System, method and apparatus for spring-energized dynamic sealing assembly

一种密封组件、弹性体的技术,应用在发动机的密封、发动机元件、活塞环等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

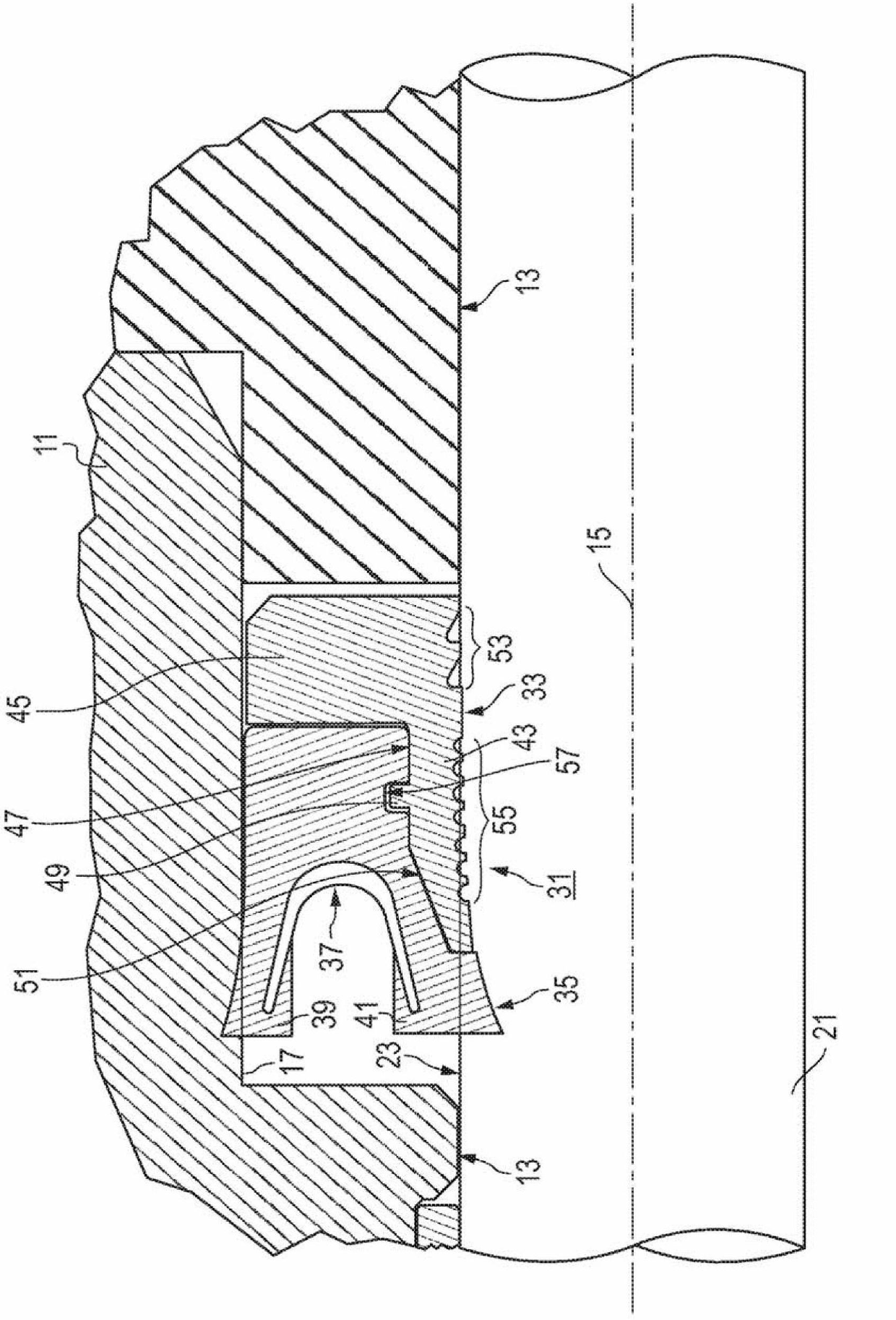

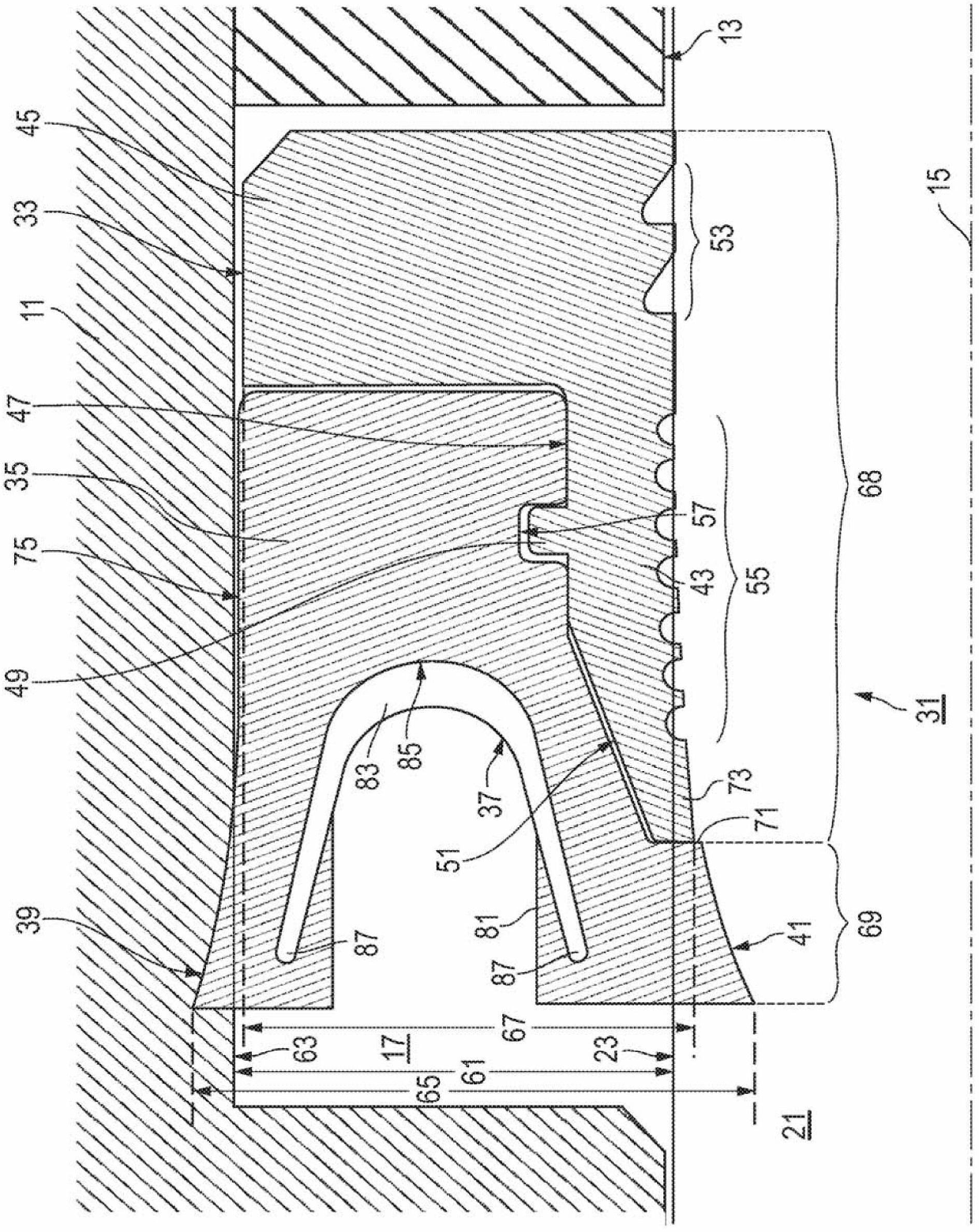

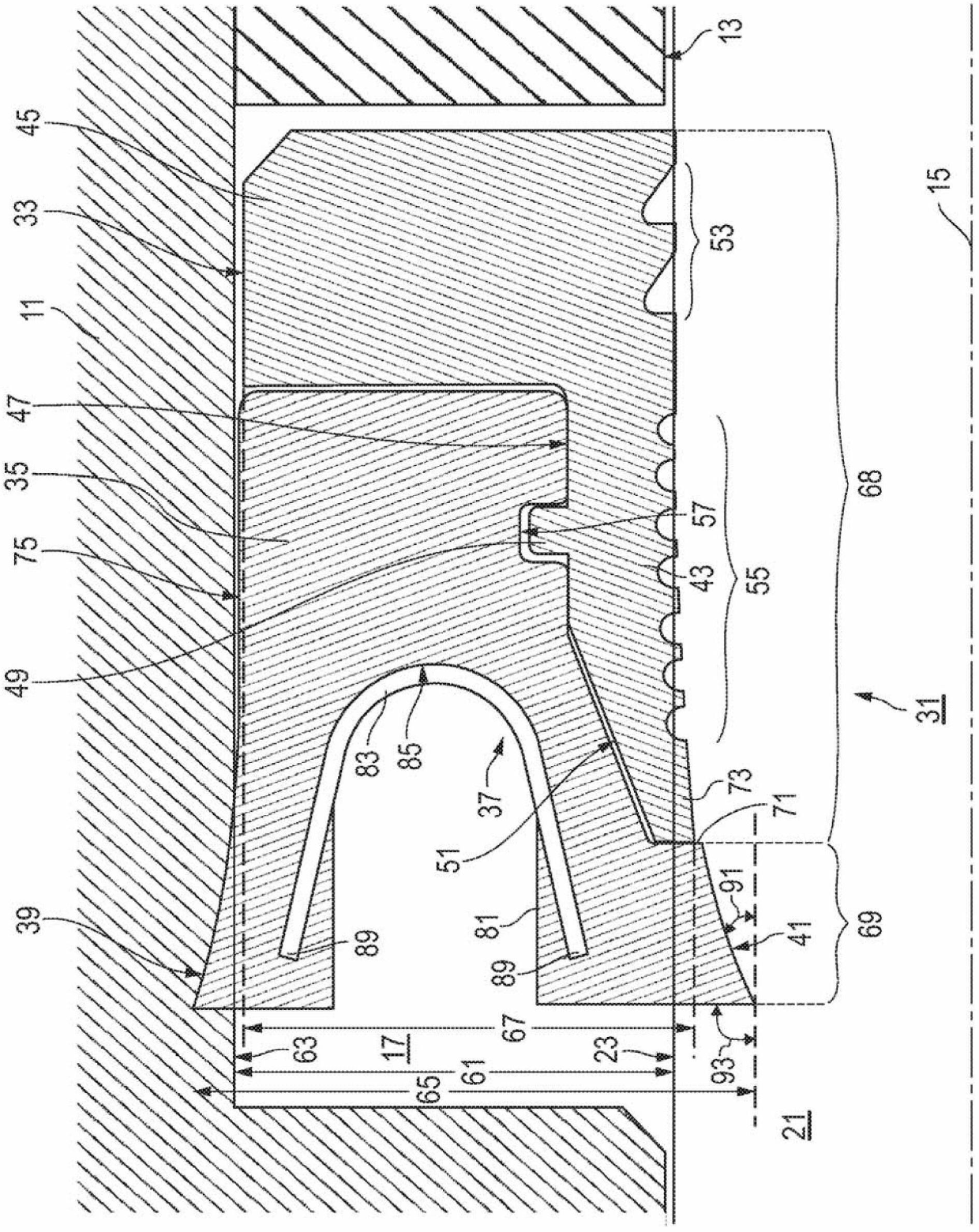

[0015] see Figure 1-7 , disclosing various embodiments of an improved system, method and apparatus for dynamic sealing assemblies, such as for linear motion applications. E.g, figure 1 and 2 An embodiment of a system is disclosed comprising a housing 11 having a bore 13 with an axis 15 and a gland or recess 17 within the bore 13 . A rod 21 is coaxially located in bore 13 for axial movement relative to housing 11 . In the illustrated embodiment, the rod 21 has an outer surface 23 that includes a dynamic surface relative to the bore 13, which has a static surface 63 ( figure 2 ).

[0016] In some embodiments, a seal assembly 31 comprising a radial seal (eg Figure 1-3 and 6) are located in the recess 17 of the hole 13. Seal assembly 31 forms a seal between the housing 11 and rod 21 . In some forms, the seal assembly 31 includes three annular components: a polymeric ring 33, an elastomeric body 35 attached to the polymeric ring 33, and a spring mounted within the elastom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com