Method for broaching ultra-deep inner hole of seat tube of cotton-picking head of cotton picker

A processing method and cotton picking head technology, which is applied to metal processing equipment, broaching machines, broaching devices, etc., can solve problems such as inability to lubricate, low roughness, and broken broaches, and achieve high geometric precision and simple process steps , to ensure the effect of smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0013] A method for broaching an ultra-deep inner hole of a seat tube of a cotton picking head of a cotton picking machine, the process steps are as follows:

[0014] (1) The seat tube blank is extruded by an extruder, the length-diameter ratio of the seat tube is 20-60, the diameter of the inner hole of the seat tube is φ27.7±0.1mm, and the coaxiality between the inner hole of the seat tube and the shape of the seat tube is less than 0.1;

[0015] (2) Milling the end face: Use a milling machine to mill the end faces on both sides of the seat tube to ensure that the end face is perpendicular to the center line of the seat tube shape as the reference;

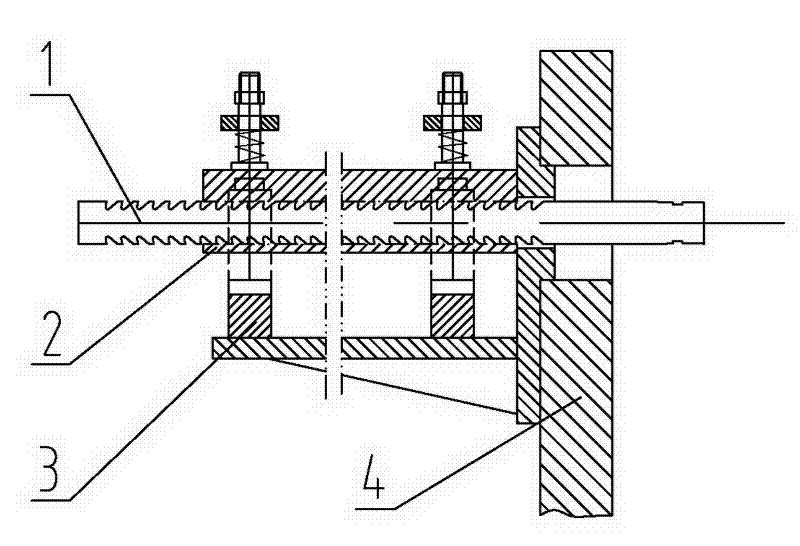

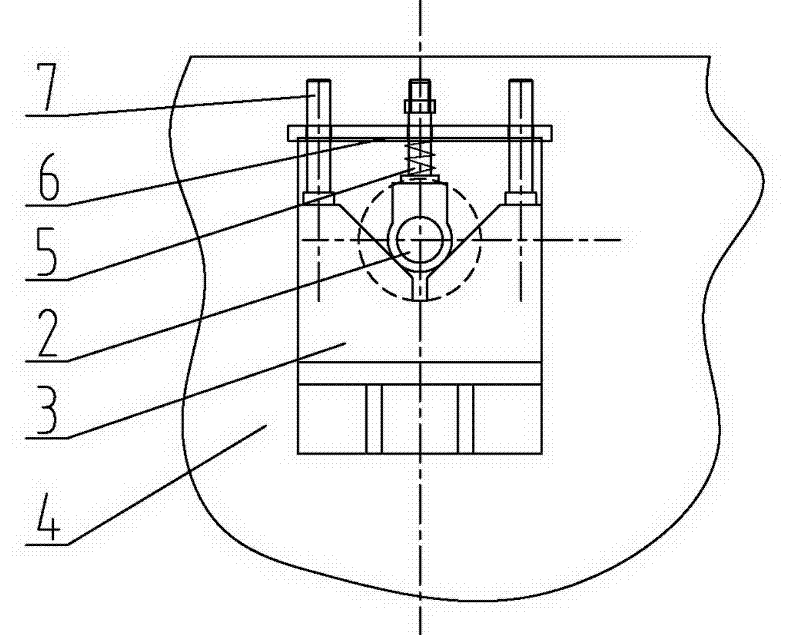

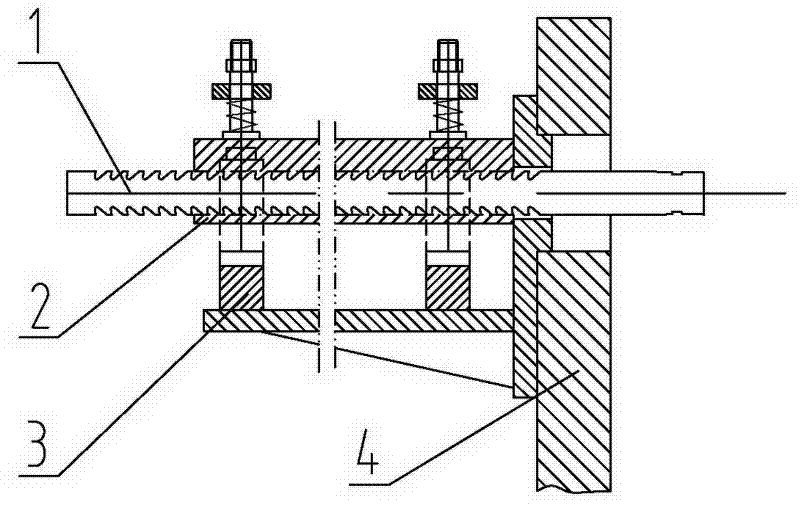

[0016] (3) Broaching: such as figure 1 , figure 2 As shown, a broaching fixture is fixedly installed on the broaching machine 4 of the model L6120. The broaching fixture includes a horizontal base, and a V-shaped positioning seat arranged at an interval is vertically fixed on the front and rear sides of the horizontal base. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap