A boron process suitable for p+ selective emitter cells

An emitter-selective technology that can be used in circuits, electrical components, climate sustainability, etc., to solve battery open-circuit voltage and short-circuit current limitations, boron selective doping diffusion technology blank, non-metallic electrode contact area compounding, etc. It can improve the open-circuit voltage and short-circuit current, facilitate laser doping, and improve the fill factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

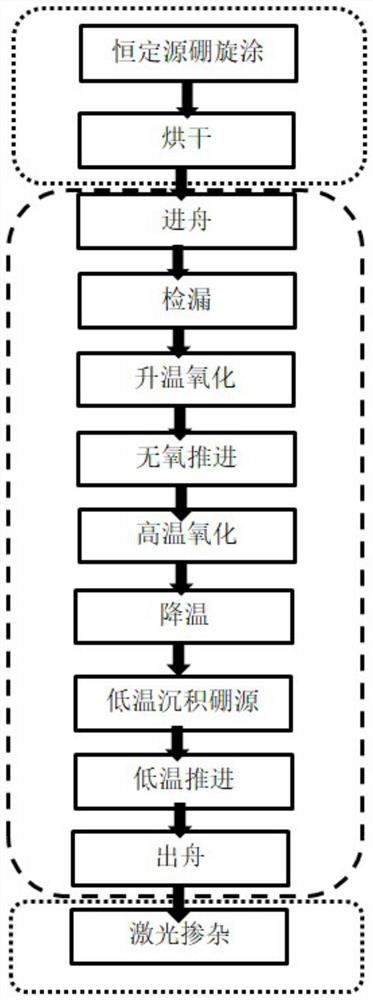

[0048] A constant source boron diffusion process suitable for P+ selective emitter batteries, the specific process is as follows: use N-type silicon wafers with high minority carrier life, resistivity 0.2-2Ω.cm, double-sided alkali washing for texture;

[0049] (1) Constant source boron spin-coating—use 1-1.5mL of immersion solution to spin on the silicon wafer, and then drop 0.4-0.8ml of boron source to spin on the silicon wafer. The spin coating method can produce a higher square resistance of 120-140ohm, and the uniformity STD<8;

[0050] (2) Drying—on a chain machine at a temperature of 120-200°C and a drying time of 30-60s;

[0051] (3) Entering the boat - the temperature is maintained at 750-850°C, the nitrogen flow rate is 1000-2000sccm, and the time is about 8-15min;

[0052] (4) Leak detection - the flow rate of nitrogen gas is 1000-1500sccm, and the pressure is controlled at 100-200pa;

[0053] (5) Heating Oxidation—The temperature rises to 900-960°C, the nitrogen ...

Embodiment 2

[0063] A constant source boron diffusion process suitable for P+ selective emitter batteries, the specific process is as follows: use N-type silicon wafers with high minority carrier life, resistivity 2-6Ω.cm, double-sided alkali-washed texture;

[0064] (1) Constant source boron spin-coating—use 1.5-2.5mL of immersion solution to spin on the silicon wafer by spin-coating, and then drop 0.3-0.6ml of boron source to spin on the silicon wafer. The spin coating method can produce a higher square resistance of 130-200ohm, and the uniformity STD: 9-10;

[0065] (2) Drying—on a chain machine at a temperature of 180-250°C and a drying time of 40-80s;

[0066] (3) Entering the boat - the temperature is maintained at 750-850°C, the nitrogen flow rate is 1500-2500sccm, and the time is about 6-15min;

[0067] (4) Leak detection - the nitrogen flow rate is 1500-2500sccm, and the pressure is controlled at 100-200pa;

[0068] (5) Heating Oxidation—The temperature rises to 950-1000°C, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| evenness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com