOOL" series, manufactured by DAIKIN INDUSTRIES, Ltd.] will be described in more detail.

[0069] As an organic solvent for testing, from the viewpoint of increasing the difference in solubility (light transmittance when forming a mixture) between the normal "OPTOOL" series and the deteriorated "OPTOOL" series, N,N-Dimethylformamide is particularly preferred.

[0070] As the organic solvent for dilution, a fluorine-based organic solvent DURASURF HD-ZV (manufactured by Harves Co., Ltd.) is preferable from the viewpoint of the solubility of the organic mold release agent.

[0071] When the concentration of "OPTOOL" series in the mixture of the release agent solution and the organic solvent for the test is too high or too low, it is difficult to express the poor solubility corresponding to the deterioration. Therefore, the mixing ratio of 0.1% by mass release a...

Embodiment 1)

[0260] (Preparation of release agent solution)

[0261] Using OPTOOL DSX (manufactured by DAIKIN INDUSTRIES, Ltd.) as an organic mold release agent, and using DURASURF HD-ZV (manufactured by HARVES Co., Ltd.) as an organic solvent for dilution, a mold release agent concentration of 0.1 mass % was prepared. agent solution.

[0262] (Evaluation of release agent performance)

[0263] The prepared release agent solution was mixed with N,N-dimethylformamide (manufactured by Wako Pure Chemical Industries, Ltd., special grade, dielectric constant (25° C.): 36.71) at a volume ratio of 1:1 to form a mixture. The light transmittance of the mixture was measured with a spectrophotometer (manufactured by Hitachi, Ltd., U-3300). As a reference, a mixture of DURASURF HD-ZV and N,N-dimethylformamide in a volume ratio of 1:1 was used. As a measurement result, the light transmittance at a wavelength of 400 nm was 93%.

[0264] (manufacturing of molds)

[0265] The aluminum plate (purity 99...

Embodiment 2)

[0297] The release agent solution of Example 1 was not replaced, and the surface treatment of the mold main body a was repeated 10 times with the same release agent solution, and the release agent solution and the same N,N-dimethyl formazan as in Example 1 were measured. The light transmittance of the 1:1 volume ratio mixture of amides, as a result, the light transmittance at a wavelength of 400nm is 80%.

[0298] Except having used the above-mentioned release agent solution, it carried out similarly to Example 1, and transferred the fine uneven|corrugated structure of a mold to an acrylic film. The stripping can be carried out smoothly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com