Retaining and protecting vehicle for coal mines

A technology for supporting vehicles and mines, which is applied to supporting the roof beams of mine roofs, mining equipment, earthwork drilling and mining, etc. It can solve problems such as death of personnel, inability to realize full mechanization, hidden safety hazards, etc., and achieve simple operation and guaranteed work Safety and reliability, the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

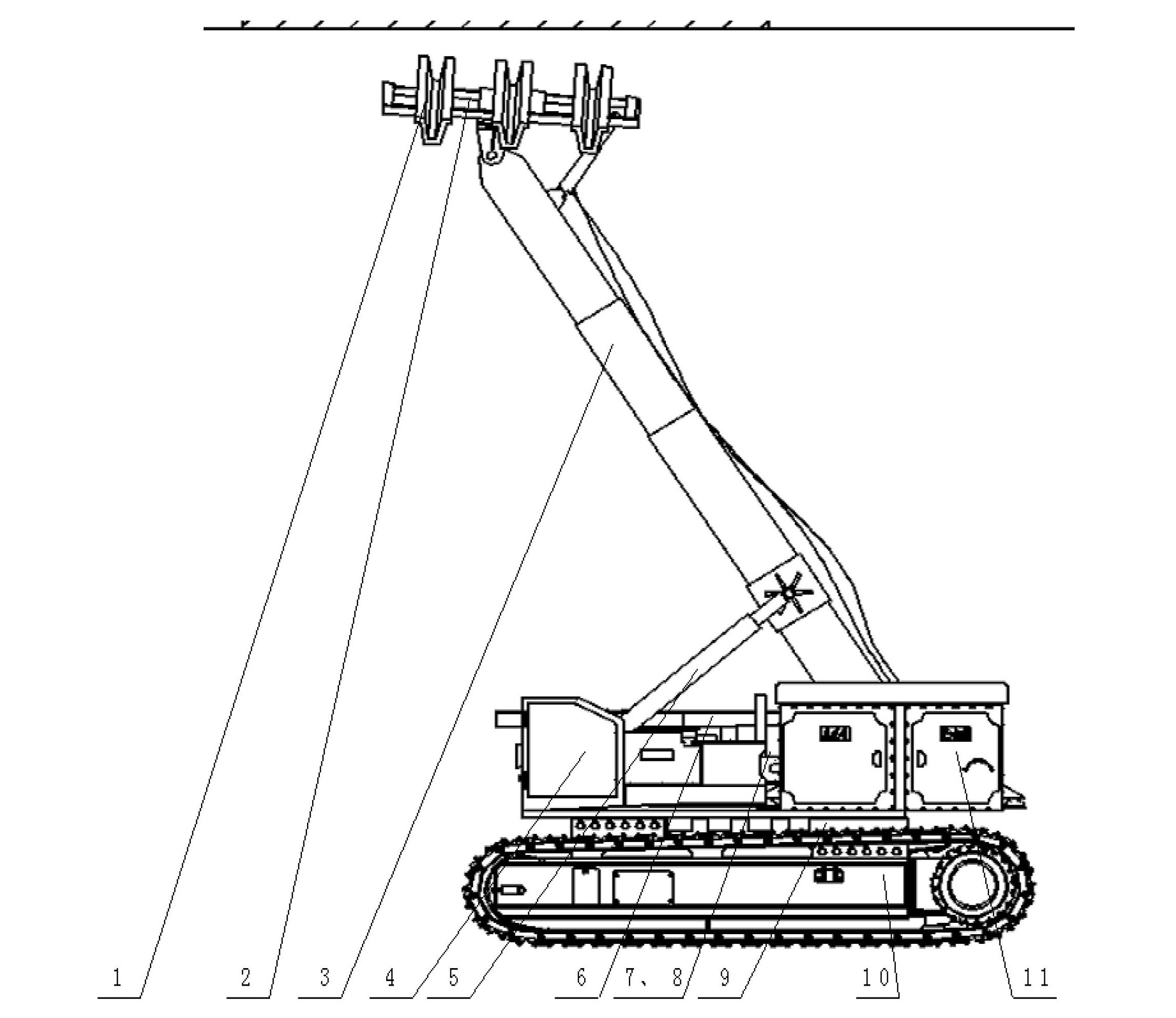

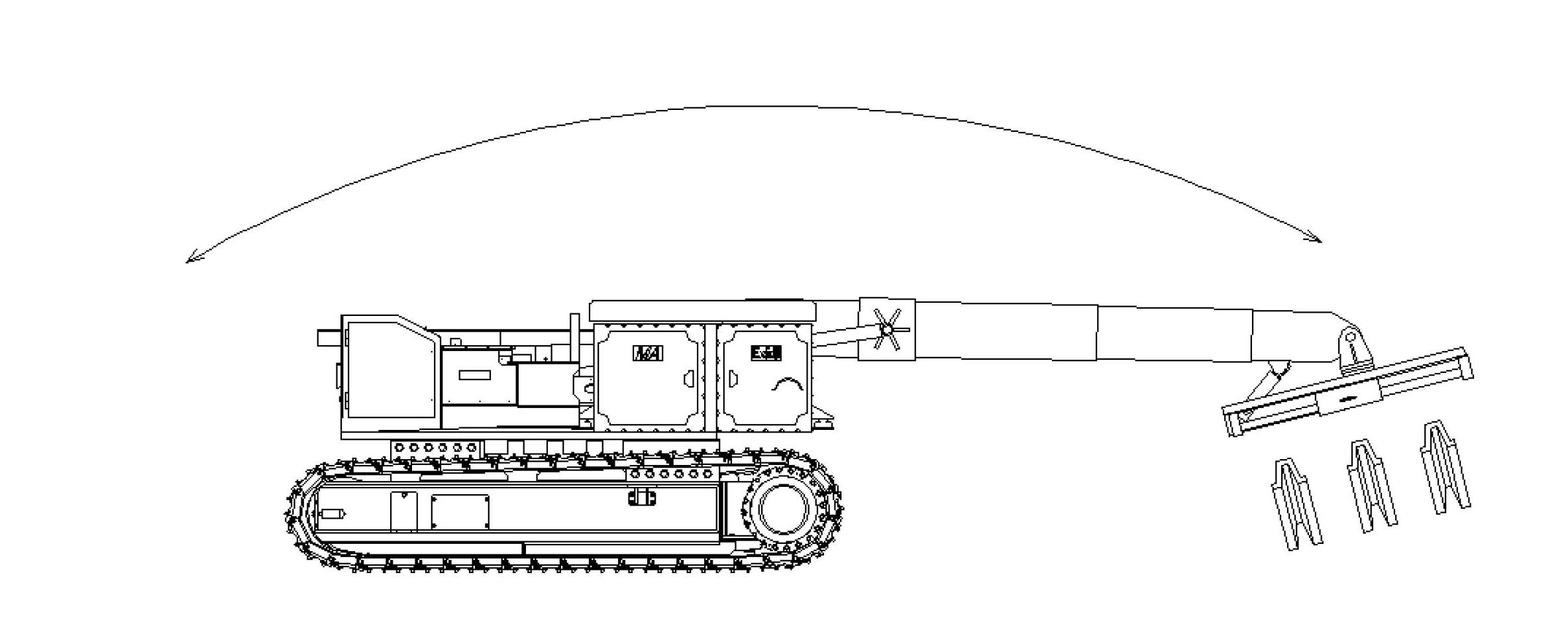

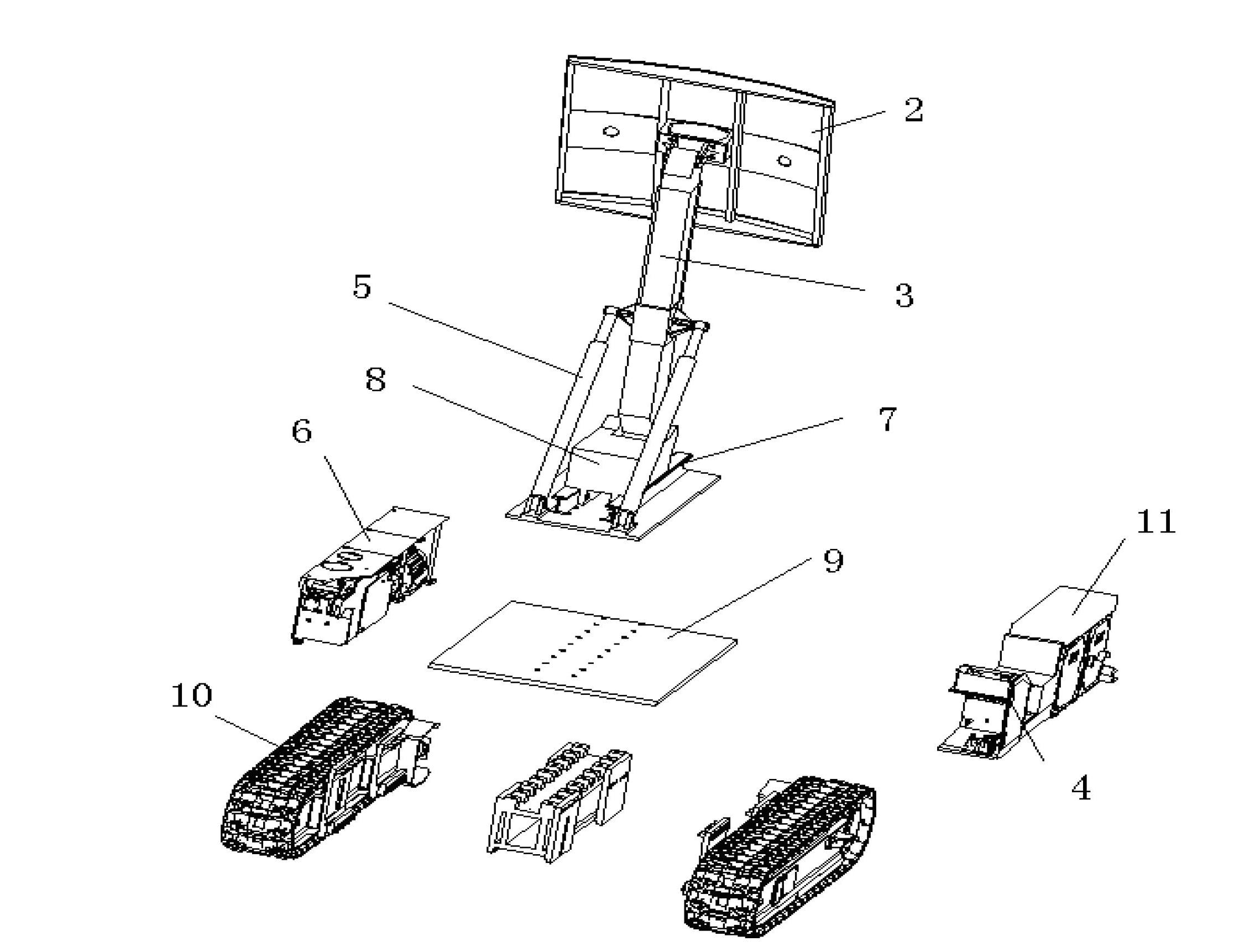

[0013] see figure 1 with image 3 , the complete machine body 9 is installed on the running gear 10, a track 7 is provided on the complete machine body 9, a sliding trolley 8 is provided on the track 7, the lower end of the support arm 3 is hinged on the trolley 8, and the support arm 3 The upper end of the upper end is hinged on the guard plate 2 that can be fixedly installed on the steel beam 1 to be erected. One end of the oil cylinder 5 is hinged to the support arm 3, and the other end is hinged to the complete machine body 9. The complete machine control system 4 is arranged on the left side of the complete machine body 9. At the front end, the machine electrical system 11 is arranged on the left rear end of the complete machine body 9 , and the complete machine pumping station system 6 is arranged on the right side of the complete machin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap