Single-surface sealed and two-way pressure bearing vacuum gate valve device

A two-way pressure bearing and one-side sealing technology, which is applied in the direction of valve devices, sliding valves, engine components, etc., can solve the problems of many bellows, difficult to realize, and unsatisfactory sealing performance, so as to achieve improved sealing performance and good sealing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

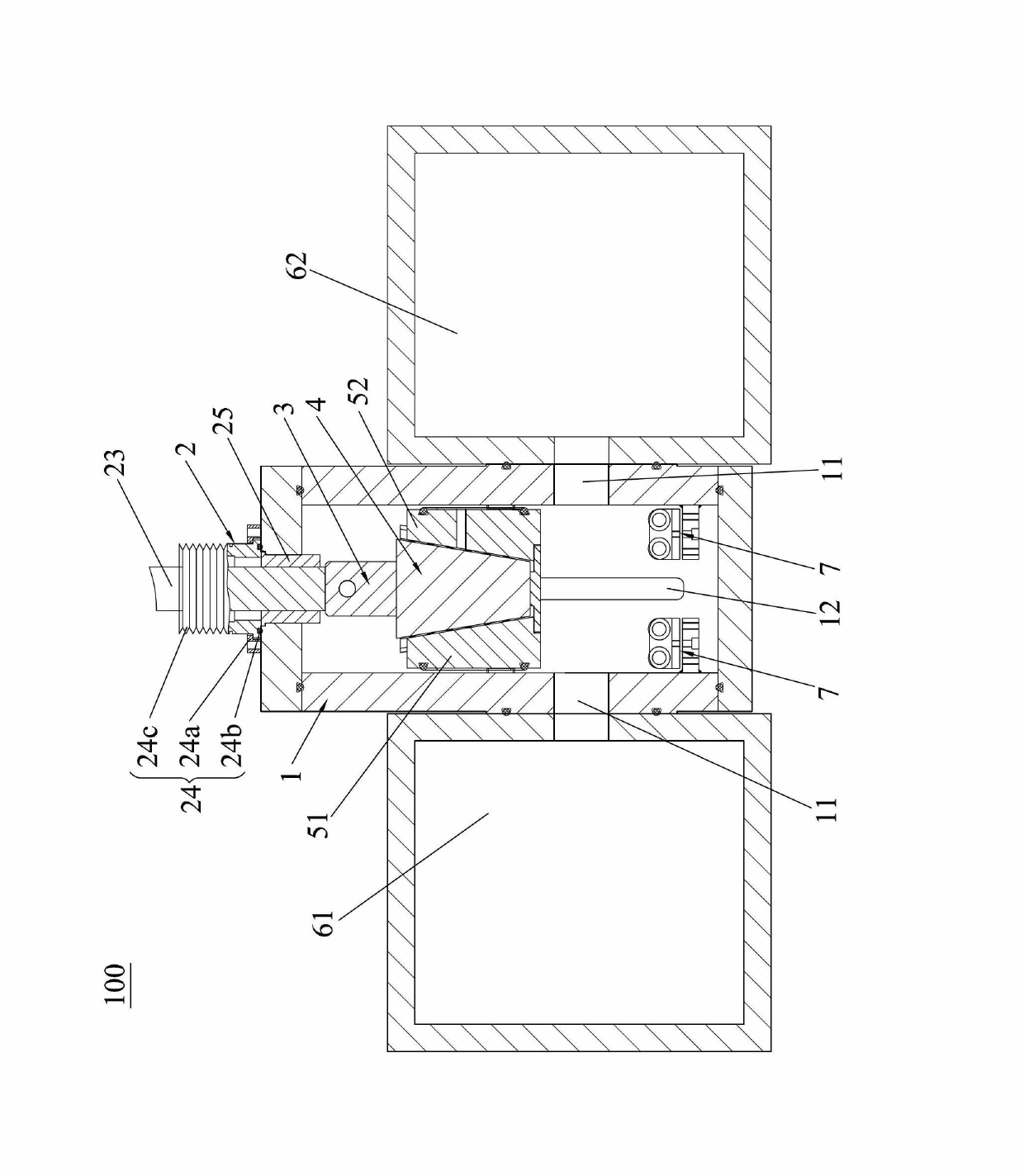

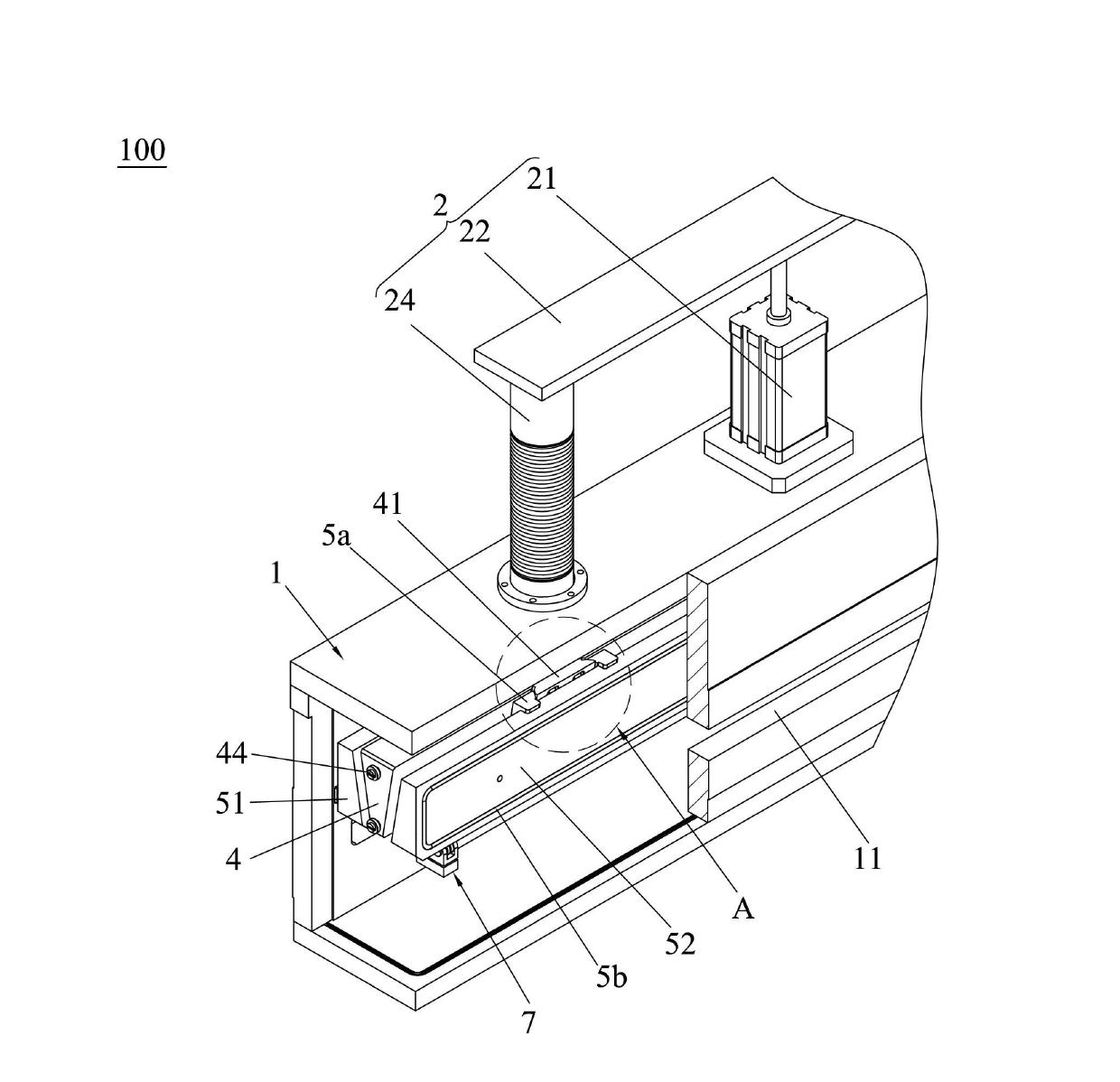

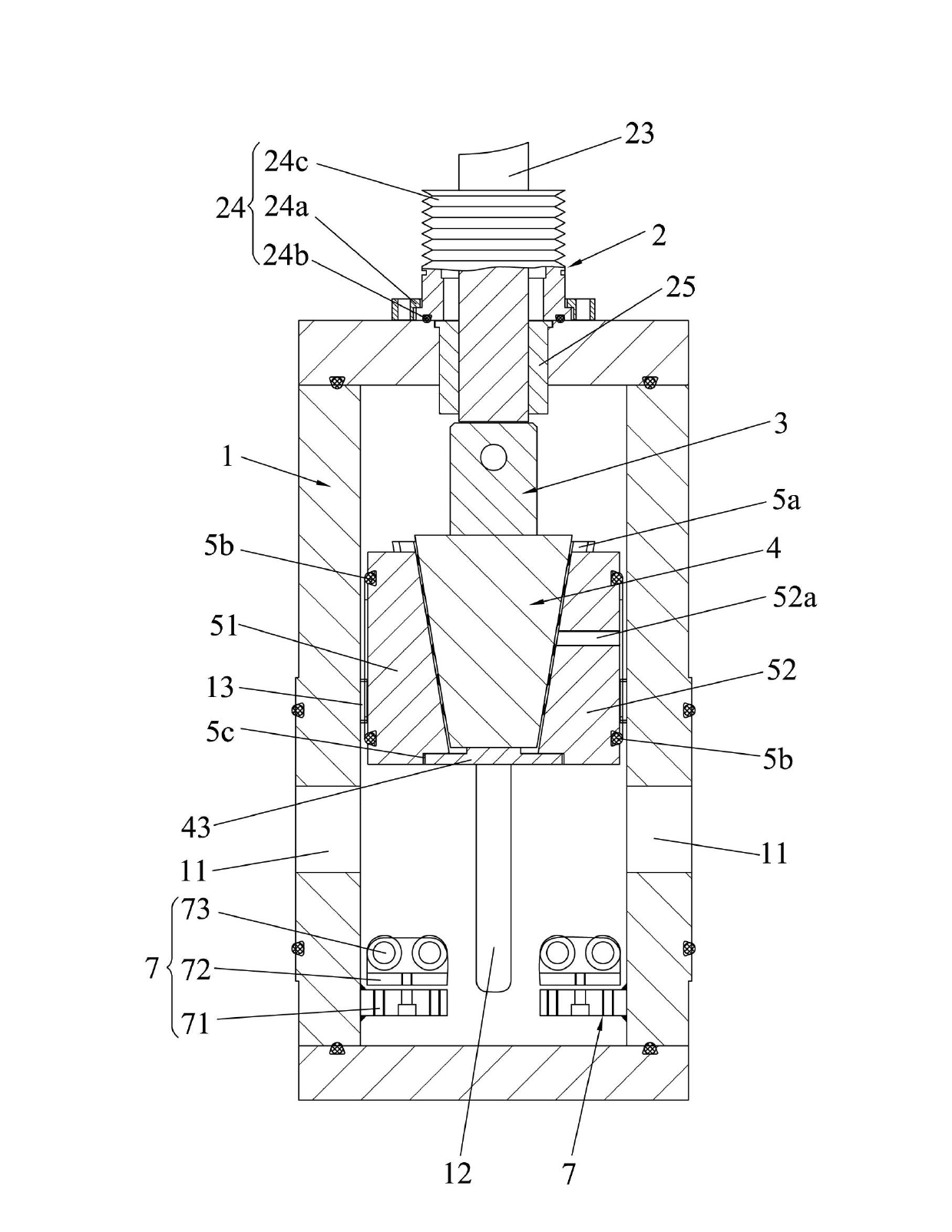

[0026] Such as figure 1 As shown, the single-sided sealed two-way pressure-bearing vacuum gate valve device 100 of the present invention is suitable for the coating or packaging production of solar substrates, and includes a valve body 1 in a hollow structure, a longitudinal driving mechanism 2, a connecting block 3, a wedge 4, a The valve plate is the left valve plate 51 and the right valve plate 52, a pair of vacuum chambers is the left vacuum chamber 61 and the right vacuum chamber 62, and a pair of roller mechanisms 7; the longitudinal drive mechanism 2 is installed on the The upper end of the valve body 1 and the output end are sealingly extended into the valve body 1 and connected with the wedge 4 . The wedge 4, the left valve plate 51, the right valve plate 52, the left vacuum chamber 61, the right vacuum chamber 62 and the roller mechanism 7 are all installed inside the valve body 1; There are openings 11 communicating with each other. The left and right vacuum chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com