Nitrogen-doped carbon-loaded platinum-based catalyst as well as preparation method and application thereof

A nitrogen-doped carbon and catalyst technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of uneven catalyst morphology, unfavorable catalytic activity and durability, and achieve low cost, improved stability, and reduced platinum The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] For the nitrogen-doped carbon-supported platinum-based catalyst provided in this embodiment, the mass fraction of platinum is 87% based on the mass of the nitrogen-doped carbon-supported platinum-based catalyst as 100%; As 100%, the mass fraction of nitrogen is 6.3%;

[0083] The preparation method of the nitrogen-doped carbon-supported platinum-based catalyst comprises the following steps:

[0084] 1) Weigh 1g of polyacrylonitrile powder into a conical flask, add 5mL of N,N-dimethylformamide, stir in an oil bath at 60°C for 4h until uniform, then pump the polyacrylonitrile solution into the spinning nozzle, set the spinning The distance between the spinning head and the receiver is 20cm, and a high voltage of 15kV is applied between the spinning head and the receiver, and electrospinning is performed under this voltage;

[0085] 2) After 5 h of electrospinning process, the obtained fiber membrane was removed from the receiver and transferred to a tube furnace. In nitr...

Embodiment 2

[0091] For the nitrogen-doped carbon-supported platinum-based catalyst provided in this embodiment, the mass fraction of platinum is 70% based on the mass of the nitrogen-doped carbon-supported platinum-based catalyst as 100%; As 100%, the mass fraction of nitrogen is 8.2%;

[0092] The preparation method of the nitrogen-doped carbon-supported platinum-based catalyst comprises the following steps:

[0093] 1) Weigh 5g of polyvinylpyrrolidone into a conical flask, add 50mL of ethanol, stir in an oil bath at 120°C for 2h, then pump the polyvinylpyrrolidone solution into the spinning nozzle, and set the distance between the spinning nozzle and the receiver to be 20cm, A 20kV high voltage is applied between the spinning head and the receiver, and electrospinning is performed under this voltage;

[0094] 2) After 10 h of electrospinning process, the obtained particle film was removed from the receiver, transferred to a tube furnace, and calcined at a high temperature under the pro...

Embodiment 3

[0098] For the nitrogen-doped carbon-supported platinum-based catalyst provided in this embodiment, the mass fraction of platinum is 60% based on the mass of the nitrogen-doped carbon-supported platinum-based catalyst as 100%; For 100%, the mass fraction of nitrogen is 7%;

[0099] The preparation method of the nitrogen-doped carbon-supported platinum-based catalyst comprises the following steps:

[0100] 1) Weigh 3.5g of polyurethane powder into a conical flask, add 38mL of dimethyl sulfoxide, stir in an oil bath at 100°C for 2h, then pump the polyurethane solution into the spinning nozzle, and set the distance between the spinning nozzle and the receiver to be 20cm, 15kV high voltage is loaded between the spinning head and the receiver, and electrospinning is carried out under this voltage;

[0101] 2) After 8 hours of electrospinning, the obtained particle film was removed from the receiver, transferred to a tube furnace, and calcined at a high temperature under the protec...

PUM

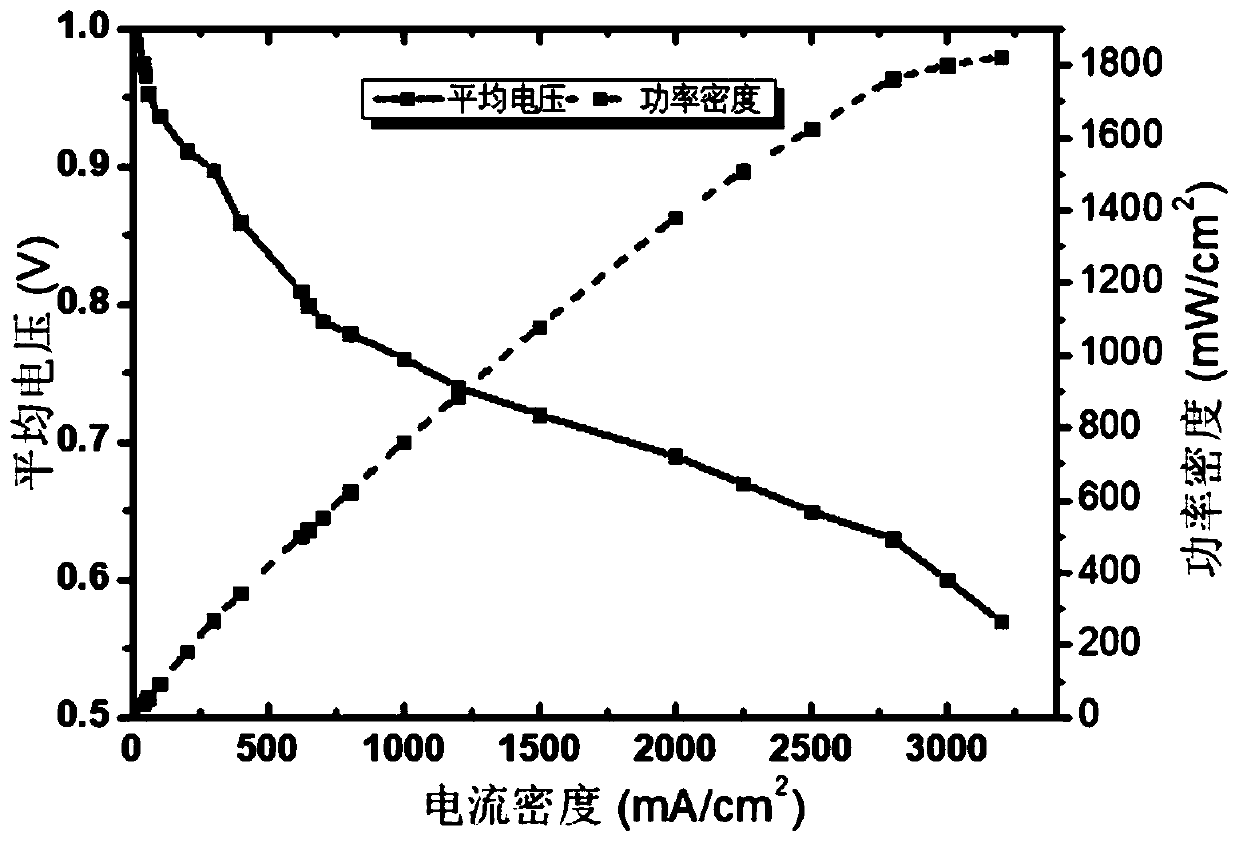

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Peak power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com