Plastic component, in particular plastic suds container, and method for producing the plastic component

A technology of plastic components and plastic buckets, applied in the field of plastic components, can solve problems such as insufficient space for geometric shapes, inability to apply bearing retainers, material growth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

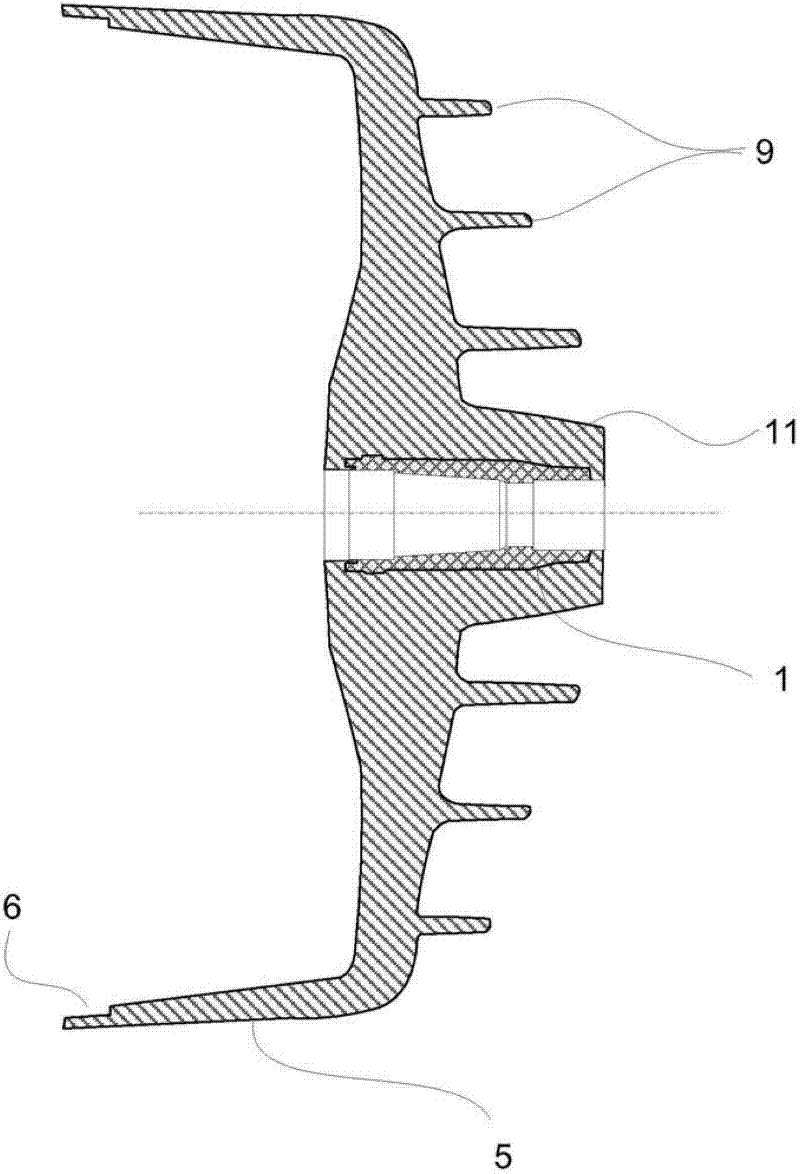

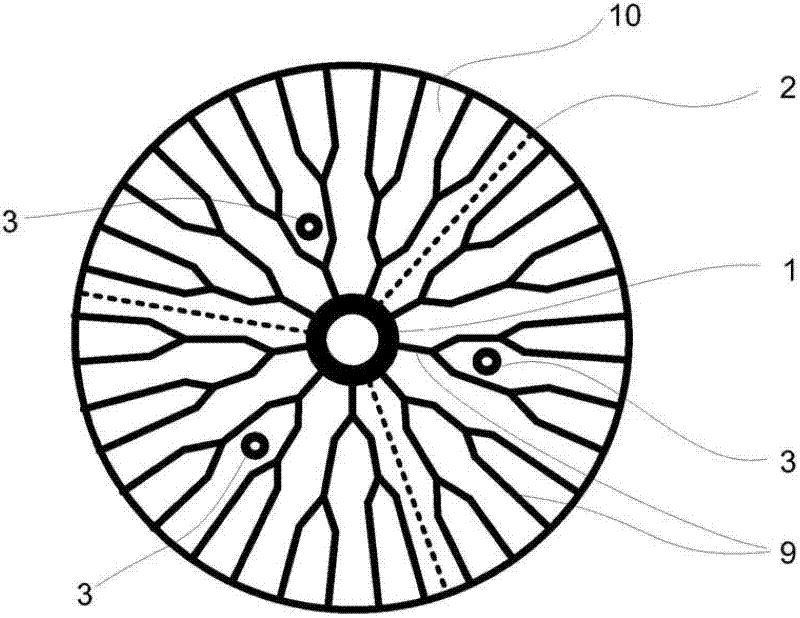

[0031] figure 1A sectional view through the drum axis 6 at right angles to the tub side wall produced in one piece using the injection molding method is shown. The embodiment shown in this figure comprises a rear wall 10 of the tub with a bearing holder 1 for the drum shaft, a transition area 5 to the cylindrical tub shell, for engaging and threading the tub shell The retainer 12 and the molded reinforcing rib 9. The thickness of the side walls 10 as well as the height of the reinforcing ribs 9 decrease from the bearing holder 1 to the tub shell for strength reasons. The tub side wall 10 has three joint lines 2 extending radially outward from the bearing holder 1 to the edge in a straight line. Bonding wires 2 are shown in dashed lines in all figures.

[0032] figure 2 A top view of the tub side wall 10 is shown. In this view, the buckets provided here are no different than those of prior embodiments. Special features of the bondline 2 that characterizes the barrel can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com