Creep-resistant aluminum alloy copper-aluminum transition terminal and preparation method thereof

A transition terminal and aluminum alloy technology, which is applied in the direction of metal/alloy conductors, contact manufacturing, multi-core cable end parts, etc., can solve problems such as poor welding performance, large contact resistance, and restrictions on popularization and application, and achieve improved thermal stability. The effect of safety and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

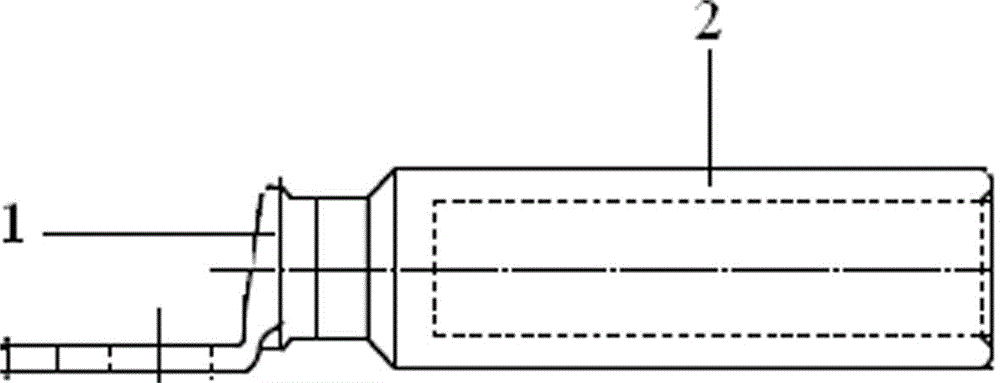

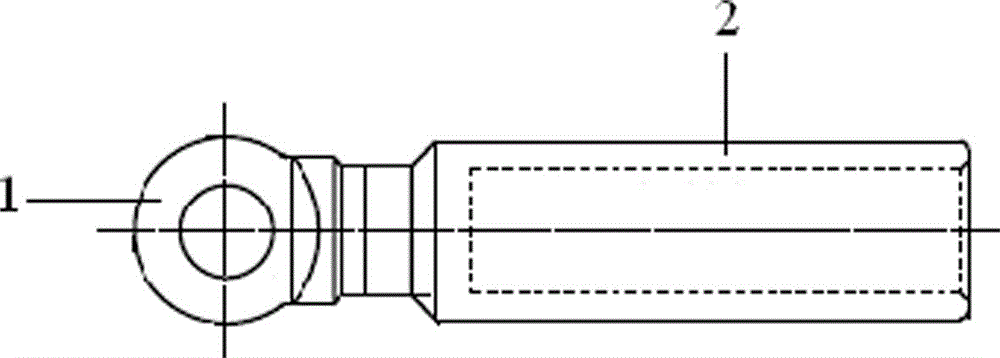

[0039] As shown in Figures 1 to 4, a creep-resistant aluminum alloy copper-aluminum transition terminal includes: a copper nose 1, an aluminum connecting pipe 2 connected to the copper nose 1, and the cross-sectional shape of the inner hole of the aluminum connecting pipe 2 is circular shape.

[0040] A method for preparing a creep-resistant aluminum alloy copper-aluminum transition terminal, the steps of which are as follows:

[0041] 1) Copper nose 1 is machined using T2 grade electrical copper rods according to the designed specifications and drawings;

[0042] 2) Use creep-resistant aluminum alloy to cast aluminum connecting pipes, and the mass percentage of chemical components of creep-resistant aluminum alloy is:

[0043] Si: 0.10, Fe: 0.50, Cu0.: 0.20, Mg: 0.03, Zn: 0.03

[0044] B: 0.02, the sum of other elements ≤ 0.1, Al balance.

[0045] 3) The copper nose 1 and the aluminum connecting pipe 2 are welded together by a friction welding process;

[0046] 4) After t...

Embodiment 2

[0048] As shown in Figures 1 to 4, a creep-resistant aluminum alloy copper-aluminum transition terminal includes: a copper nose 1, an aluminum connecting pipe 2 connected to the copper nose 1, and the cross-sectional shape of the inner hole of the aluminum connecting pipe 2 is fan-shaped .

[0049] 1) Copper nose 1 is machined using T2 grade electrical copper rods according to the designed specifications and drawings;

[0050] 2) Use creep-resistant aluminum alloy to cast aluminum connecting pipes, and the mass percentage of chemical components of creep-resistant aluminum alloy is:

[0051] Si: 0.10, Fe: 0.50, Cu0.: 0.20, Mg: 0.03, Zn: 0.03

[0052] B: 0.02, the sum of other elements ≤ 0.1, Al balance.

[0053] 3) The copper nose 1 and the aluminum connecting pipe 2 are welded together by a friction welding process;

[0054] 4) After trimming the copper-aluminum transition terminal, pack it into the warehouse.

Embodiment 3

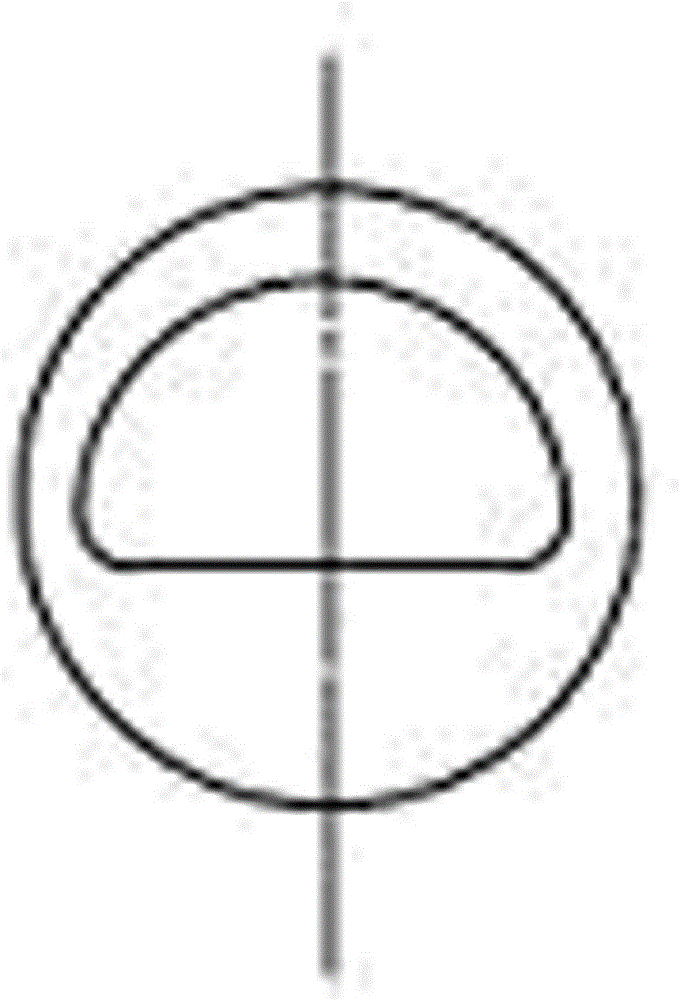

[0056] As shown in Figures 1 to 4, a creep-resistant aluminum alloy copper-aluminum transition terminal includes: a copper nose 1, an aluminum connecting pipe 2 connected to the copper nose 1, and the cross-sectional shape of the inner hole of the aluminum connecting pipe 2 is tile shape.

[0057] The preparation method of the anti-creep aluminum alloy copper-aluminum transition terminal of the present invention, its steps are as follows:

[0058] 1) Copper nose 1 is machined using T2 grade electrical copper rods according to the designed specifications and drawings;

[0059] 2) Use creep-resistant aluminum alloy to cast aluminum connecting pipes, and the mass percentage of chemical components of creep-resistant aluminum alloy is:

[0060] Si: 0.08, Fe: 0.75, Cu: 0.15, Mg: 0.01, Zn: 0.01

[0061] B: 0.009, the sum of other elements ≤ 0.1, Al balance.

[0062] 3) The copper nose 1 and the aluminum connecting pipe 2 are welded together by a friction welding process;

[0063]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com