Light-weight measuring tool using carbon fiber material as measuring tool skeleton

A carbon fiber material and technology using carbon fiber, applied in the direction of measuring device, mechanical device, mechanical measuring device, etc., can solve the problems of easy deformation, insufficient strength of aluminum square tube, heavy weight, etc., and achieve the effect of high carbon fiber strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in detail with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the following examples.

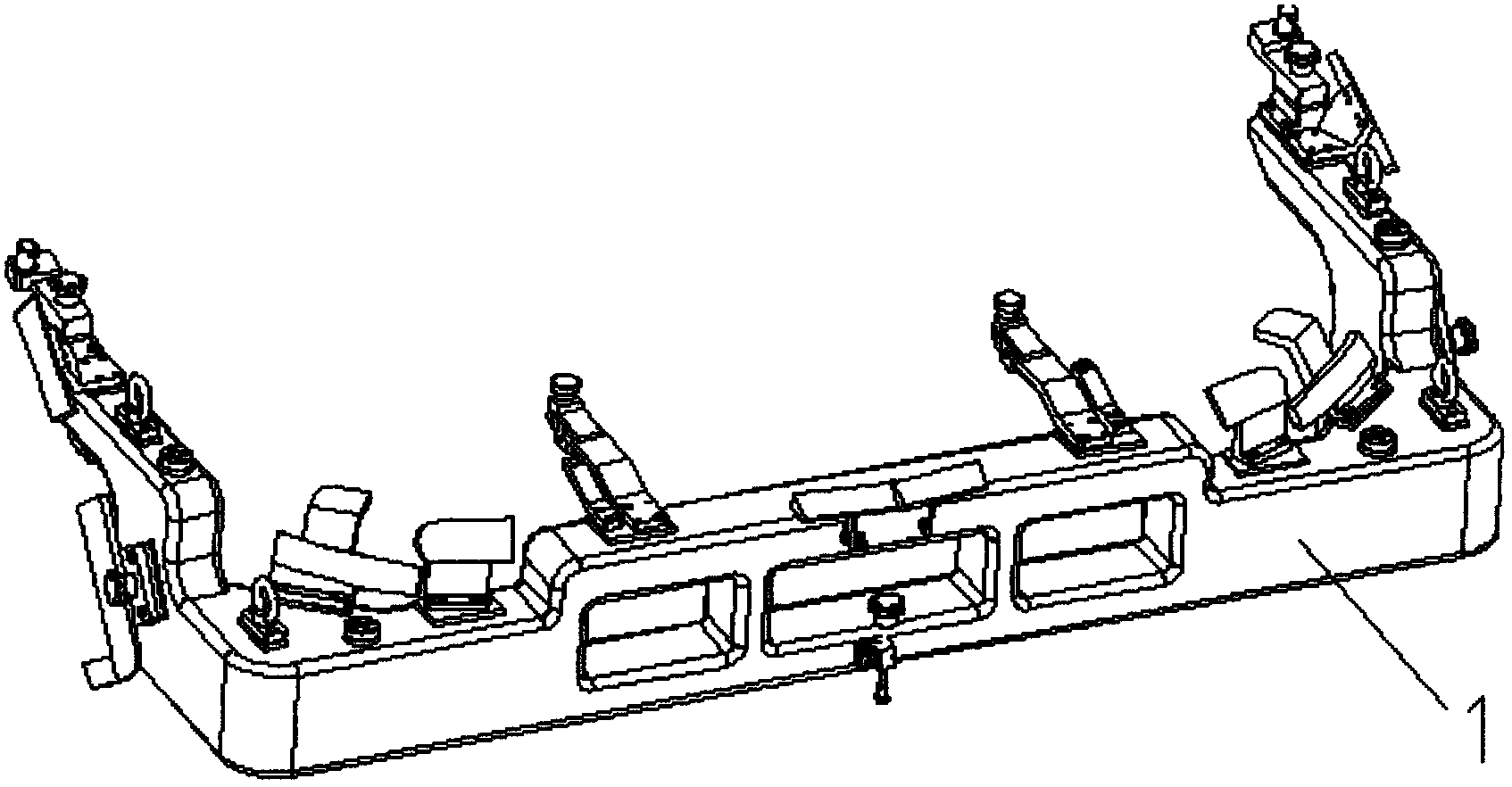

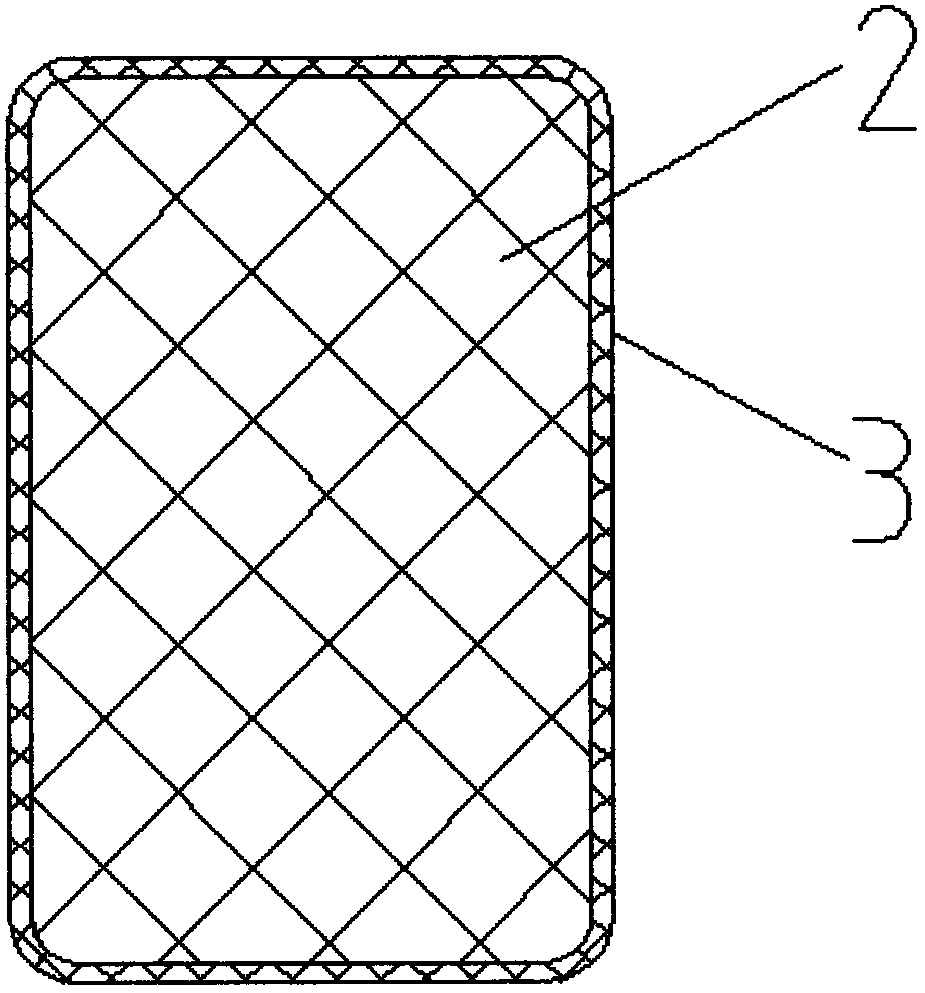

[0016] Such as figure 1 As shown, a lightweight checking fixture 1 using carbon fiber material as the skeleton of the checking fixture, the skeleton of the checking fixture includes: a polystyrene foam inner layer 2 and a carbon fiber cloth wrapped on the outer periphery of the polystyrene foam inner layer outer layer 3, figure 2 Shown is the cross-sectional schematic diagram of the inspection tool.

[0017] The lightweight inspection fixture can also be formed by stacking layers of carbon fiber cloth.

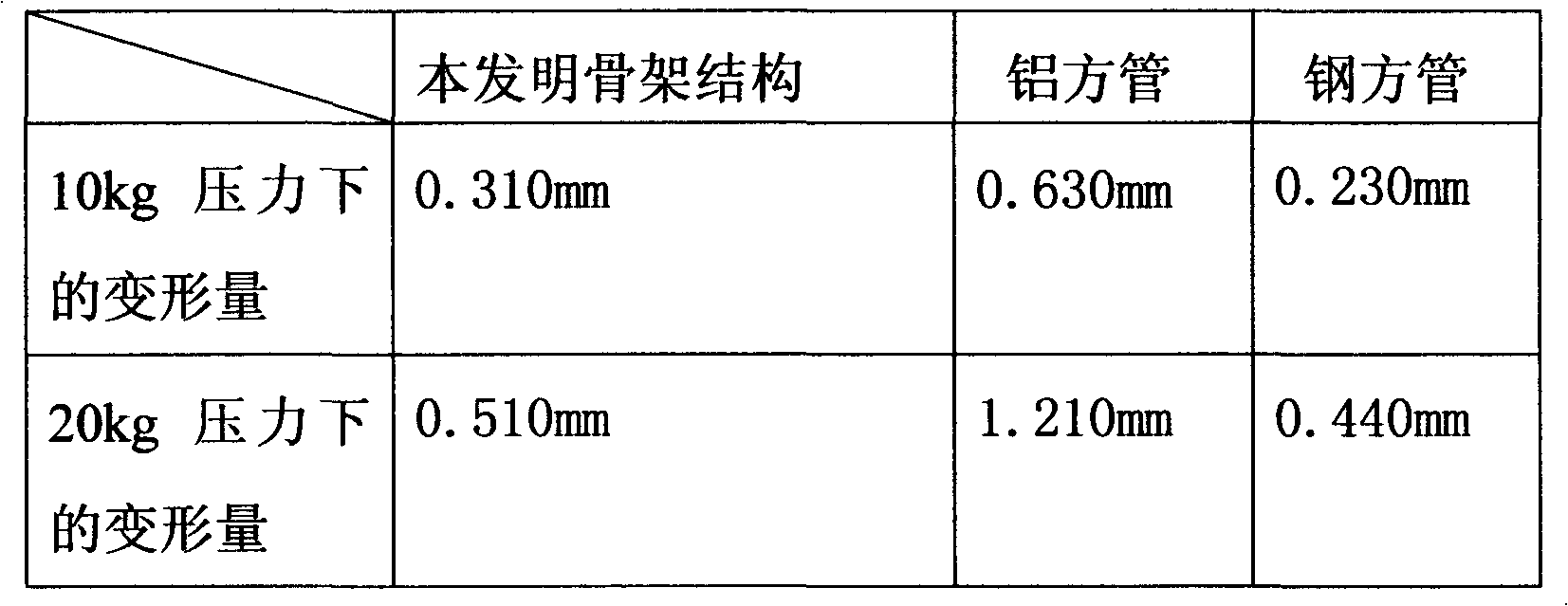

[0018] Take 40×40mm light-weight inspection fixtures of the present invention and inspection fixtures made of aluminum square pipes and steel square pipes respectively to test the deformation under a certain pressure. During the test, place two support blocks under them respectively. T...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap