Manufacturing method of automatic repair type tire

A technology of automatic repair and production method, applied in the direction of tires, other household appliances, household appliances, etc., to achieve the effect of good sealing performance, strong tire repair ability, and excellent air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention relates to a method for making an automatic repairing tire. According to the conventional method, the automatic tire repairing fire extinguishing liquid is normally filled into the tire to make it an automatic repairing tire.

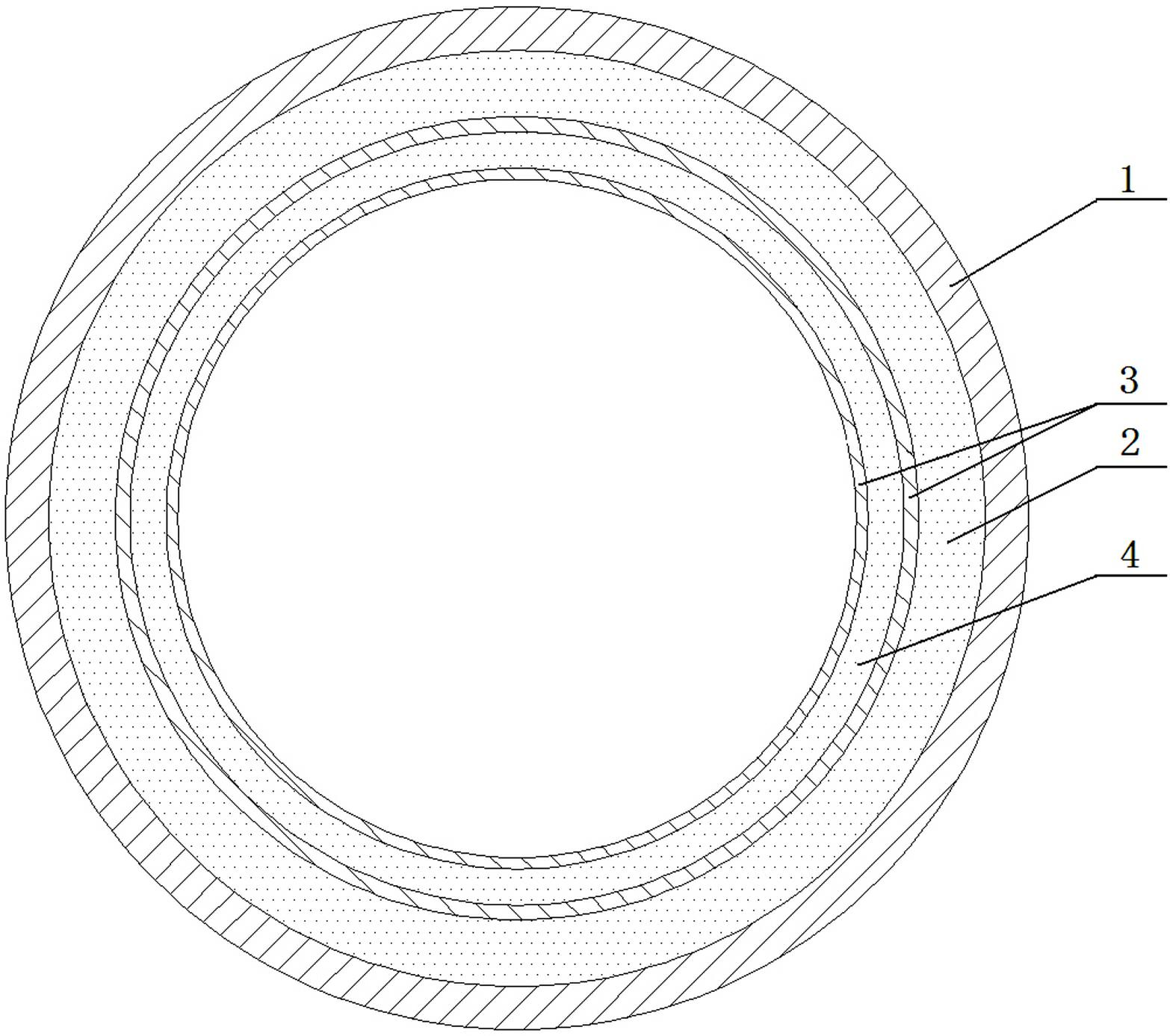

[0017] Such as figure 1 Shown, the tire after the present invention makes is after being filled with the filling layer 2 of automatic inflation tire repair fire extinguishing liquid between the tire cover tire 1 and the inner tube of a tire 3, is filled with the inner filling of automatic inflation tire repair fire extinguishing liquid in the inner tire 3 again Layer 4.

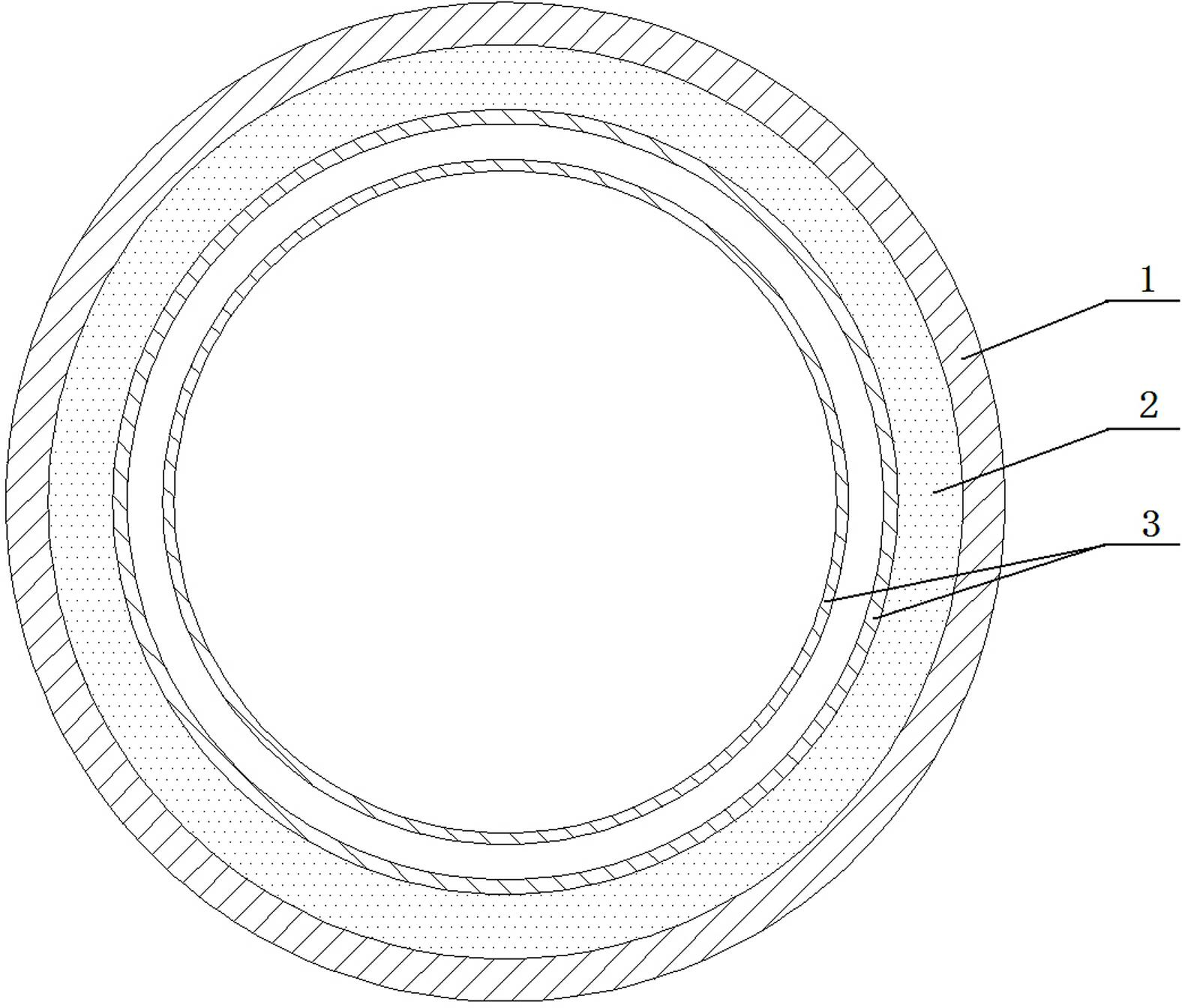

[0018] Such as figure 2 Shown, the tire after the present invention makes is to be filled with the filling layer 2 of automatic inflation tire repair fire extinguishing fluid between the cover tire 1 and the inner tube of a tire 3 of tire.

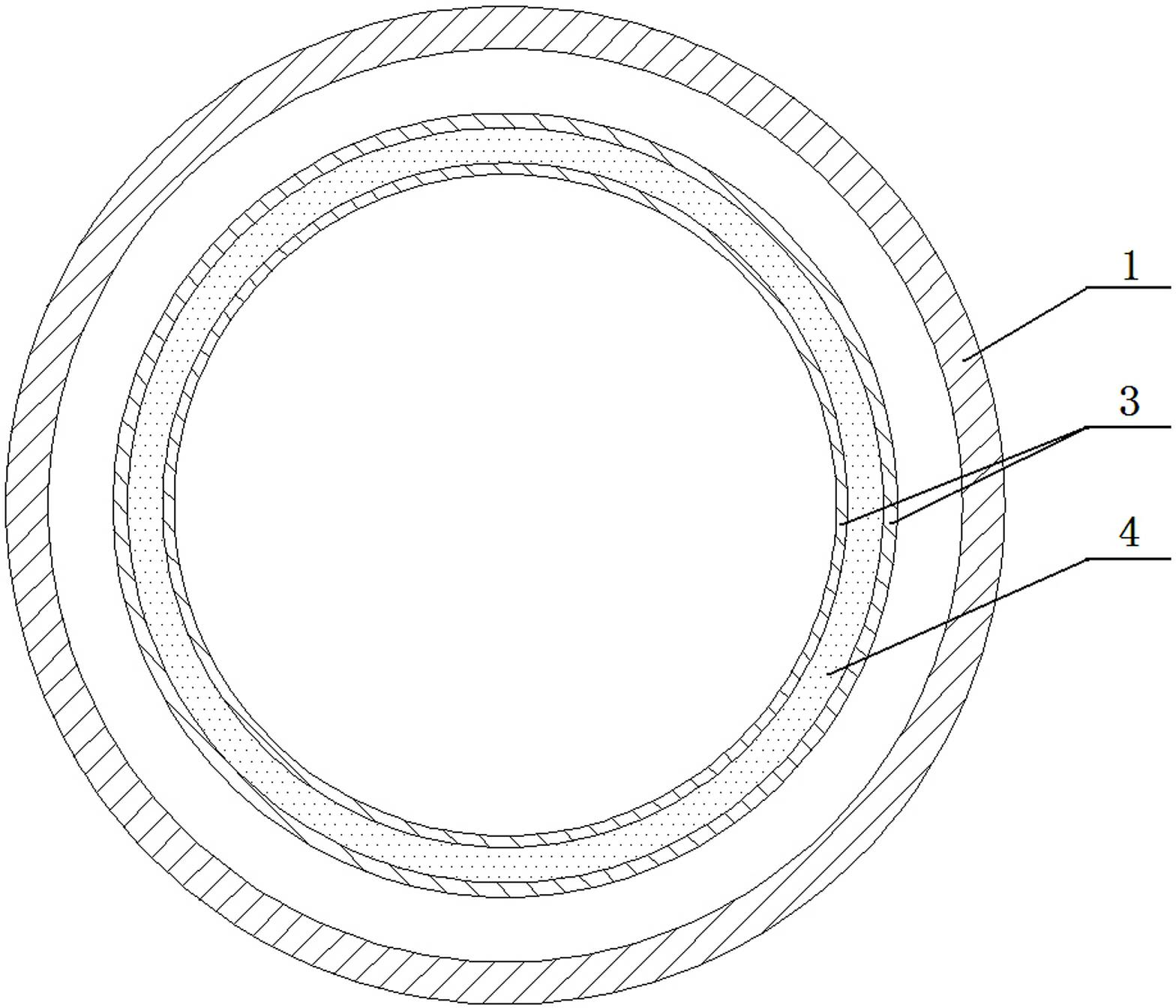

[0019] Such as image 3 Shown, the tire after the present invention makes is only filled with the inner fill layer 4 of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com