Filling type roller and roller bearing based on same

A roller bearing, filling type technology, applied in shafts and bearings, rotating bearings, bearings, etc., to achieve good structural damping characteristics, ensure bearing capacity, reduce vibration and noise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

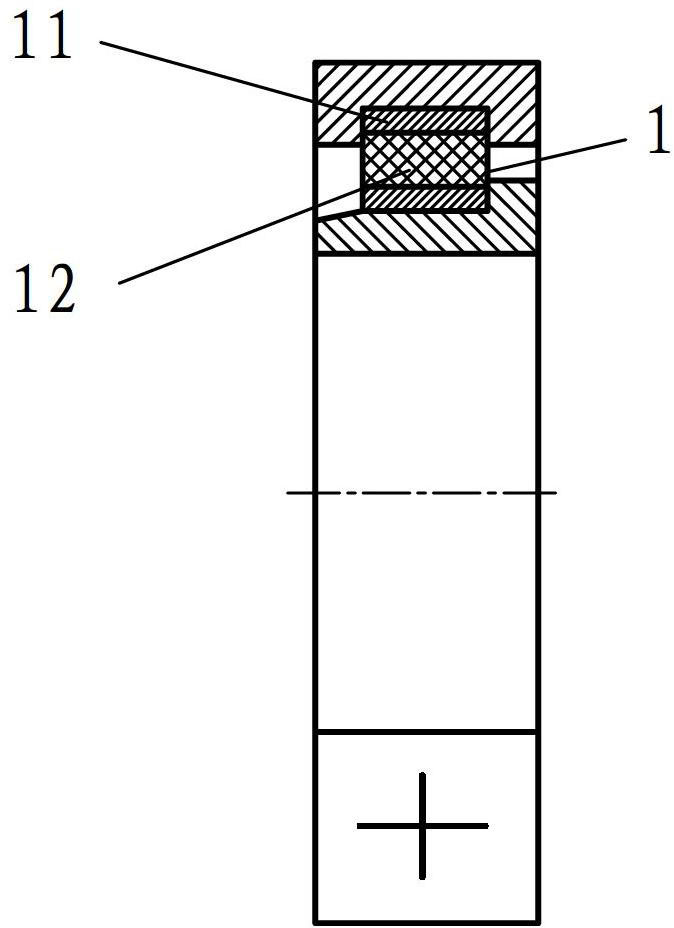

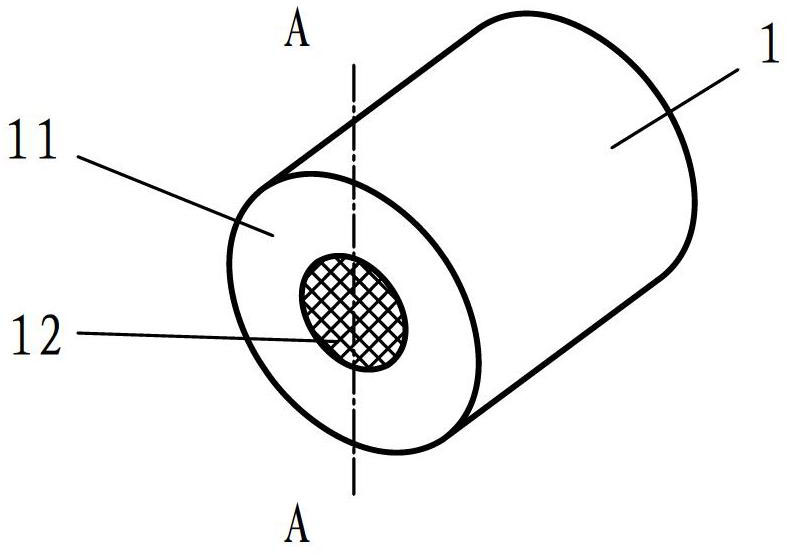

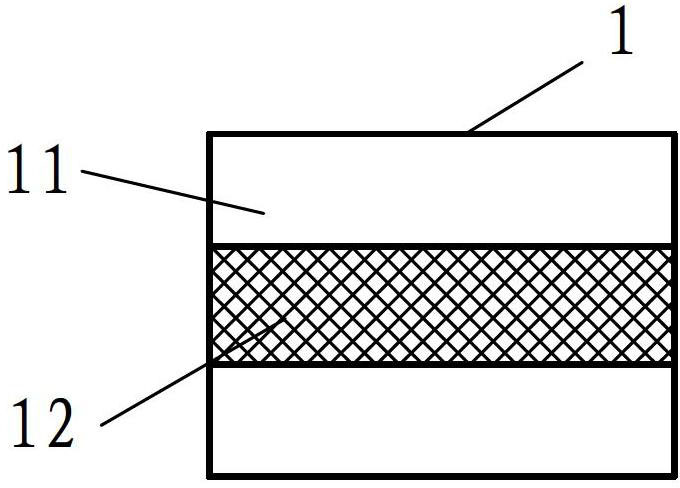

[0016] figure 1 A schematic structural view of the roller bearing of the first embodiment of the present invention is given schematically. Figure 2 to Figure 3 A structural schematic diagram of the roller is further provided. The roller 1 is a cylinder, including a roller outer ring 11 and a roller core 12. The roller outer ring 11 is made of bearing steel, and the roller core 12 is made of methyl vinyl silicone rubber. The roller core 12 is located on Inside the roller outer ring 11. The shape of the roller core 12 is a cylinder with the same central axis as the roller 1 . The roller bearing based on the filled roller thus constituted has good vibration and noise reduction performance.

[0017] Figure 4 Shown is a sectional view taken along the axis of the roller in the second embodiment of the present invention. Compared with the first embodiment, the shape o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap