Coating machine

A coating machine and coating technology, applied in the field of coating machines, can solve problems such as excessive energy consumption, uneven coating thickness, waste of energy, etc., and achieve the effects of maintaining stability, improving quality, and reducing wind energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

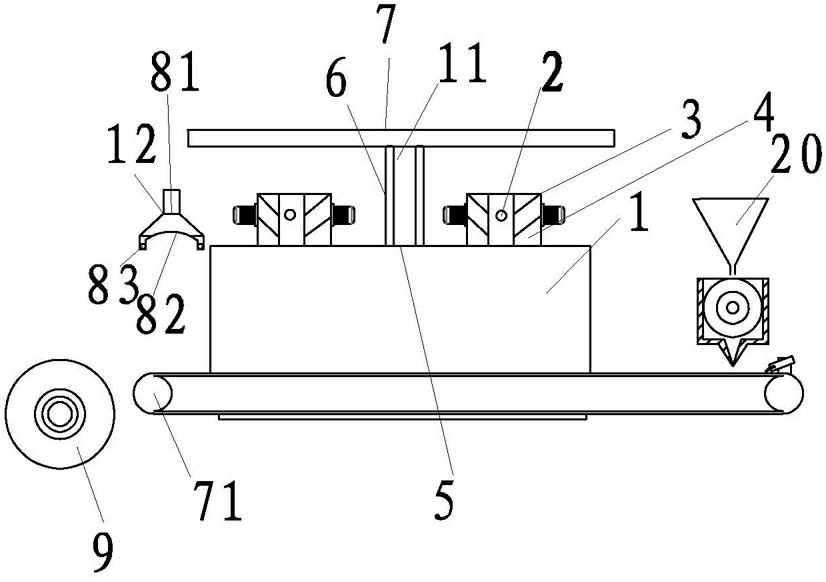

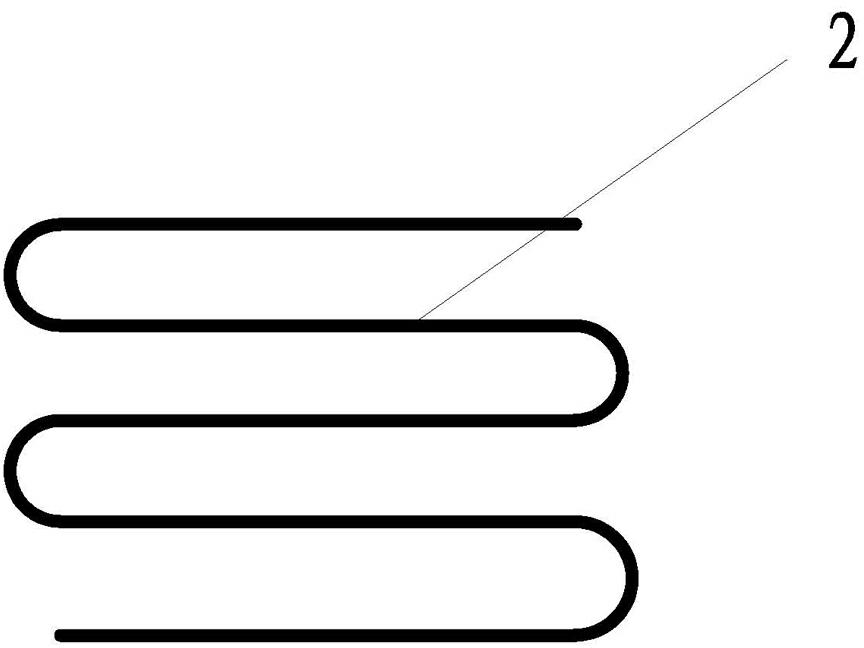

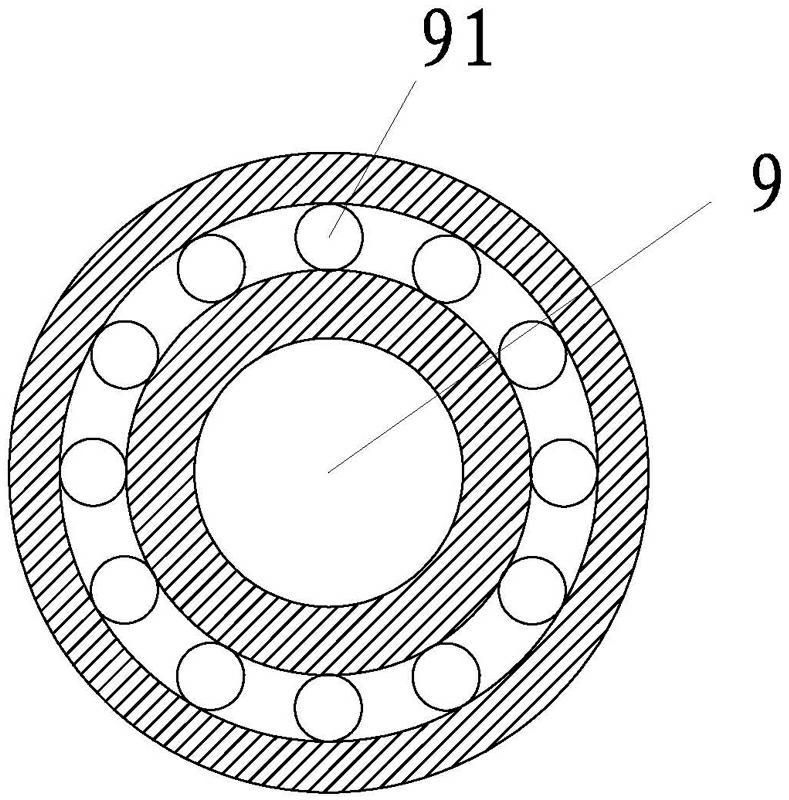

[0019] Example 1, such as figure 1 , 2 , shown in 3, a kind of coater, comprises feeding mechanism, material leading mechanism, coating mechanism, drying mechanism, exhaust mechanism, winding mechanism, and feeding mechanism is connected with coating mechanism by leading material mechanism, and coating structure and The winding mechanism is respectively arranged on the inlet side and the outlet side of the drying mechanism. The drying mechanism is provided with an exhaust mechanism. The drying mechanism is equipped with a transmission roller 71 for transmitting the carrier. Oven 1, a heating pipe 2 is arranged above the interior of the oven 1, and the heating pipe 2 is connected with the heating circulation system arranged outside the coating machine. The heating circulation system is an oil temperature system, and the heating pipe 2 is in the shape of a curve in the oven 1 Setting, two blowing devices 3 are arranged on both sides of the oven 1 close to the heating pipe 2...

Embodiment 2

[0022] Example 2, such as figure 1 , 2 , 3, the difference from Embodiment 1 is that the inclination angle formed between the guiding direction of the two wind direction guiding devices 4 and the horizontal plane is 0°-90°, which can be used in conjunction with the production process of other different products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com