Multi-ash biomass energy granular fuel combustor

A technology of biomass energy and granular fuel, which is applied in the direction of combustion method, combustion equipment, fuel supply, etc., can solve the problems of incomplete combustion, insufficient use of heat energy, and failure of thermal energy equipment to work normally, so as to achieve automatic continuous combustion and solve multiple problems. The effect of ash biomass coking and slagging and ash and slagging problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

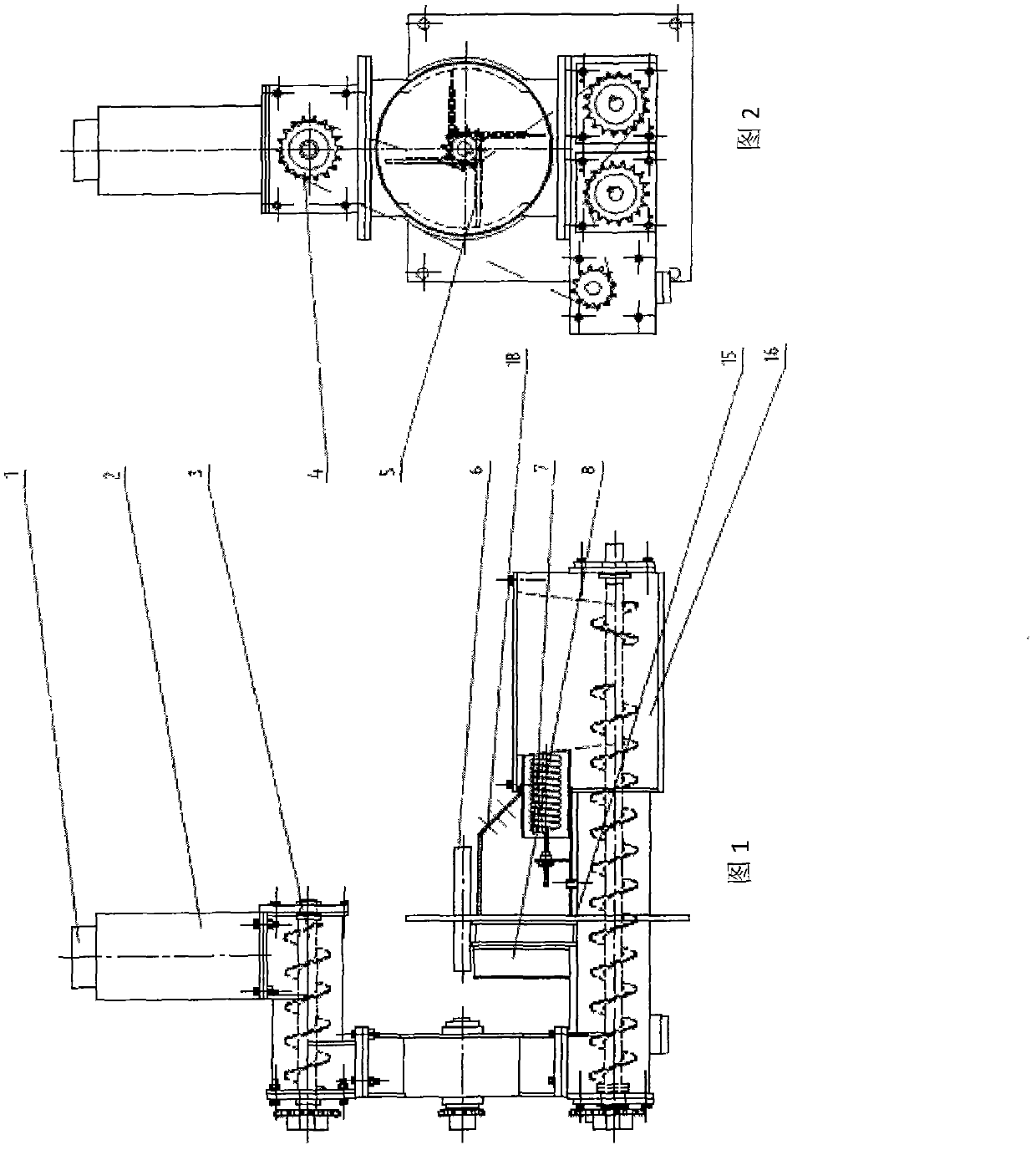

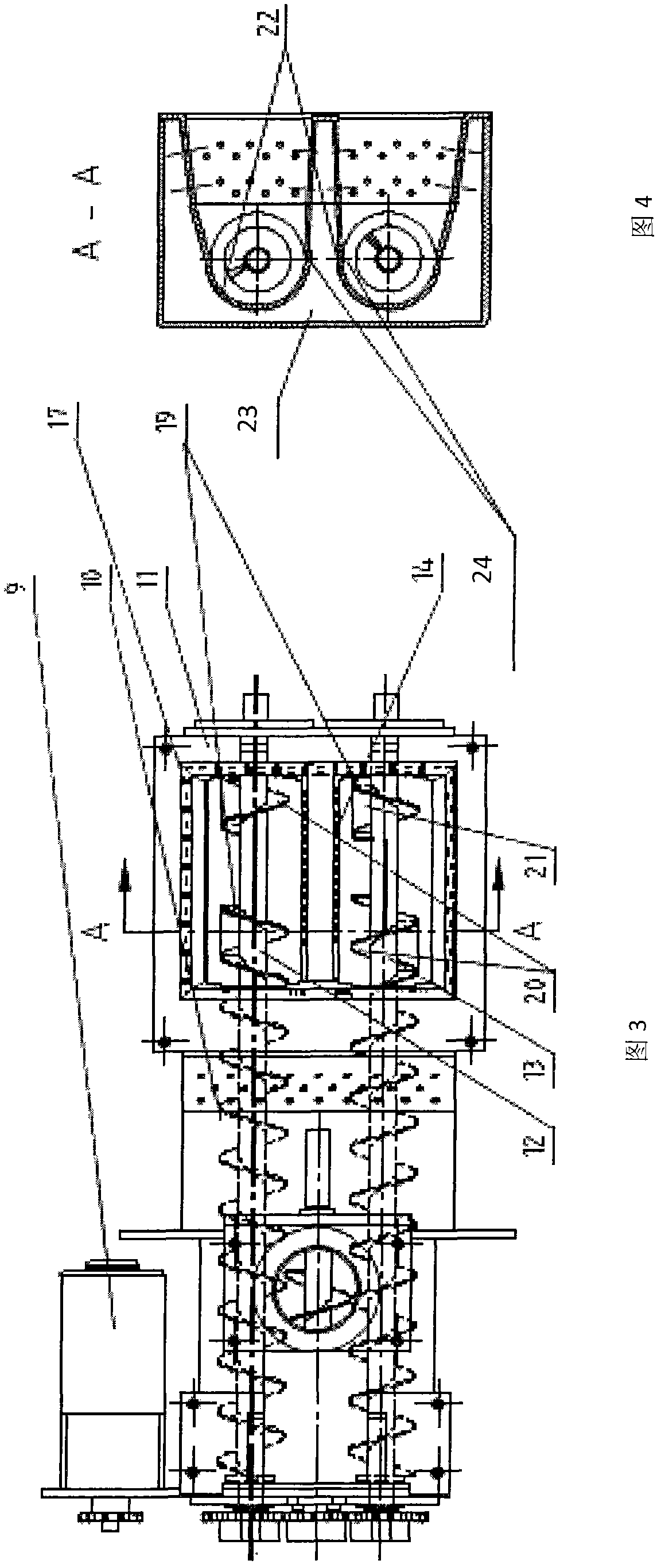

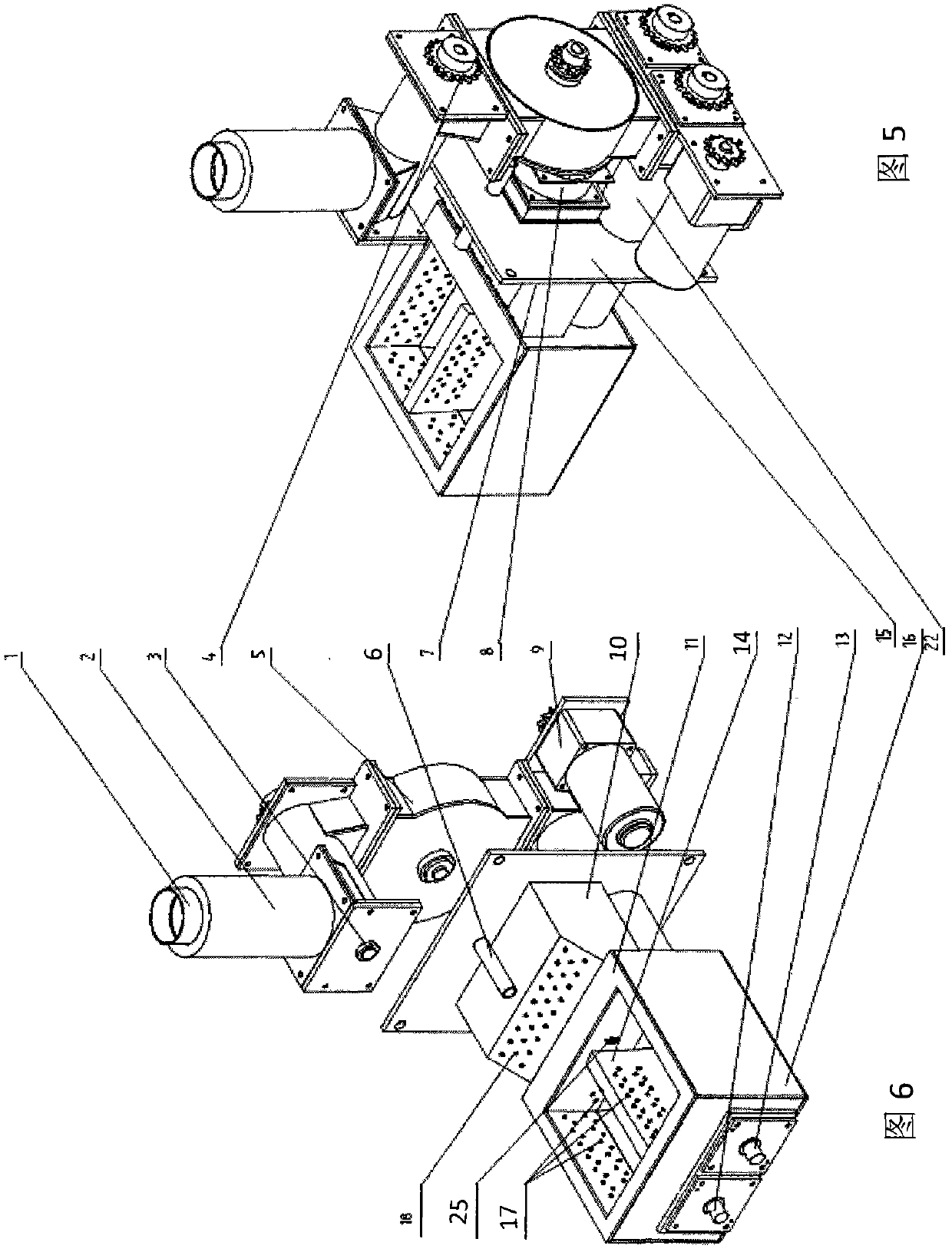

[0039] Like numbers in the drawings indicate like parts.

[0040] like Figure 1-3 As shown, the multi-ash biomass particle fuel burner includes a storage chamber 2, a distributor 5, an air box 14, and a combustion cup 11, wherein the storage chamber 2 has a feed inlet 1, and is connected with the distributor 5 Connected, the granular fuel flowing out from the outlet of the distributor 5 enters the combustion cup 11 for combustion through the feeder circular tube 22 where the left and right auger feeders are placed.

[0041] specific as Figure 4 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 14 , Figure 15 , Figure 16 and Figure 17 As shown, the combustion cup 11 is a large and small bucket-shaped cavity, the top of the cavity is open, and a bellows 14 is housed in the middle of the cavity. The bellows 14 is a trapezoidal cavity with a small top and a big bottom, with the upper part closed and the lower part open. Primary air holes 17 are distributed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com