Foam pump and liquid distributing ejector with same

A foam pump and liquid technology, applied in the field of foam pumps, can solve the problems of affecting the foaming performance and limited height, and achieve the effects of improving the utilization rate, low cost and fast processing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

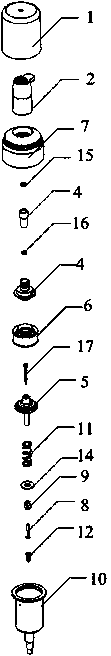

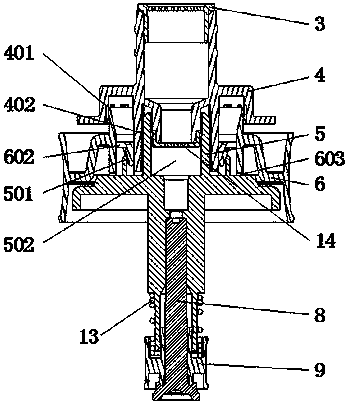

[0064] see figure 1 - Figure 4 , a kind of foam pump, in order to absorb the liquid in the container and make this liquid spray foam from the nozzle, the driving device is a pressure head, the foam former includes one or more screens and a gas-liquid mixing chamber arranged on the discharge channel , the liquid chamber pump unit includes a main column 5, a large piston 6, an upper pressing rod 17, a connecting rod 8, a small piston 9, and a cylinder 10. Including air valve 4, the following examples illustrate.

[0065] The shell is composed of outer cover 1, pressure head 2, screw cap 7 and cylinder 10, and the shell includes pressure head 2, screw cap 7, filter pipe 3, air valve 4, large piston 6, upper pressure rod 17, main column 5, retaining ring 14, small piston 9, connecting rod 8, cylinder 10, spring 11 and valve 12, filter screen pipe 3 is set between pressure head 2 and air valve 4, spring 11 is arranged outside main column 5, wherein:

[0066] A pressure head 2, ...

example 2

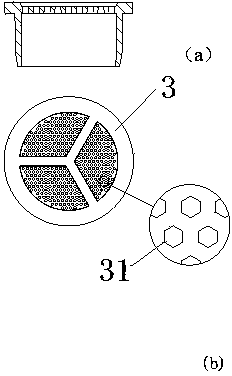

[0080] see again Figure 5 to Figure 8, a kind of foam pump, in order to absorb the liquid in the container and make this liquid eject foam from the nozzle, comprise pressure head, air valve and filter screen support, the nozzle hole is arranged in the pressure head, the air valve is arranged below the nozzle hole, A liquid spray channel is formed between the spray hole and the air valve, and the air valve can be provided with a filter screen support at the inlet and / or outlet of the liquid spray channel, and the filter screen holes on the filter screen support are in the shape of hexagonal holes.

[0081] The air valve is provided at the outlet of the spray channel. The filter screen bracket includes a support ring 32 arranged on the outer wall 41 of the air valve, an inner wall unit 34 and a filter screen unit 33 attached to the inner wall of the air valve, and the support ring 34 is connected to the inner wall unit 34 , the screen unit 33 is located above the inner wall uni...

example 3

[0087] The filter screen support can also be realized by adopting the following structure. see Figure 9A , Figure 9B , Figure 9C , the filter screen support includes an upper end portion 231, a middle block 233 and a lower end portion 232, wherein the upper end portion 231 and the lower end portion 232 are facing in the same direction, and are respectively located above and below the liquid spray channel, and a part of the liquid spray channel is occupied laterally to form a mixed cavity, the middle block 233 is located between the upper end portion 231 and the lower end portion 232, and its setting direction is opposite to that of the upper end portion and the lower end portion, and it is placed in the liquid spray channel laterally, and the part of the liquid spray channel left empty at the upper end is connected to the middle A first channel is formed between the blocks, and a second channel is formed between the part of the liquid spray channel left empty at the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com