Sectional push boring machining process for camshaft mounting holes

A processing technology and camshaft technology, which is applied in the field of mechanical processing, can solve the problems that the stroke of the machine tool cannot meet the requirements, the installation hole of the camshaft is long, and the intermediate support tool bar cannot be used, so as to solve the problem of difficult machining and ensure the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation

[0022] The technical solutions implemented will be described in detail below in conjunction with the accompanying drawings.

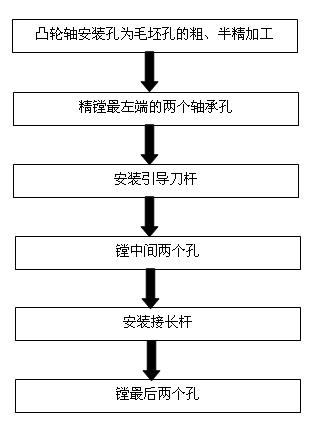

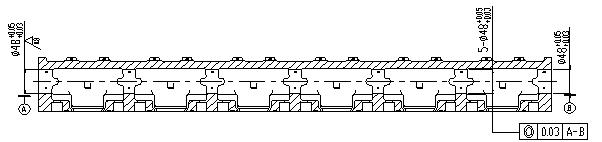

[0023] A machining process for segmented push boring of a camshaft mounting hole, which comprises the following steps:

[0024] ① Rough and semi-finishing where the camshaft mounting hole is a rough hole: The alignment pin holes on the surface of the camshaft support body coincide with the positioning datum during finishing machining, and two holes with the same diameter are bored out at the left and right ends of the camshaft support body. hole;

[0025] ②Finish boring of the two leftmost bearing holes: The positioning of the positioning pin holes on the camshaft support surface in step ① coincides with the positioning datum during finishing, and fine boring of the two leftmost bearing holes;

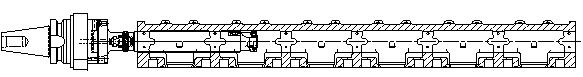

[0026] ③Install the guide tool rod: After boring the two bearing holes in step ②, loosen the tool rod and the tool handle, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com