Method for measuring positioning error of robot

A positioning error and robot technology, applied in the field of robot positioning error measurement, can solve the problem that the data acquisition process cannot be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

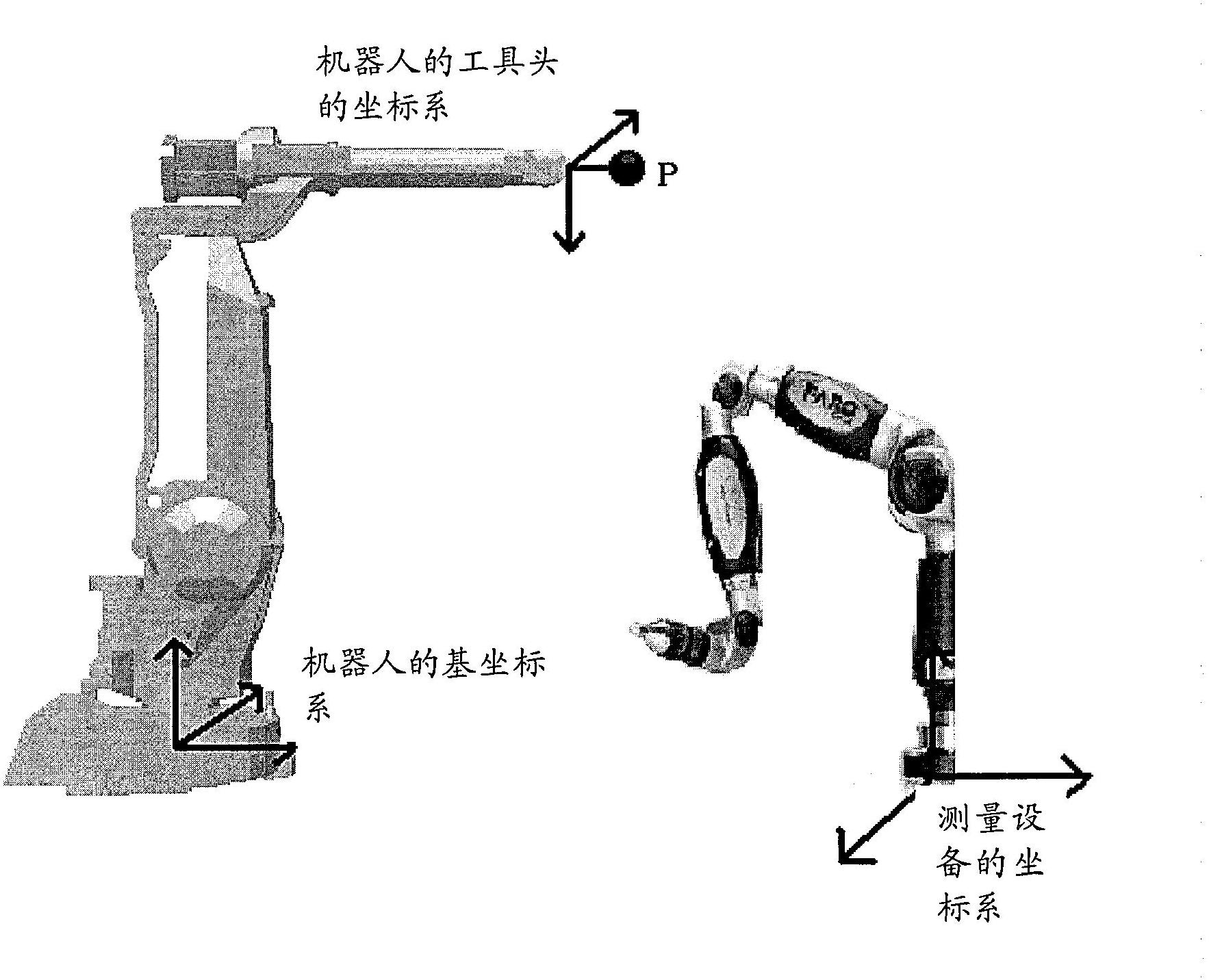

[0016] Positioning error measurement system of industrial robot based on FARO ARM

[0017] Such as figure 1 As shown, the industrial robot positioning error measurement system is composed of FARO ARM, measurement target and industrial robot. In the figure, P represents the target center to be measured, Base is the robot base coordinate system, Tool0 is the robot flange coordinate system, and Measure is the FARO ARM coordinate system.

[0018] In this industrial robot positioning error measurement system, FARO ARM can directly measure the coordinates of the target center P in the Measure coordinate system, and the robot itself can also be used as a measuring device to obtain the target center P grasped by the robot in the robot Base coordinate system The coordinates of the two can be unified into the same coordinate system through coordinate transformation, and then compared to obtain the position error of each measurement point of the industrial robot in its workspace. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com