1342 nanometer wavelength high-power microstructure DFB laser

A DFB laser, laser technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of low yield of dual-mode lasing and single-mode, increase the difficulty and cost of the process, disadvantageous high-power output, etc. Difficulty and cost, effect of increased process difficulty, broad applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

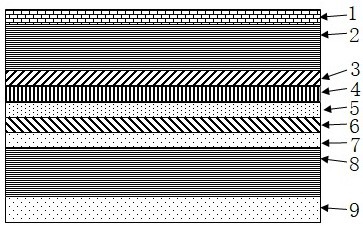

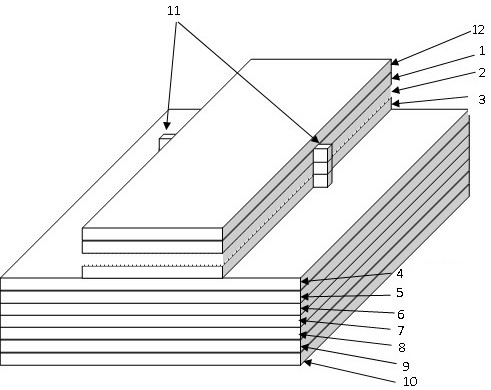

[0048] A high-power microstructure DFB laser with a wavelength of 1342 nanometers, which consists of 11 layer structures and 1 microstructure, which are the lower cover layer 8, the diluted waveguide layer 7, the lower waveguide layer 6, the multi-quantum Well active region 5, upper waveguide layer 4, grating layer 3, upper cover layer 2, contact layer 1, and insulating layer, N electrode 10 covers the bottom surface of the substrate, and P electrode 12 is arranged on the insulating layer and at the ridge strip connected to the contact layer. Such as figure 2 shown.

[0049]The lower cover layer, diluted waveguide layer, lower waveguide layer, multi-quantum well active region, and upper waveguide layer in the epitaxial material constitute stack A, and the grating layer, upper cover layer, and contact layer constitute stack B; and stack...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com