Permanent-magnet wind-driven generator capable of realizing self-acceleration of magnetic field

A technology for wind power generators and generators, applied in the directions of magnetic circuit static parts, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc. To solve the problems of large size and high failure rate of high-speed gears, it achieves the effects of convenient processing and manufacturing, armature winding, reduced maintenance costs, and high torque density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the drawings.

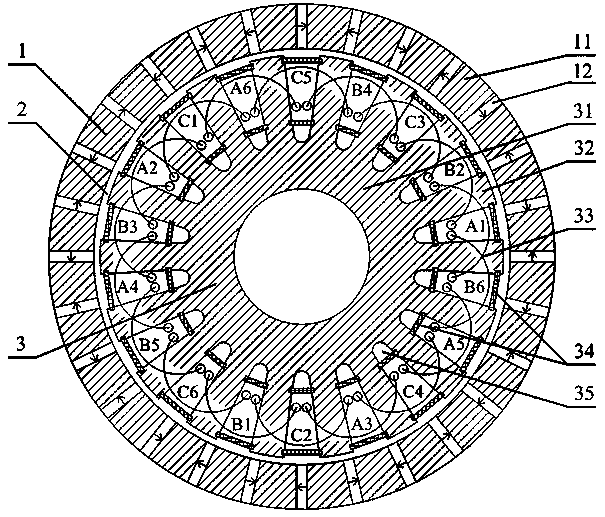

[0021] The invention provides a permanent magnet wind power generator with a magnetic field self-increasing function. The generator includes a rotor, an air gap and a stator arranged concentrically from the outside to the inside. The air gap is located between the rotor and the stator to ensure The rotor rotates; the rotor includes a number of rotor cores arranged at equal intervals and rotor permanent magnets embedded between adjacent rotor cores; the stator includes a stator yoke coaxial with the rotor, and a number of stators protruding from the outer circumference of the stator yoke The stator teeth are provided with slots between adjacent stator teeth. The stator also includes armature windings embedded in the slots between the stator teeth. The stator teeth adopt a straight-tooth structure, and the stator teeth include a tooth root close to the stator yoke and a tooth The roots ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com