Compound connecting structure for tube plate and external glass lining tube

A connection structure, glass-lined technology, applied in heat exchanger shells, lighting and heating equipment, sustainable manufacturing/processing, etc., can solve the problems of short service life, blank use, easy leakage, etc., to reduce equipment investment and improve Production capacity and the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

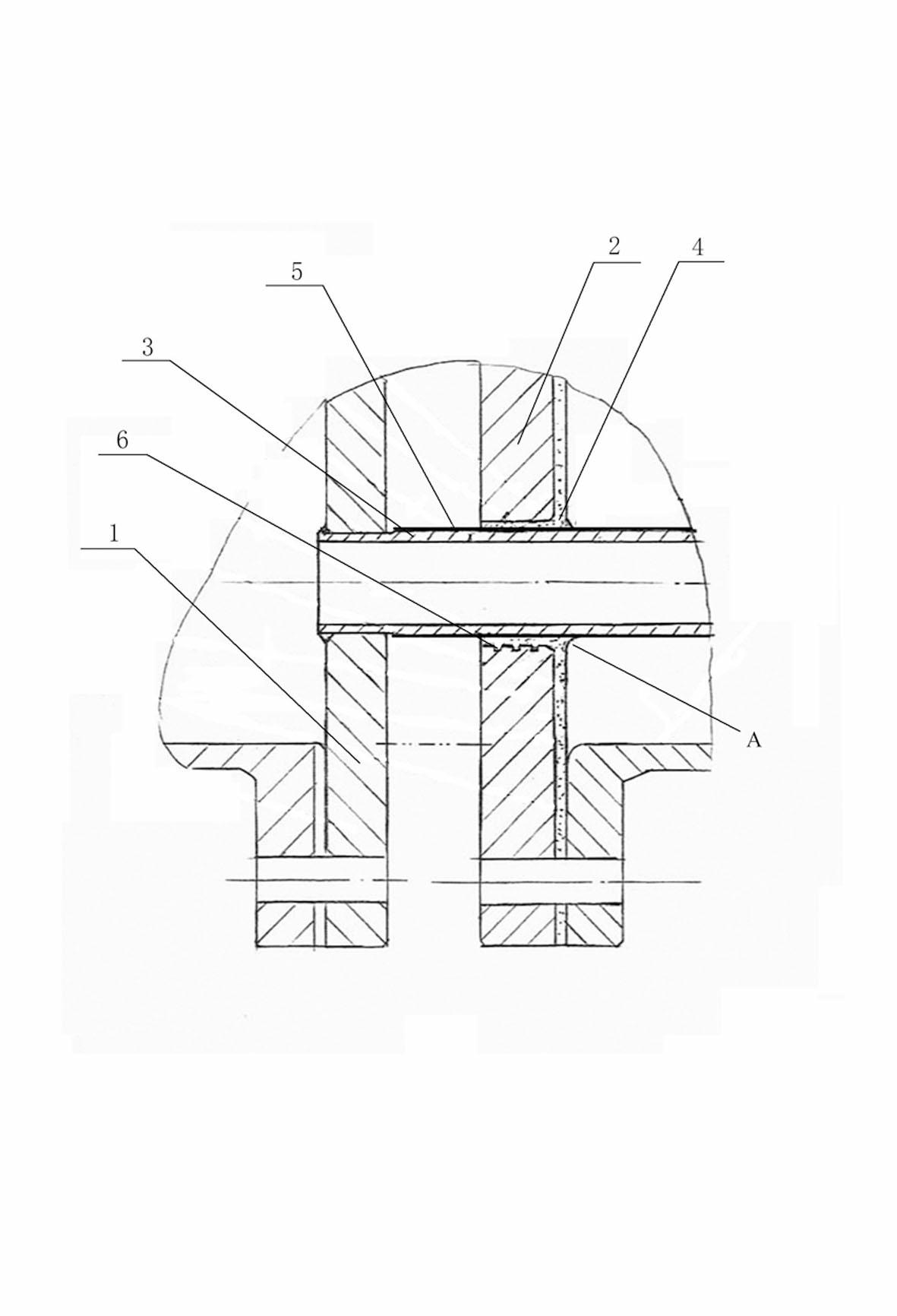

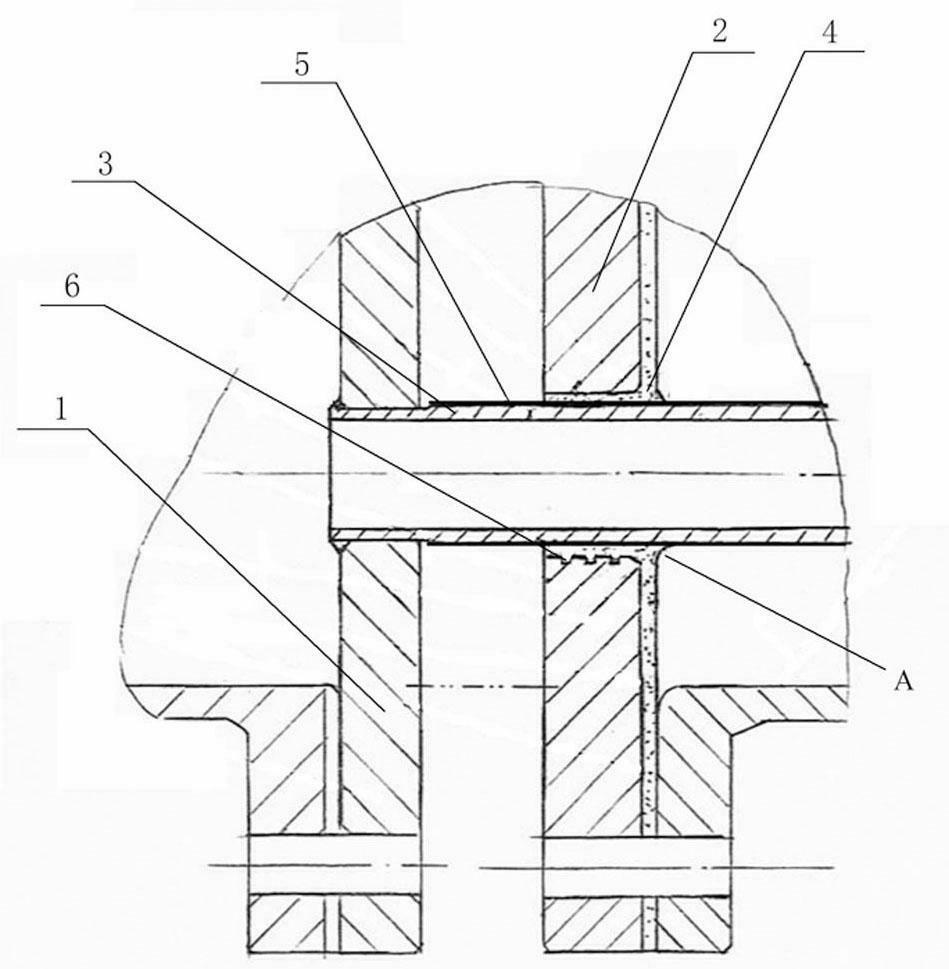

[0015] As shown in the figure, the present invention is mainly composed of outer tube plate 1, bottom plate 2, heat exchange tube 3, protective layer 4, glass-lined layer 5, structural groove 6 and other components.

[0016] The composite connection structure of the tube plate and the outer glass-lined tube includes the outer tube plate 1, the bottom plate 2 and the heat exchange tube 3, the outer tube plate 1 is provided with a first mounting hole, and the bottom plate 2 is provided with a second mounting hole, The left end of the heat exchange tube 3 is inserted into the first installation hole of the outer tube plate 1, and the position of the left end of the first installation hole welds the heat exchange tube 3 and the outer tube plate 1 together, and the heat exchange tube on the right side of the outer tube plate 1 3 is inserted into the second mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com