Firecracker pouring leading line technology method

A process method, firecracker injection technology, applied in pyrotechnics, offensive equipment, weapon types, etc., to achieve the effects of improving insertion quality, reducing material loss and waste, and reducing insertion procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

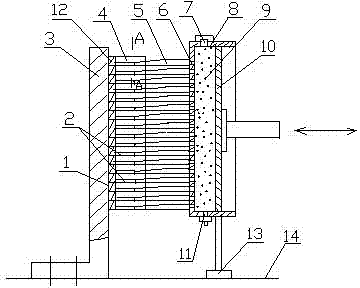

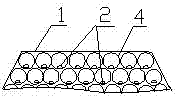

[0011] exist figure 1 and figure 2 Among them, the firecracker cakes 1 arranged in a regular hexagon are horizontally and vertically fixed on the template 3, and an injection device is arranged opposite to the axial direction of the firecracker cake. Extrusion plate 10 for extruding wire paste from injection needle 5, lead paste 9 is installed in the slurry storage chamber, and a slurry filling port 7 (closed when the pressing plate is working) is arranged on the slurry storage chamber, which is convenient for adding lead paste , the bottom of the slurry storage chamber is provided with a cleaning hole 11, which is convenient for cleaning the residual lead slurry in the slurry storage chamber and cleaning the slurry storage chamber. The slurry storage chamber is provided with injection needles 5, the number and arrangement of the injection needles are the same as those of firecrackers. The number and position of the paper tubes 4 on the cake correspond one by one. The injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com