Box-method boron microcrystalline glass source concentrated boron diffusion method

A glass-ceramic and borosilicate glass technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of high surface concentration, long process flow, affecting the series resistance parameters of products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

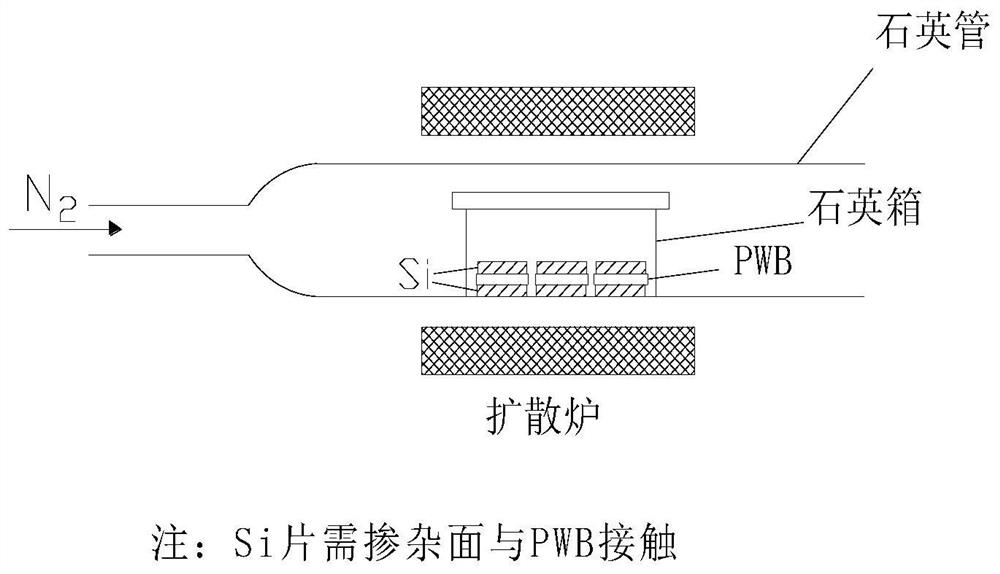

[0050] Box Fault Boron Crystalline Glass Source (PWB) Concentrated boron diffusion technology (constant surface source diffusion), similar to the diffusion of the closed tube, but no seal, different from A S Diffusion needs to be completely sealed.

[0051] The solid-state PWB is used to treat the boron source. Treatment steps: repeatedly wipe the boron source with acetone, then rush, heat, heat, cold ion water, and put it in the infrared light oven to dry the source surface, 30 min However, raise the diffusion furnace to 1100 ° C, and the diffusion furnace 2 The flow rate is 1 l / min, put the PWB source in the quartz boo boat in the quartz box, cover the quartz box, push into the constant temperature zone of the diffusion furnace, and bake over 24 hours or more.

[0052] Boxa Boron Microcrystalline Glass Source (PWB) Concentrated boron diffusion step: raise the diffusion furnace to 1100 ° C, pass N 2 1 l / min, the quartz box equipped with a boron source is pushed into the const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com