Packing paper winding mechanism for capacitor, winder and packing paper winding method

A technology of capacitors and paper pads, applied in winding capacitor machines, capacitors, electrolytic capacitors, etc., can solve the problems of high defect rate, high cost, guide needle puncture, etc., to improve production efficiency, reduce defect rate, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

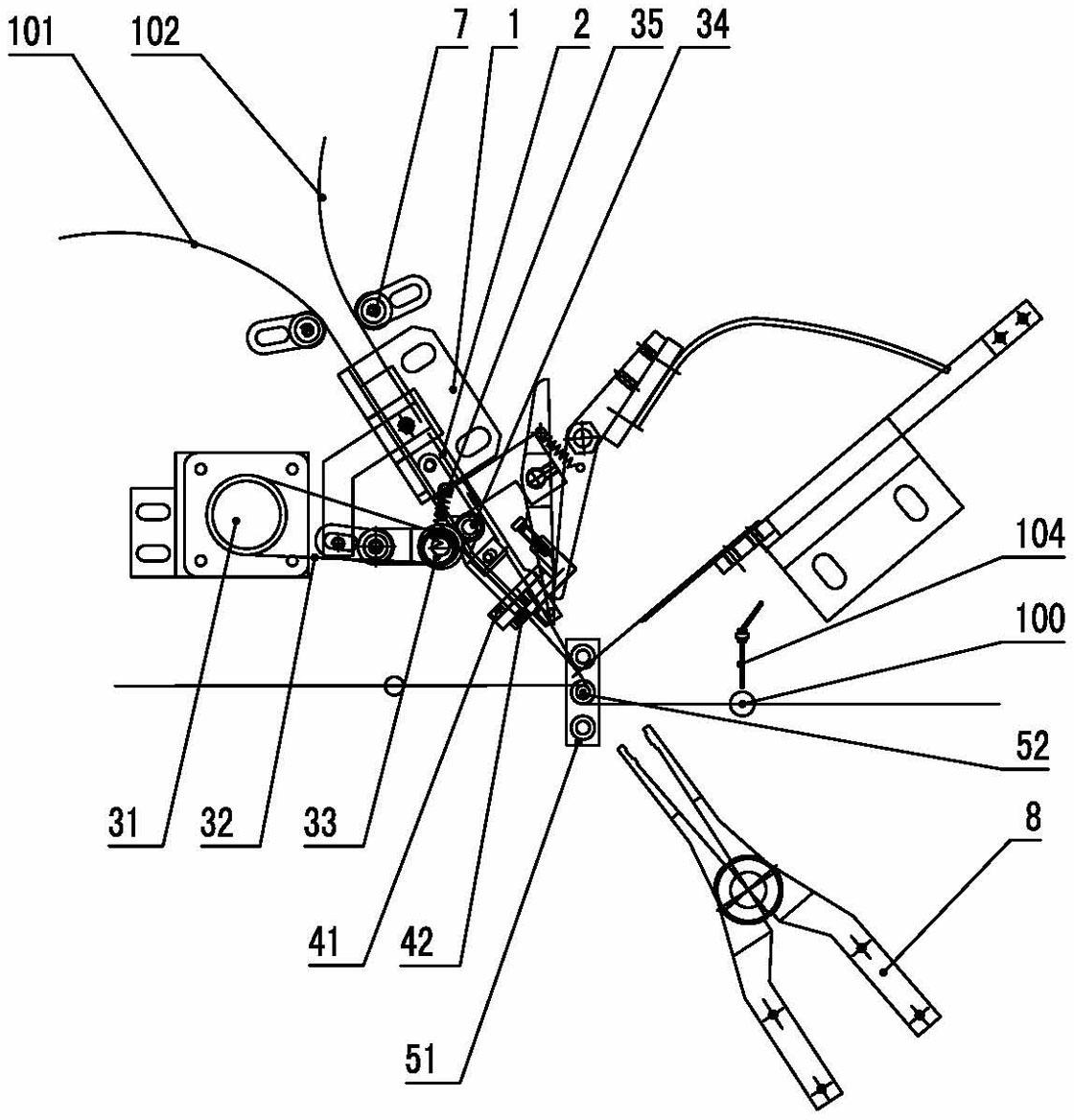

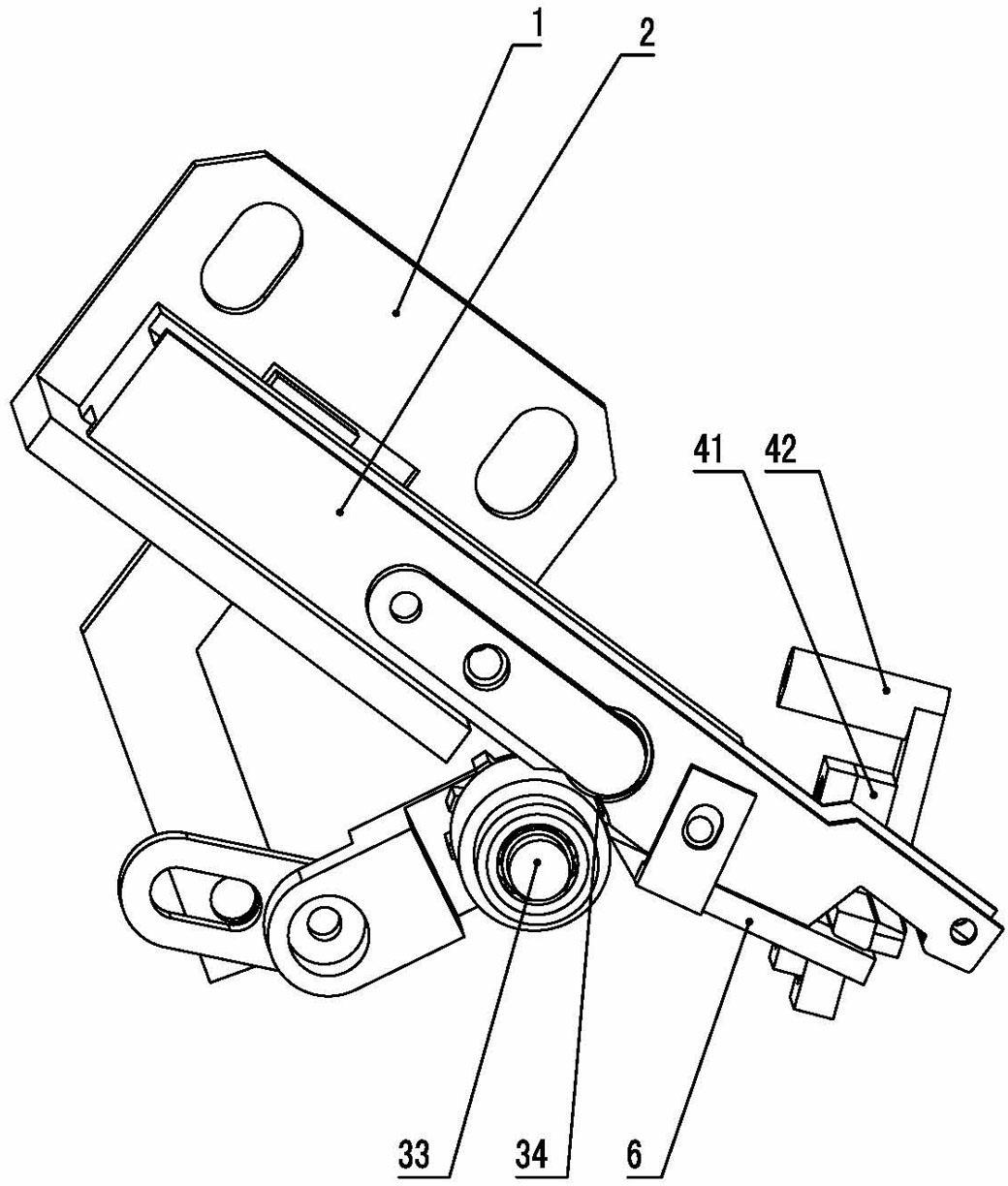

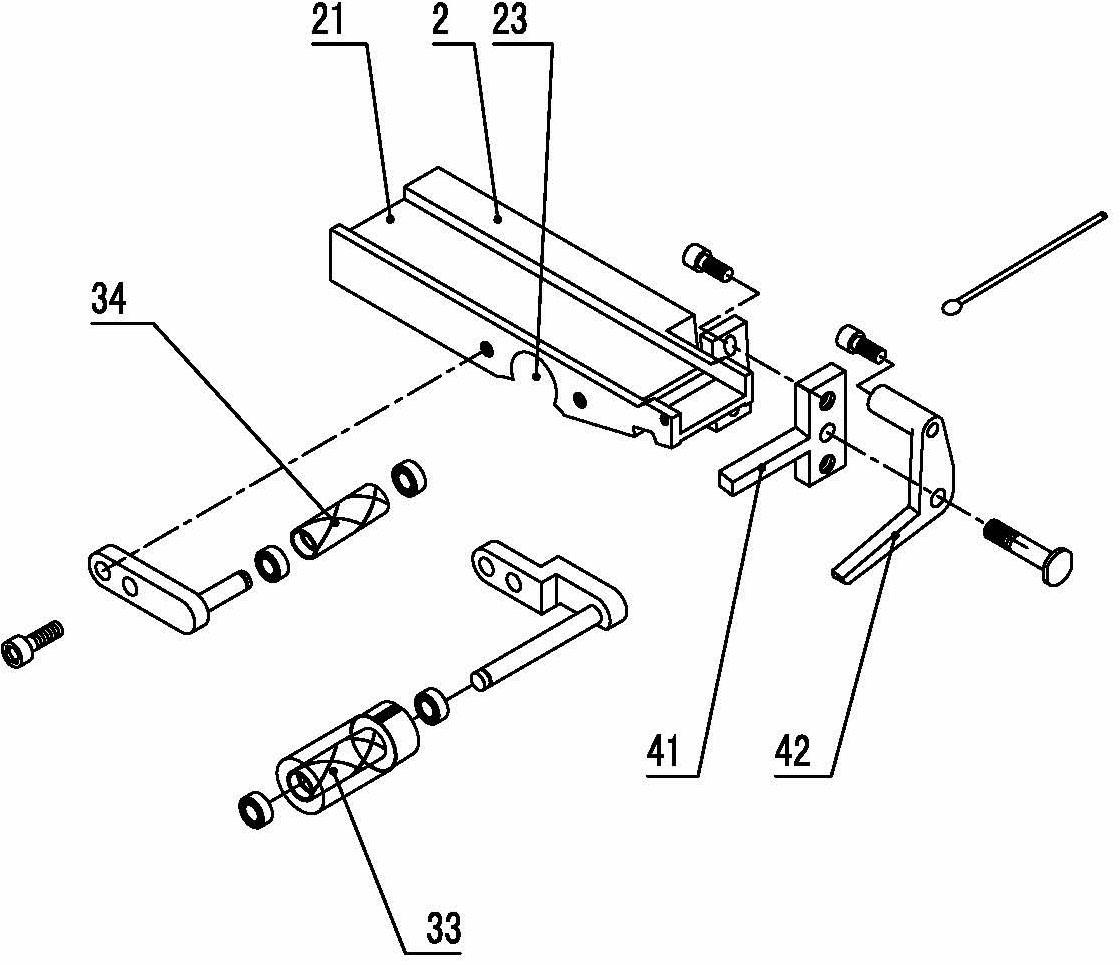

[0025] Figure 1 to Figure 5 The reference numerals in are: guide pin 100; backing paper 101; upper paper 102; guide pin position sensor 104; support 1; double track guide rail 2; upper paper guide rail groove 21; 23; arc-shaped avoidance part 24; pad paper feeding drive part 31; belt transmission mechanism 32; driving wheel 33; driven wheel 34; spring 35; fixed cutting arm 41; rotating cutting arm 42; roll paper support 51; roll paper Shaft 52; paper guide block 6; paper feeding guide wheel 7; paper pulling clip 8.

[0026] Such as Figure 1 to Figure 5 As shown, a pad paper winding mechanism for a capacitor includes a support 1, and the support 1 is provided with a double-track guide rail 2 that guides the upper layer of paper 102 and partially covers the pad paper 101 of the guide pin 100. The cutting mechanism for cutting the backing pap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com