Nitriding process for maraging steel

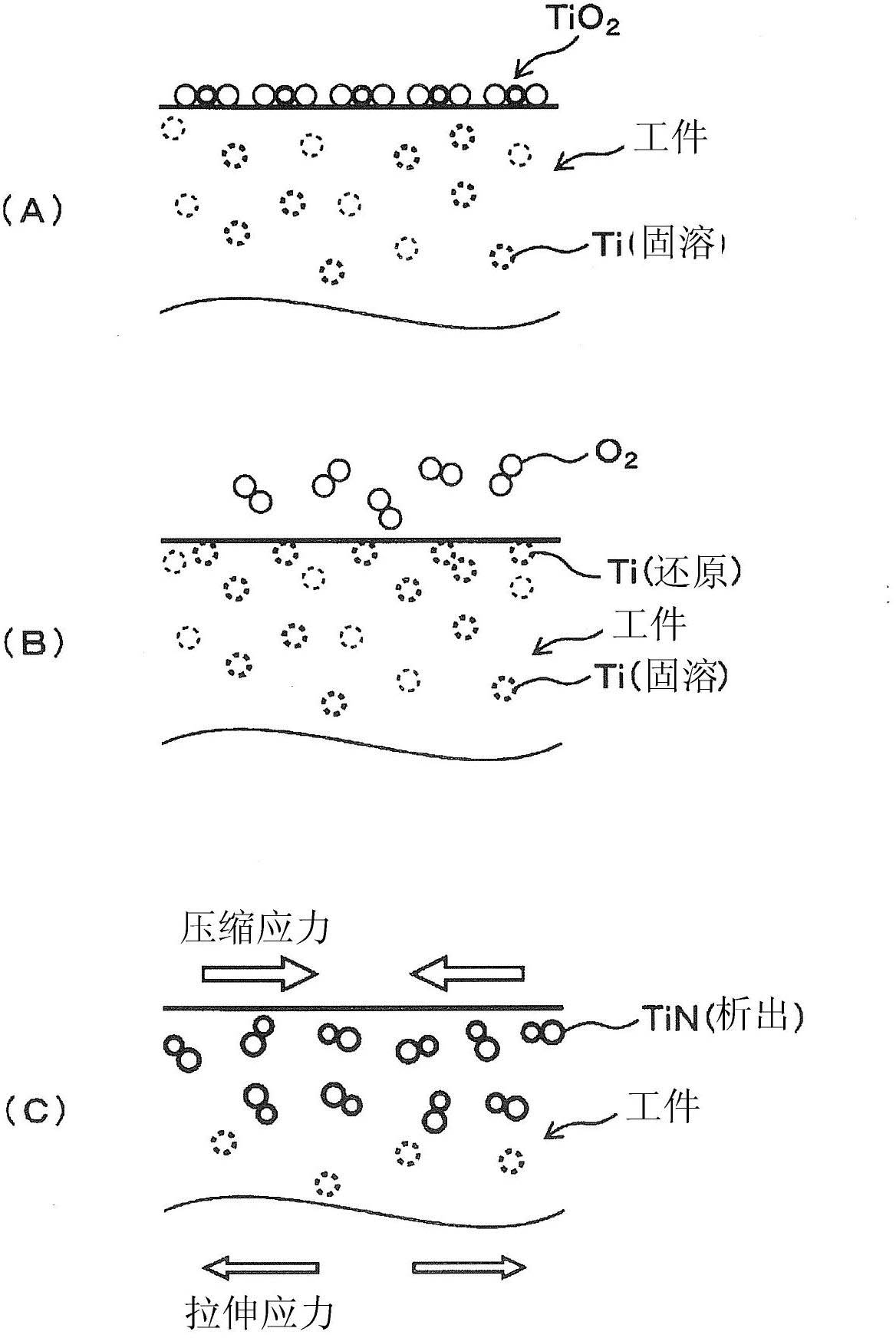

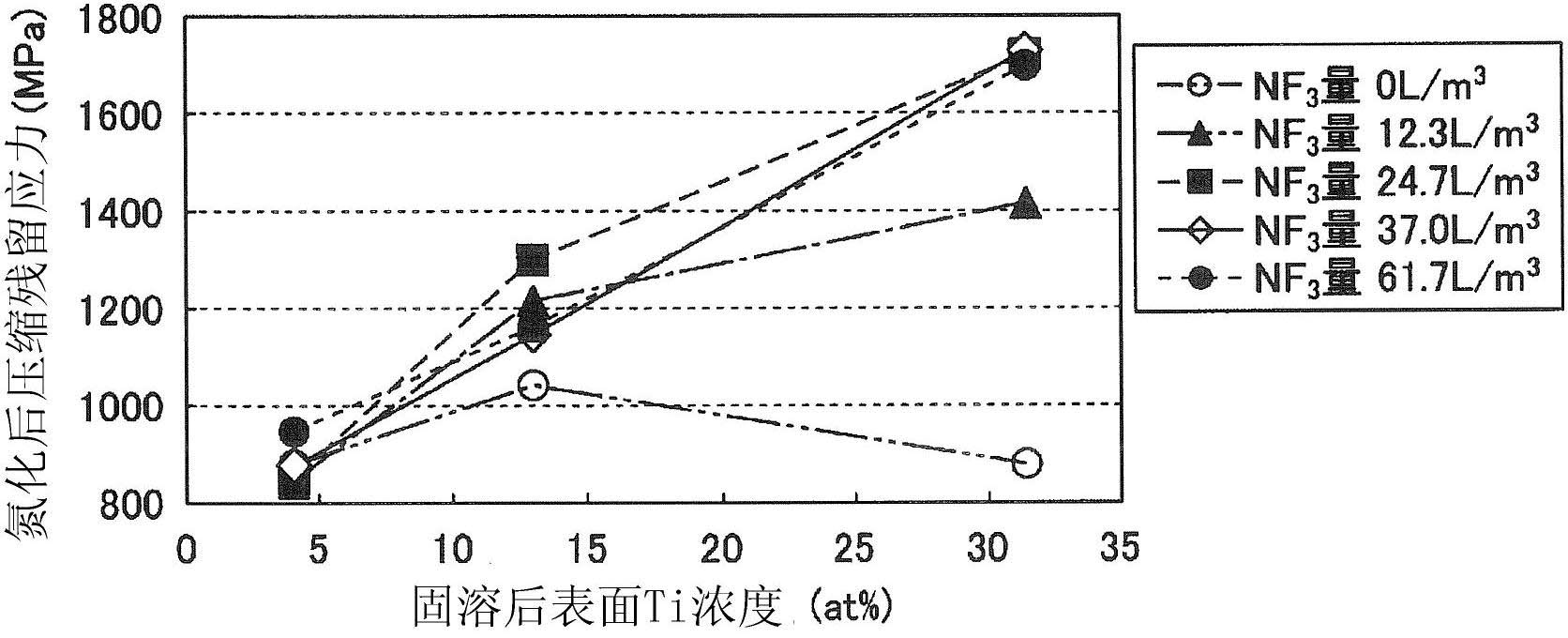

A maraging steel, nitriding treatment technology, applied in the direction of heat treatment furnace, heat treatment equipment, coating, etc., can solve the problems of limited compression residual stress increase, insufficient reduction treatment, etc., achieve high compression residual stress, promote nitrogen The effect of increasing the concentration of the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

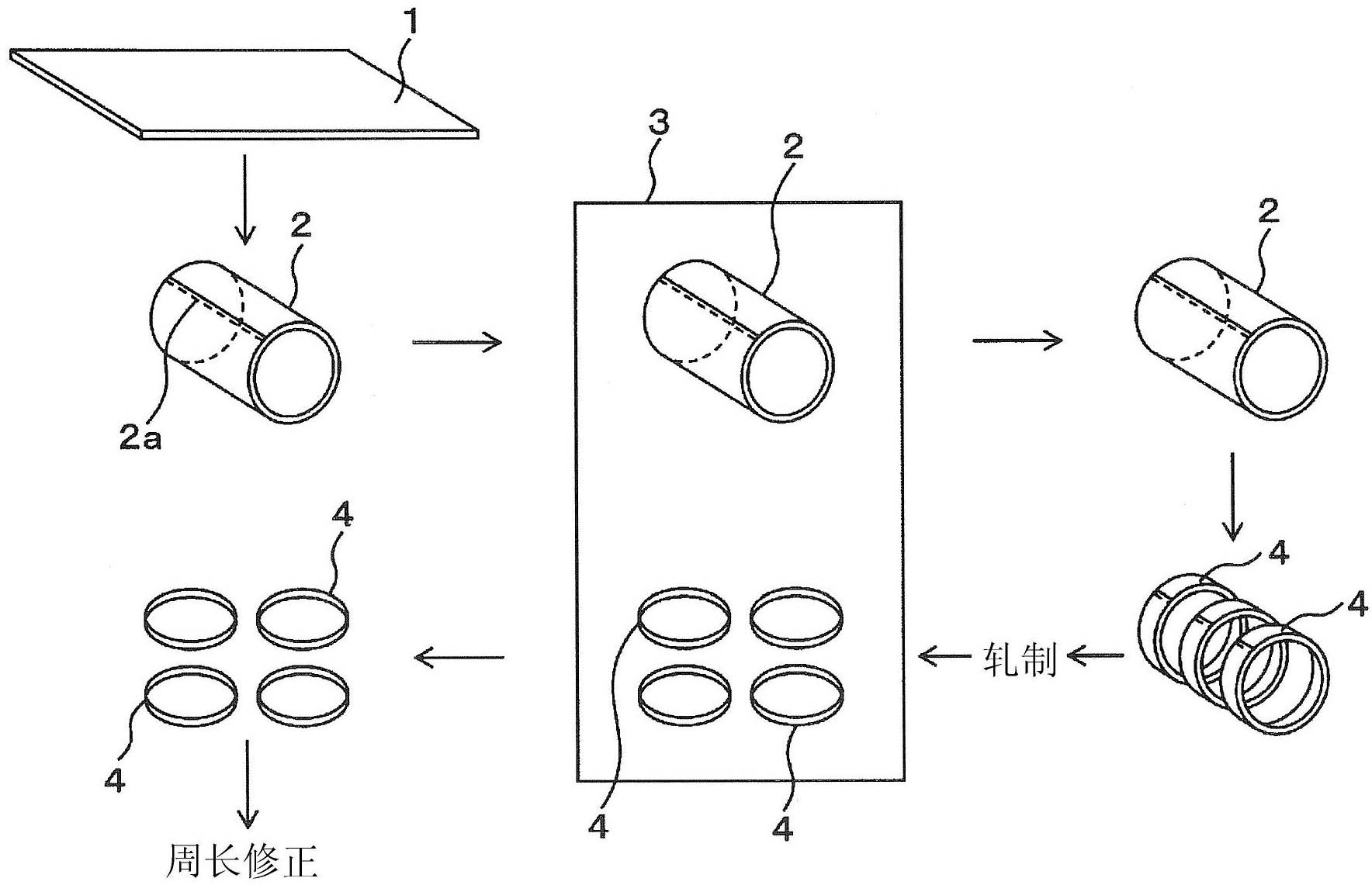

[0023] Hereinafter, the present invention will be described in detail with reference to specific examples. In the examples, the method of nitriding treatment of maraging steel according to the present invention was applied to the method of manufacturing an endless metal belt.

[0024] In the manufacture of endless metal belts, such as figure 2 As shown, first, a thin plate 1 made of maraging steel is formed into a cylindrical shape by welding both ends of the thin plate 1 to form a drum 2 (welding process). At this time, due to the heat of welding, a part 2a of the drum 2 is hardened. Therefore, by performing the first solid solution treatment on the drum 2 in the heating furnace 3, the hardness of the drum 2 is homogenized (first solution treatment). process). Next, the drum 2 is cut to a predetermined width to form a plurality of endless belt-shaped rings 4 (drum cutting step). Next, the ring 4 is rolled to a predetermined thickness (ring rolling process). At this time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com