Damper pulley

A technology of pulleys and rims, applied in the direction of belts/chains/gears, springs/shock absorbers, components with teeth, etc., can solve problems such as heavy weight, restrictions, and complex structures, and achieve good friction resistance and impact resistance Effects of performance, adequate strength and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

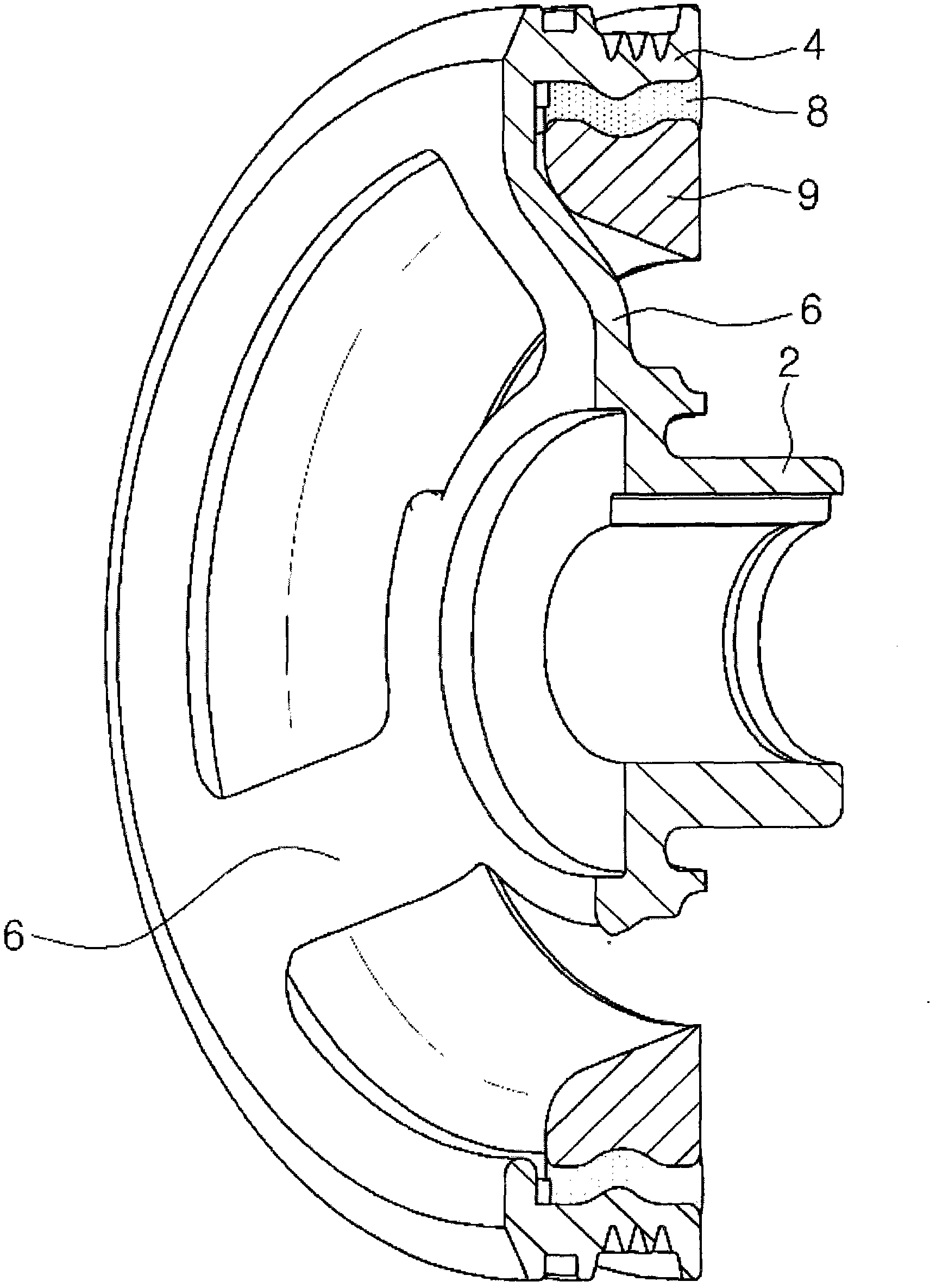

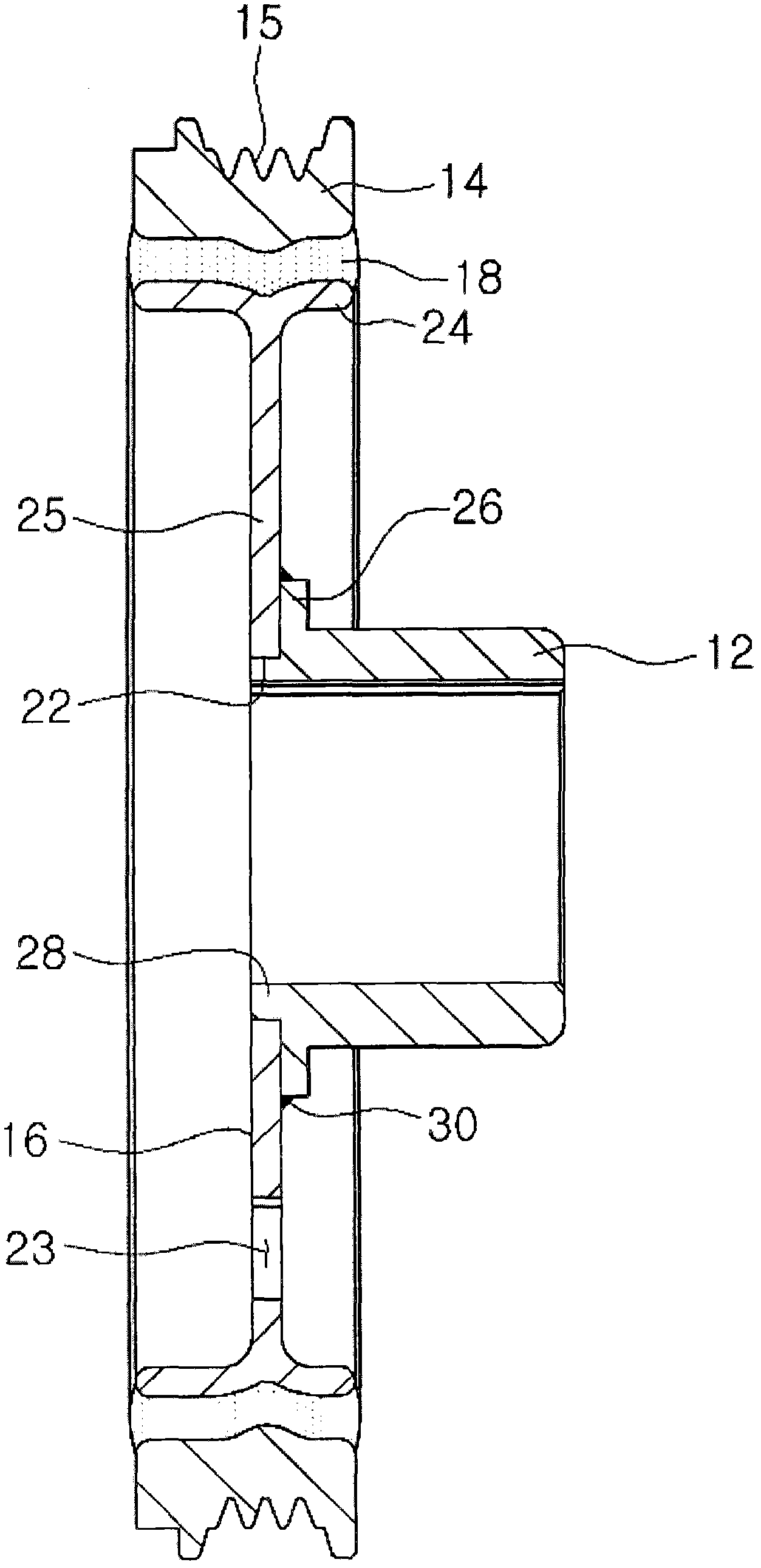

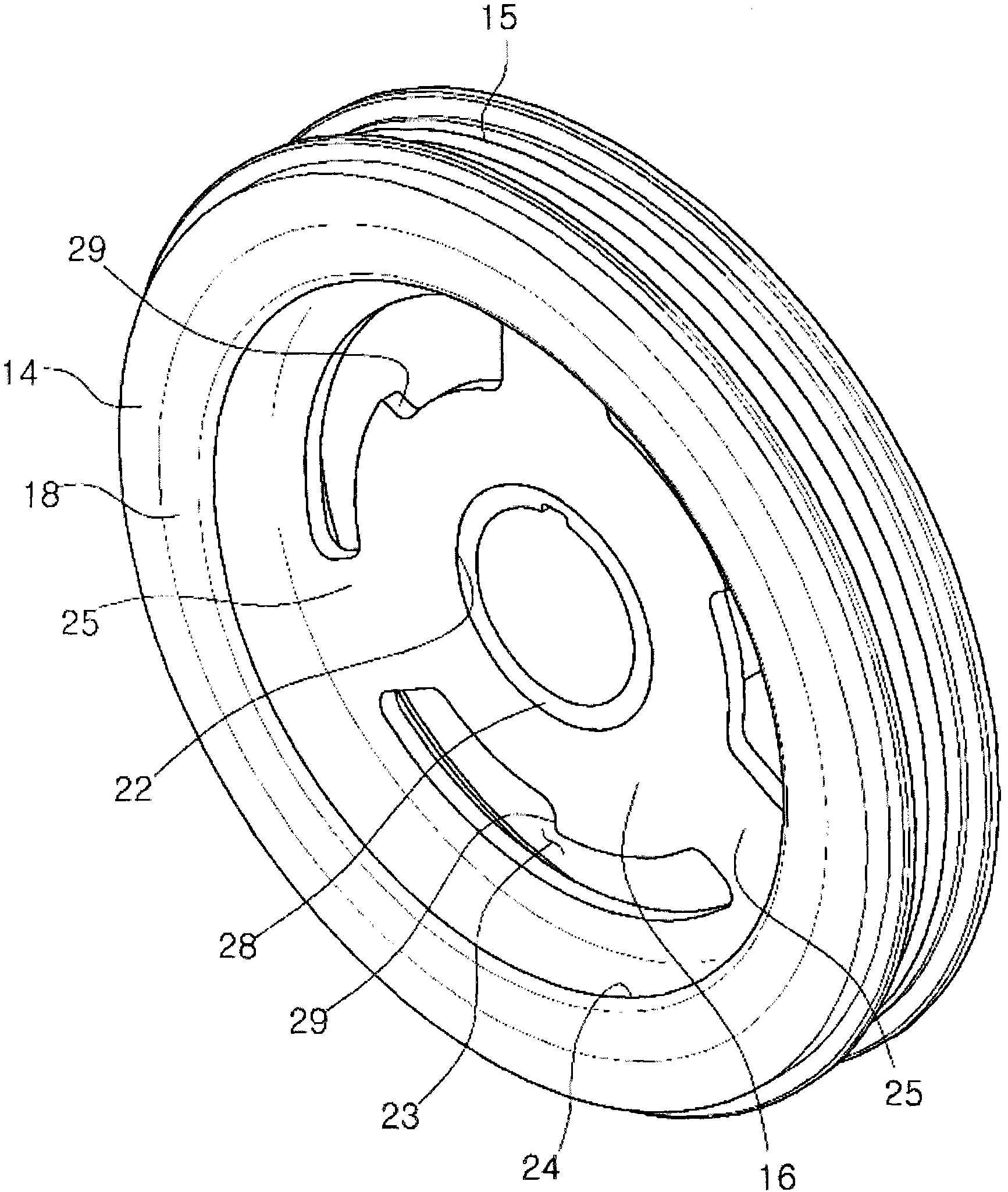

[0015] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings. figure 2 is a cross-sectional view according to an embodiment of the present invention, image 3 and Figure 4 Schematic representations of one side and the other, respectively, of the described embodiment. As shown in the figure, the damping pulley according to the present invention includes: a hub 12, which is cylindrical and combined with a crankshaft; a hub spacer 16, which is combined with a peripheral portion of the hub 12, a central portion of the liner 16 is formed with a through hole 22, and a peripheral portion of the hub liner 16 is formed with a rim 24; a rubber layer 18 attached to the outer peripheral surface of the rim 24 of the hub liner 16; and The pulley 14 is attached to the outer surface of the rubber layer 18 .

[0016] The hub 12 according to the present invention is cylindrical and made of cast iron material, preferably, ductile iron wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com