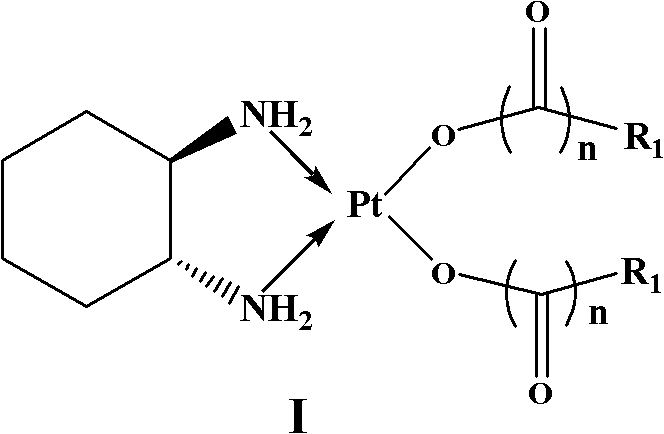

Preparation method for insoluble spherical medical granules

A technology of insoluble drugs and spherical particles, which is applied in the direction of pharmaceutical formulas, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1: the preparation of spherical particle of the present invention and its suspension

[0065] Add 4 g of paclitaxel to 100 ml of dichloromethane, and use a 250W ultrasonic cleaning machine (JCX-250G, Jining City, Shandong Province Ultrasonic Electronic Instrument Factory) to set the power at 100%, set the temperature at 37 ° C, and ultrasonically for 30 min. Dissolves active ingredient. The solution was sterile filtered through a 0.22 μm filter, and the resulting solution was the dispersed phase. Under aseptic conditions, take 2500ml of sterile glycerol for injection as the continuous phase.

[0066] In a 5L stainless steel reactor, a peristaltic pump was used to add the dispersed phase into the continuous phase, and at the same time, a high-shear homogeneous emulsifier (L4RT type, Silverson Company) was used to emulsify at 600 rpm for 3 min to form an emulsion. Under low-speed stirring with mechanical stirring in the reaction kettle, an oil-free chemical d...

Embodiment 2

[0070] Embodiment 2: the preparation of spherical particle of the present invention and suspension thereof

[0071] Add 4 g of paclitaxel into 100 ml of dichloromethane, and dissolve the active ingredient by ultrasonication at 37° C. for 30 min. The solution was sterile filtered through a 0.22 μm filter, and the resulting solution was the dispersed phase. Under aseptic conditions, take 3000ml of sterile glycerol for injection as the continuous phase.

[0072] The two solutions were respectively pressed into a static mixer (RZ-04667-14 Static mixer, Cole Parmer Company) with a peristaltic pump to mix and emulsify. The formed emulsion enters a heatable stirring tank, heats the solution to 35°C under stirring, and keeps stirring for 60 minutes to remove the solvent in the dispersed phase. Under stirring, the solution was transferred to a washing tank filled with 10L water for injection for washing, and the washing liquid was pressed into a collection tube with a 0.45 μm mixed c...

Embodiment 3

[0075] Embodiment 3: the preparation of spherical particle of the present invention and suspension thereof

[0076] Add 4 g of paclitaxel to 100 ml of dichloromethane, and use a 250W ultrasonic cleaning machine (JCX-250G, Jining City, Shandong Province Ultrasonic Electronic Instrument Factory) to set the power at 100%, set the temperature at 37 ° C, and ultrasonically for 30 min. Dissolves active ingredient. The solution was sterile filtered through a 0.22 μm filter, and the resulting solution was the dispersed phase. Take 25g of polyvinyl alcohol and dissolve it in 142g of water for injection. After the solution is sterilized and filtered with a 0.22μm filter membrane, 2333ml of sterile glycerin for injection is added, and stirred to form a continuous phase.

[0077] In a 5L stainless steel reactor, a peristaltic pump was used to add the dispersed phase into the continuous phase, and at the same time, a high-shear homogeneous emulsifier (L4RT type, Silverson Company) was use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com