Salt mist scratch test device

A scratch test and salt spray technology, applied in the mechanical field, can solve problems such as non-compliance with test requirements and manual scratches, and achieve the effects of improving test efficiency and quality, avoiding injuries, and simple and convenient scratch operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

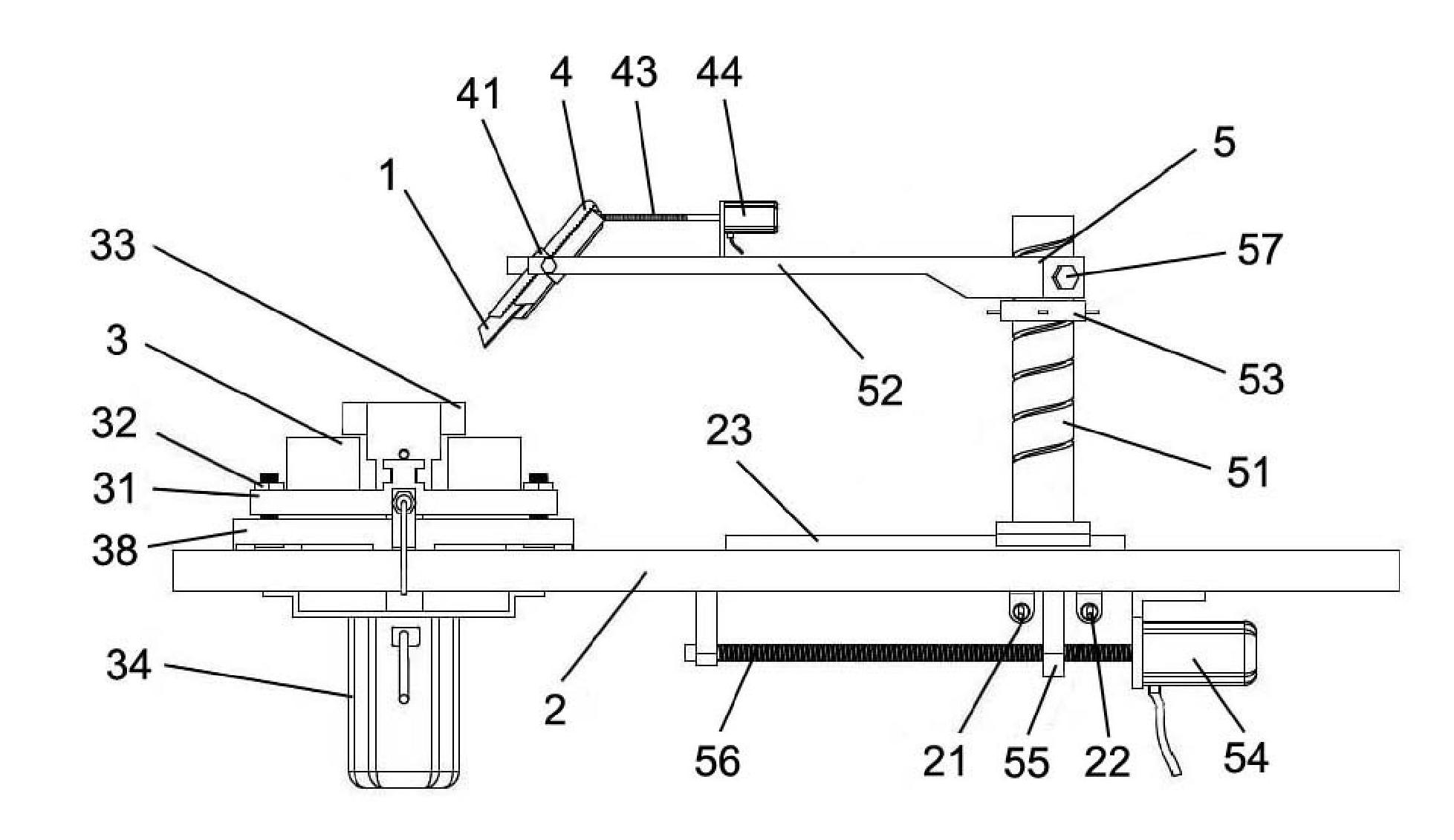

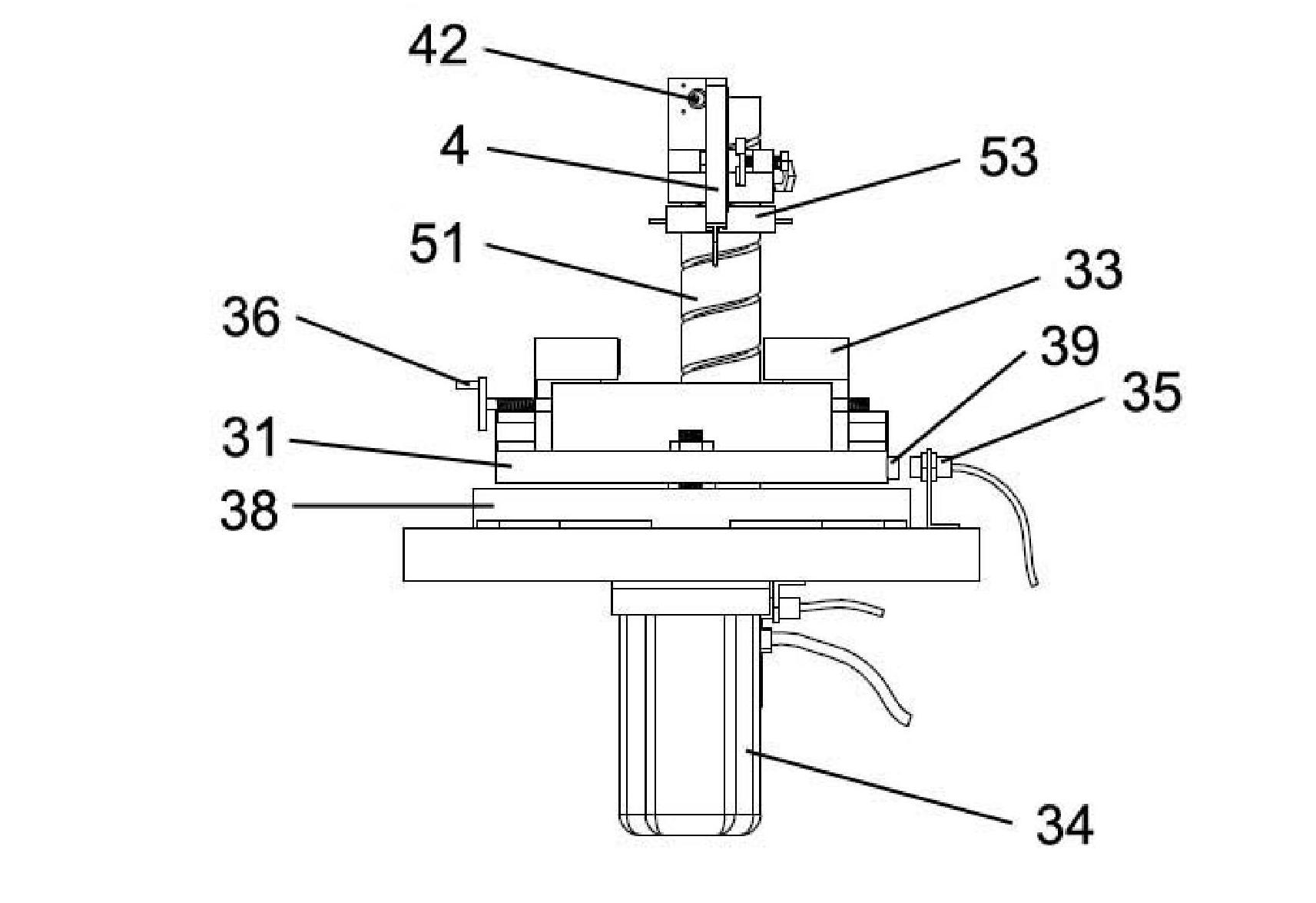

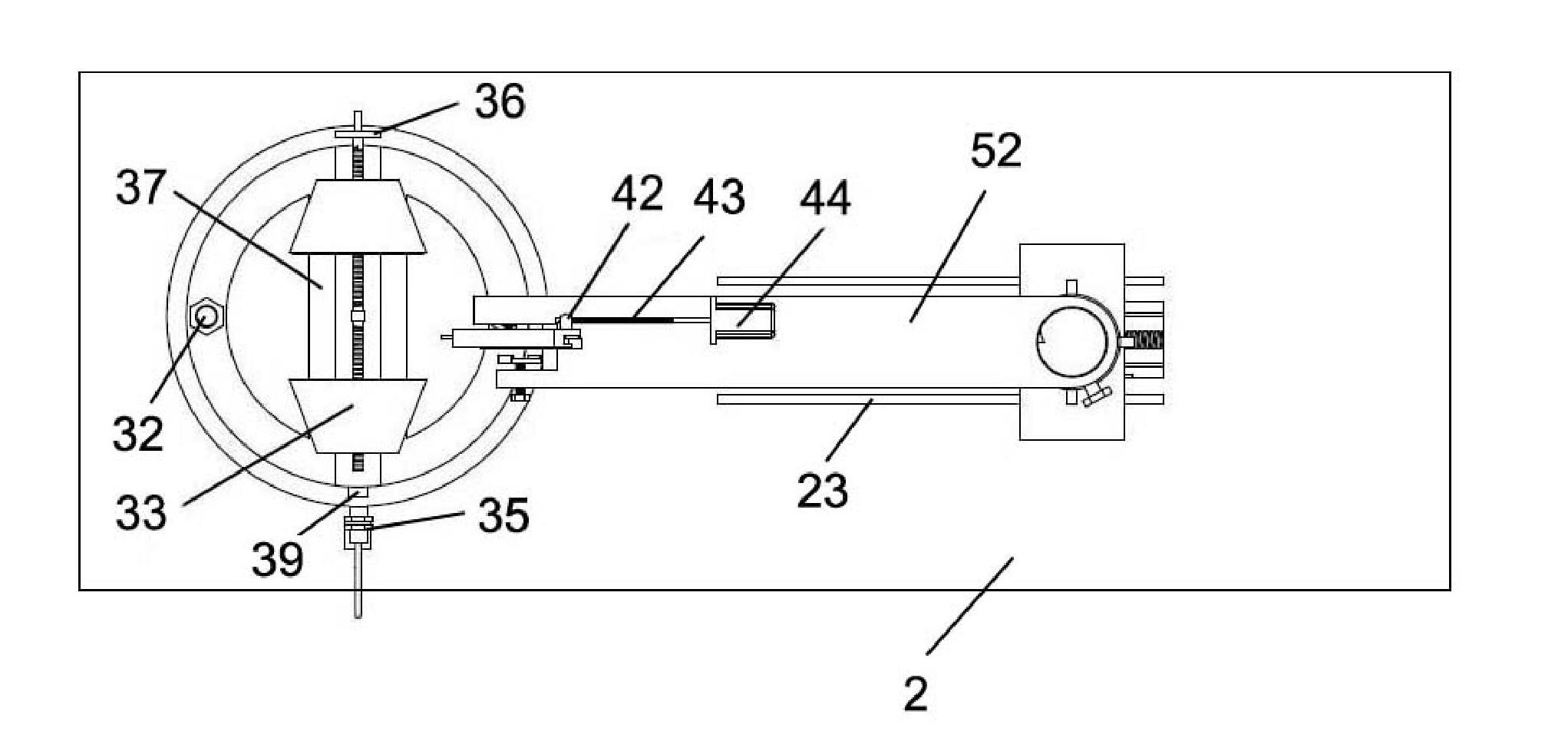

[0024] Such as figure 1 , 2 As shown in and 3, the salt spray scratch test equipment of the present invention includes: a base 2, a sample holder 3 arranged on the base 2, a tool mounting frame 5, and a tool holder 4 installed on the tool mounting frame 5 .

[0025] The tool mounting frame 5 may include a vertically extending tool support 51 and a horizontally extending tool holder 52 . In one embodiment, the upper surface of the base 2 may have a guide rail 23, on which the tool holder 51 is arranged and can slide horizontally along. The lower end portion 55 of the tool support 51 can pass through an open chute (not clearly shown) of the base 2 and extend to the bottom of the base 2 . The first driving mechanism is used to drive the tool support 51 to translate relative to the base 2 along the horizontal direction. In one...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com