High-performance aluminum alloy cable connection terminal

A cable connection, aluminum alloy technology, applied in the direction of conductive connection, electrical component connection, connection, etc., can solve the problems of low mechanical strength of aluminum conductors, poor welding performance, restrictions on promotion and application, and achieve less possibility of creep. , Improve mechanical strength, improve the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

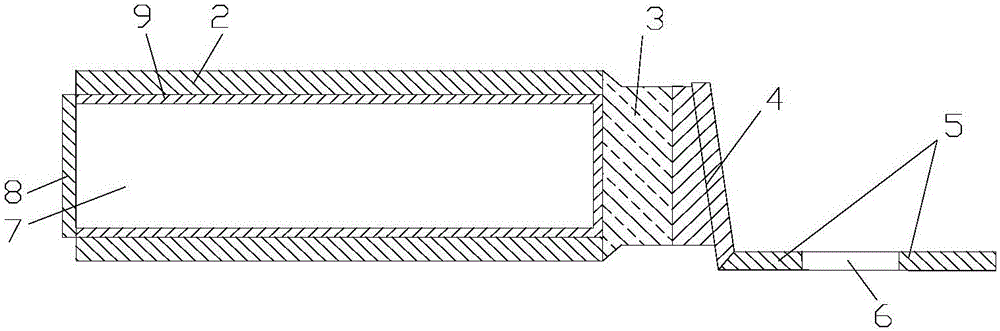

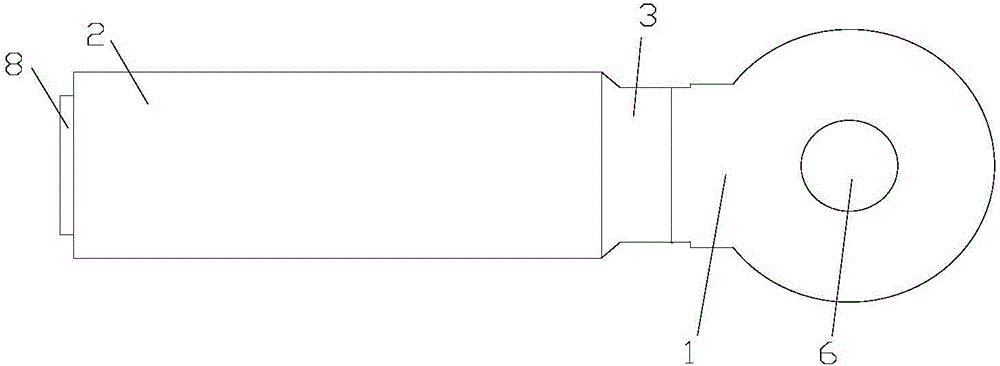

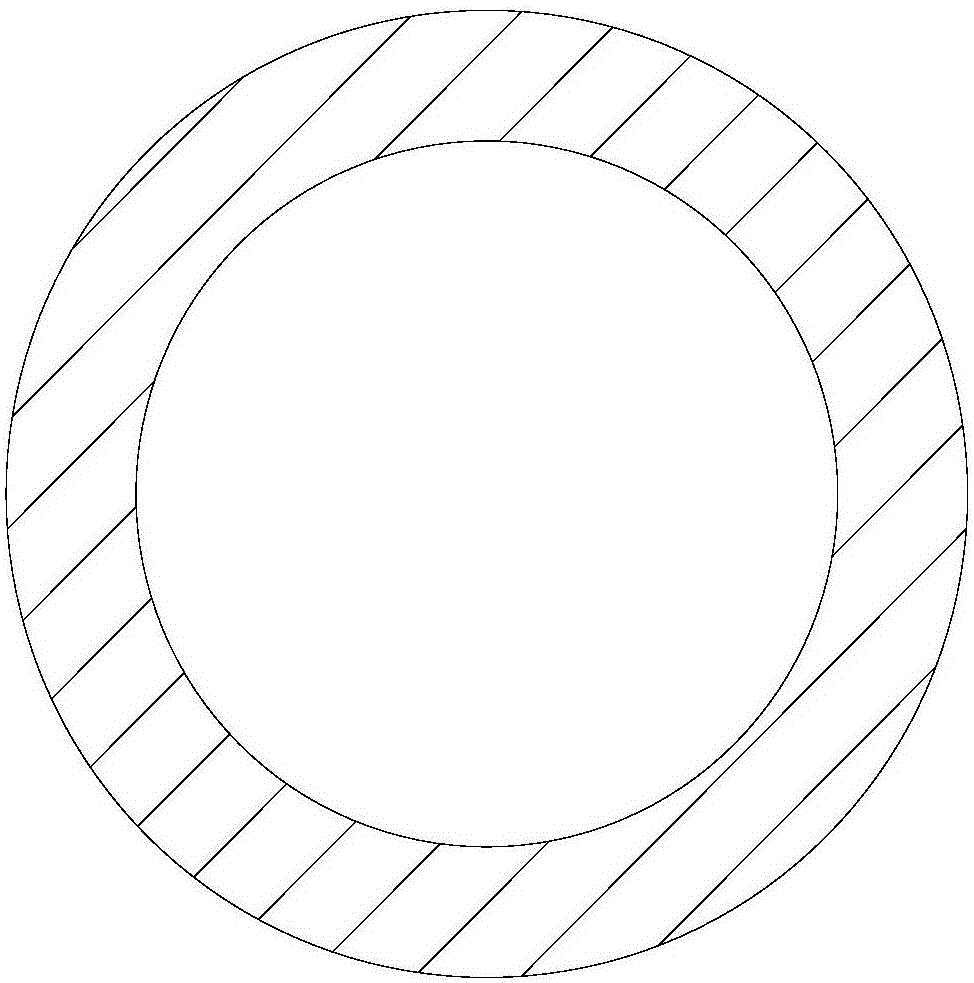

[0035] Specific embodiment 1, such as Figure 1 to Figure 3As shown, a high-performance aluminum alloy cable connection terminal includes a connecting lug 1, a connecting pipe 2, and a copper-aluminum transition part 3 arranged between the connecting lug 1 and the connecting pipe 2; the longitudinal section of the connecting lug 1 is L-shaped, and its The transverse part is a sheet-shaped fixing part 4 provided with a through hole 6, and its longitudinal part is a cylindrical connecting part 5. The fixing part 4 is arranged on one side of the end face of the connecting part 5 and has an angle of 90° with the end face of the connecting part 5. If the included angle is too small, it is not conducive to the fixing of the wiring nose 1, if the included angle is too large, the contact area of the connection is small, and it is easy to break; The cross-sectional shape of the low-voltage power cable is the same as that of the low-voltage power cable. The cross-sectional shape of th...

Embodiment 2

[0074] Such as figure 1 , figure 2 and Figure 4 As shown, a high-performance aluminum alloy cable connection terminal includes a connecting lug 1, a connecting pipe 2, and a copper-aluminum transition part 3 arranged between the connecting lug 1 and the connecting pipe 2; the longitudinal section of the connecting lug 1 is L-shaped, and its The transverse part is a sheet-shaped fixing part 4 provided with a through hole 6, and its longitudinal part is a cylindrical connecting part 5. The fixing part 4 is arranged on one side of the end face of the connecting part 5 and the included angle with the end face of the connecting part 5 is 135°; The connecting pipe 2 is a hollow pipe with a wire insertion hole 7 in the axial direction. The cross-sectional shape of the wire insertion hole 7 is fan-shaped.

[0075] The wiring lug 1 of the connecting terminal in the above structure is made of T1 grade electrical copper, and the specific components include: copper and silver 99.95%; ...

Embodiment 3

[0088] Such as figure 1 , figure 2 and Figure 5 As shown, a high-performance aluminum alloy cable connection terminal includes a connecting lug 1, a connecting pipe 2, and a copper-aluminum transition part 3 arranged between the connecting lug 1 and the connecting pipe 2; the longitudinal section of the connecting lug 1 is L-shaped, and its The transverse part is a sheet-shaped fixing part 4 provided with a through hole 6, and its longitudinal part is a cylindrical connecting part 5. The fixing part 4 is arranged on one side of the end face of the connecting part 5 and the included angle with the end face of the connecting part 5 is 125°; The connecting pipe 2 is a hollow pipe with a wire insertion hole 7 in the axial direction. The cross-sectional shape of the wire insertion hole 7 is tile-shaped. .

[0089] The connecting lug 1 of the connecting terminal in the above structure is made of T1 grade electrical copper, and the specific components include: copper and silver ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com