Sealing transmission shaft for amphibious vehicle

An amphibious, transmission shaft technology, applied in amphibious vehicles, motor vehicles, transportation and packaging, etc., can solve problems such as failure to meet sealing requirements, water droplets entering the bilge, etc., to achieve the effect of satisfying power transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

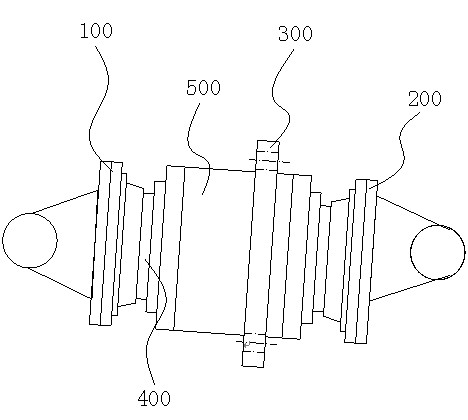

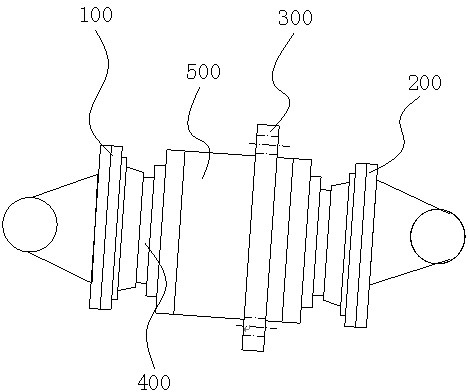

[0012] see figure 1 , a sealed drive shaft for an amphibious vehicle, comprising an inboard flange 100 connected to a drive shaft driven by an engine and an outboard flange 200 connected to drive a front-drive or rear-drive drive system, and also includes a flange connected to the hull The hull flange 300 of the ship, the inboard flange 100 and the outboard flange 200 are connected through a connecting shaft 400 , and the connecting shaft 400 passes through the hull flange 300 . The inboard flange 100 is driven by the engine to rotate, and the inboard flange 100 drives the outboard flange 300 to rotate through the connecting shaft 400, thereby realizing the function of transmission.

[0013] The position where the connecting shaft 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com