Light rail output bevel wheel machining process

A processing technology, helical gear technology, applied in the field of light rail output helical gear processing technology, can solve the problems of high design speed, insufficient grinding processing, large output torque of power system, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

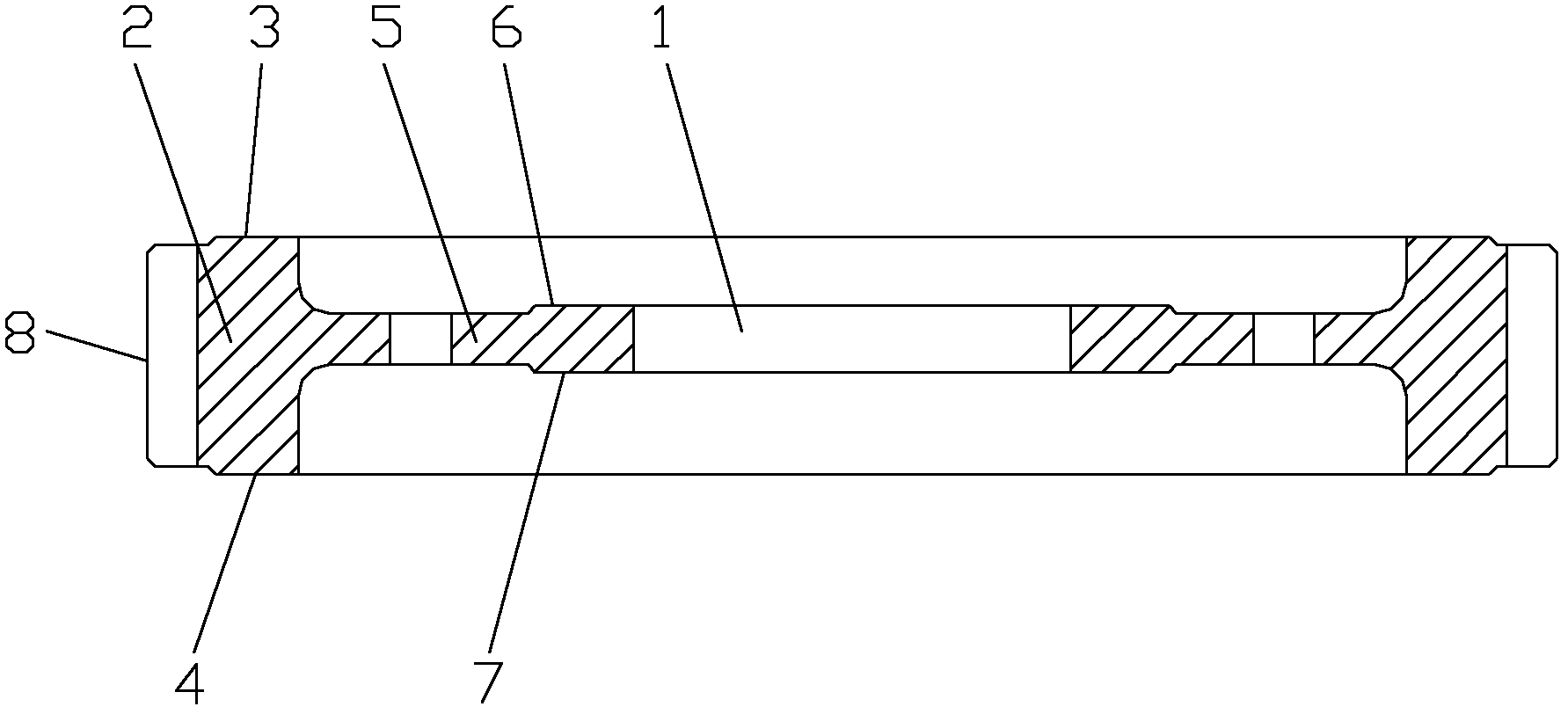

[0029] figure 1 It is a schematic diagram of the structure of the light rail output helical gear. The processing technology of the light rail output helical gear in this embodiment includes blank making, normalizing, semi-finishing, quenching, finishing and final inspection. The blank making includes blank production and tooth blank rough machining The semi-finishing process includes semi-finishing I, semi-finishing II and gear forming; the finishing process includes semi-finishing III, semi-finishing IV, finishing I, finishing II and gear grinding;

[0030] Specifically include the following steps:

[0031] a. Blank making:

[0032] a1. Blank production, using forging or casting to make blanks;

[0033] a2. Rough machining of gear blanks, turning the outer circle, end face, web surface and inner hole 1, leaving 3-5mm machining allowance, and the overall surface roughness reaches Ra6.3;

[0034] b. Normalizing: heat the tooth blank at a temperature between 920 and 950°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com