Light-emitting diode structure with metal reflection surface and heat sink

A technology of light-emitting diodes and reflective structures, applied in semiconductor devices, lighting and heating equipment, cooling/heating devices for lighting devices, etc., can solve problems such as poor light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

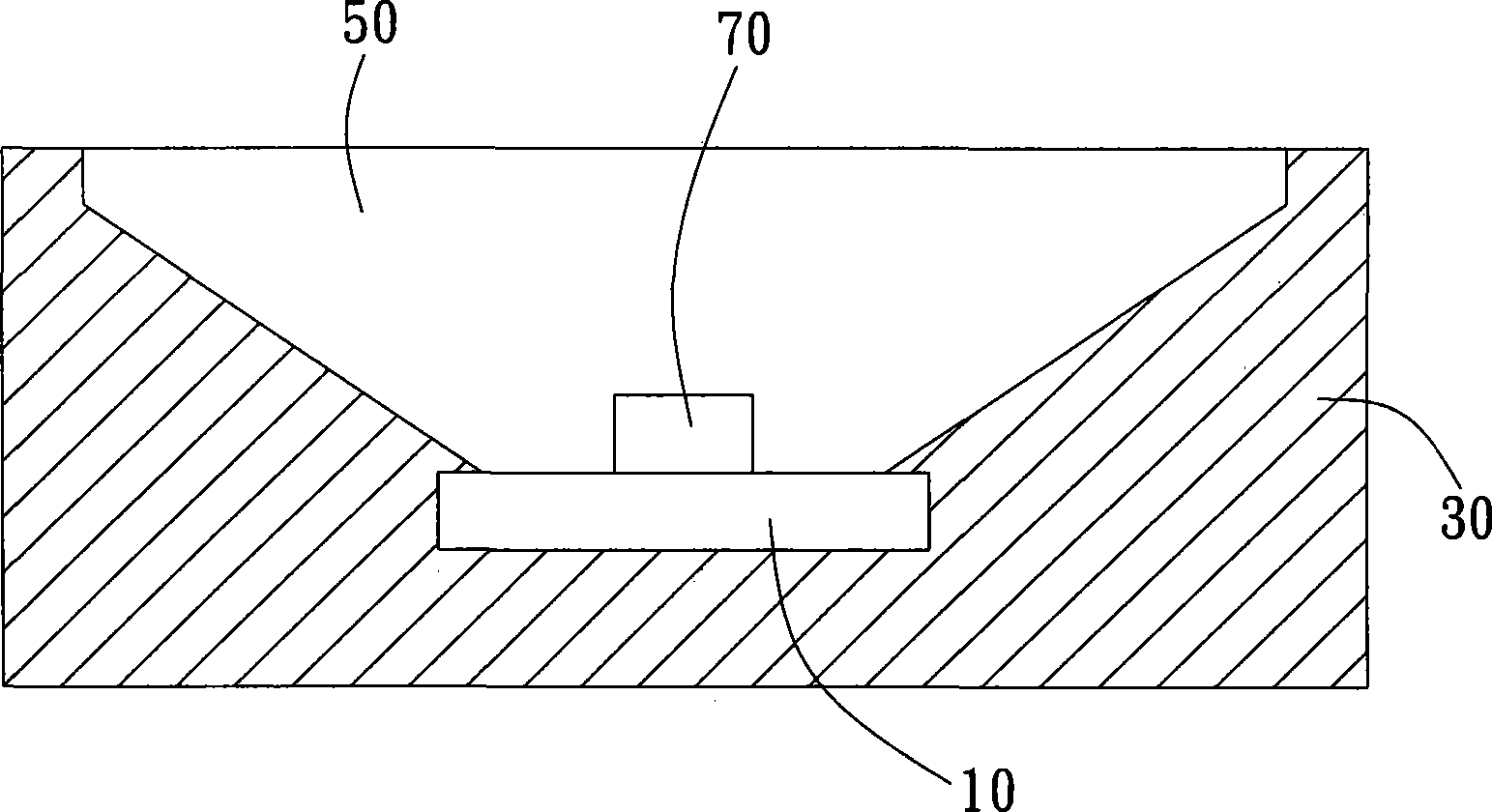

[0034] The invention provides a light-emitting diode with a metal reflective surface and a cooling block. The light-emitting diode structure mainly includes the metal bracket of the light-emitting diode; the metal material can be copper, copper alloy or a structure including silver plating on the metal reflective surface. In a preferred embodiment, the light-emitting diode can be used as a light-emitting diode lighting, a backlight source for a liquid crystal television or a liquid crystal panel.

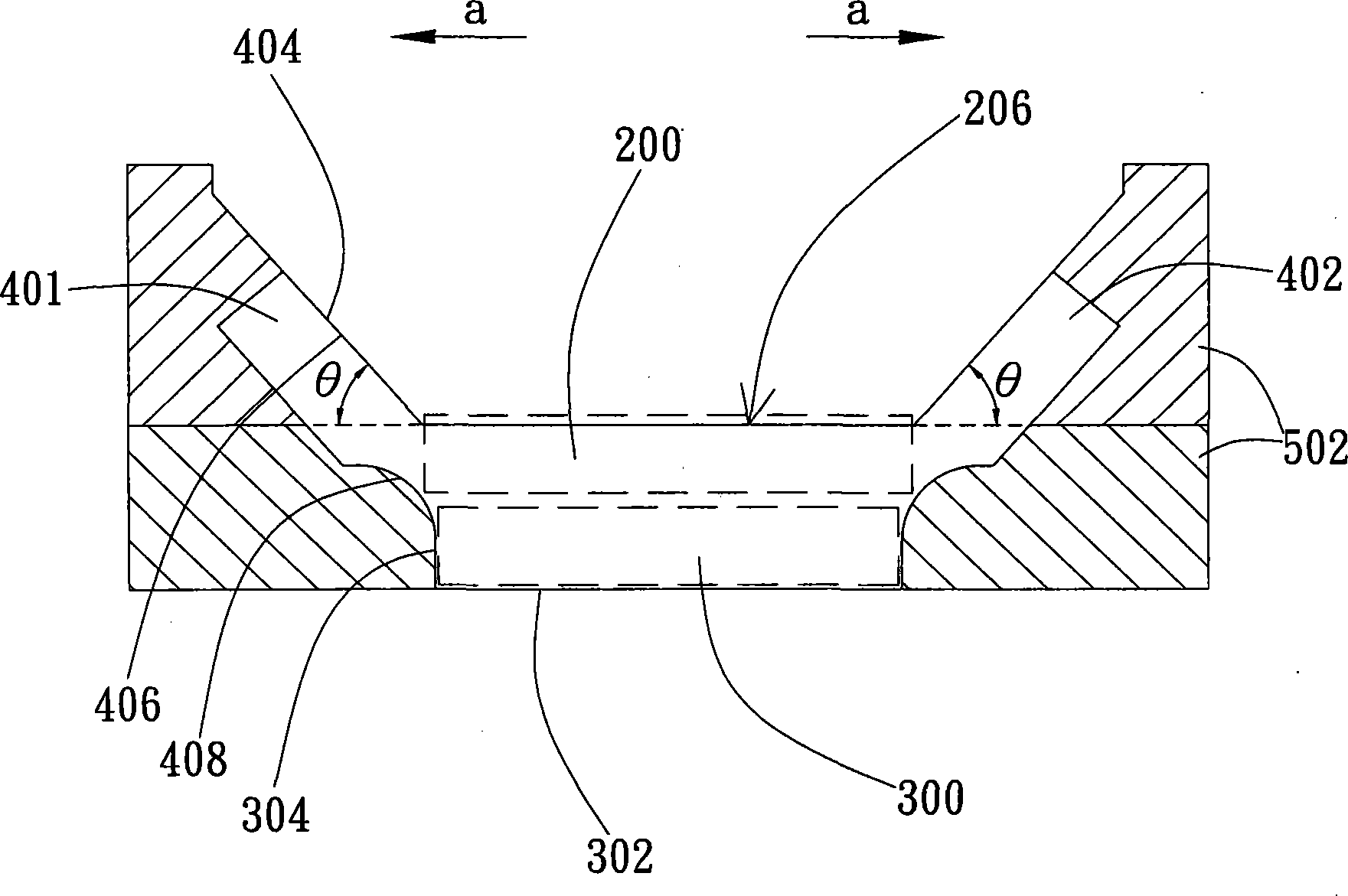

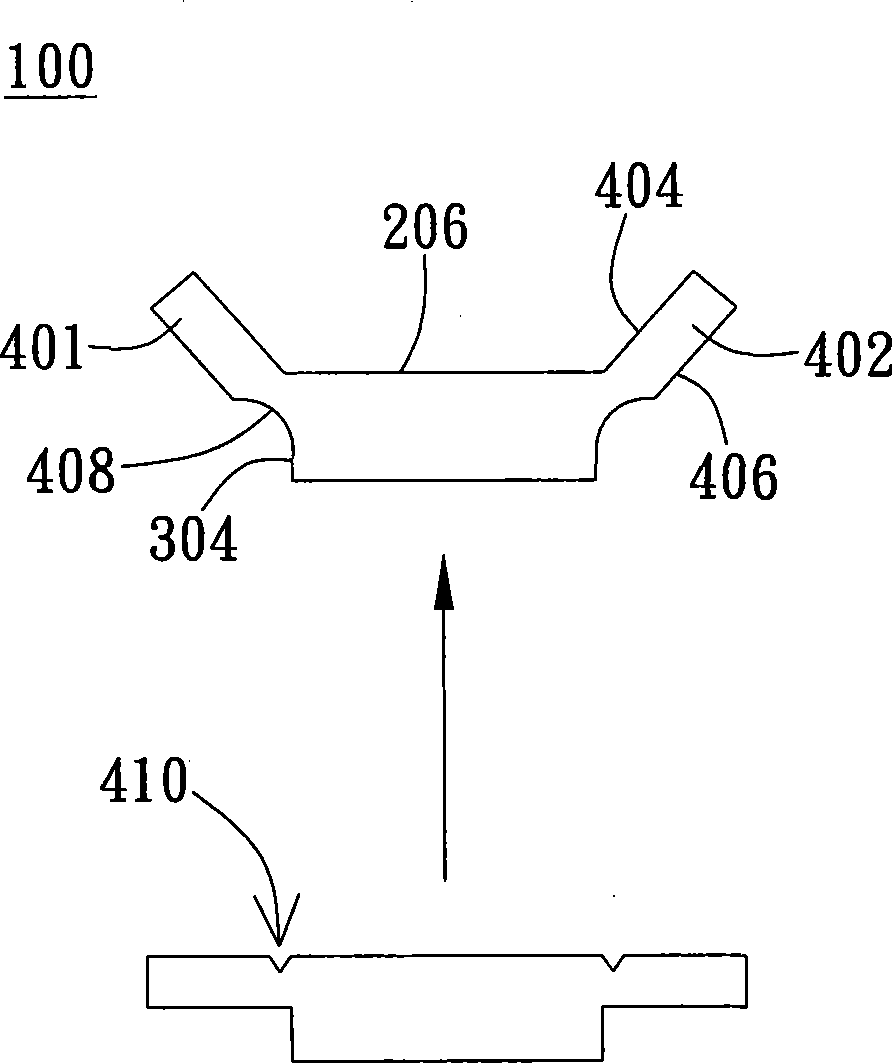

[0035] Such as figure 2 The sectional view of the light-emitting diode metal bracket 100 and the bowl cup structure 502 shown, the light-emitting diode metal bracket 100 mainly includes a platform part 200 and a heat dissipation part 300; the platform part 200 has a surface 206 and is located on the table surface 206 opposite The first reflective wing 401 and the second reflective wing 402 on one side 201 and the second side 202 . The first reflective wing 401 and the second refl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com