Chemical method for promoting sweetgum to produce lipid

A chemical method, lanolin technology, applied in botany equipment and methods, chemicals for biological control, horticultural methods, etc., can solve problems affecting the normal growth of sweetgum trees, wood utilization, and damage to tree bark

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

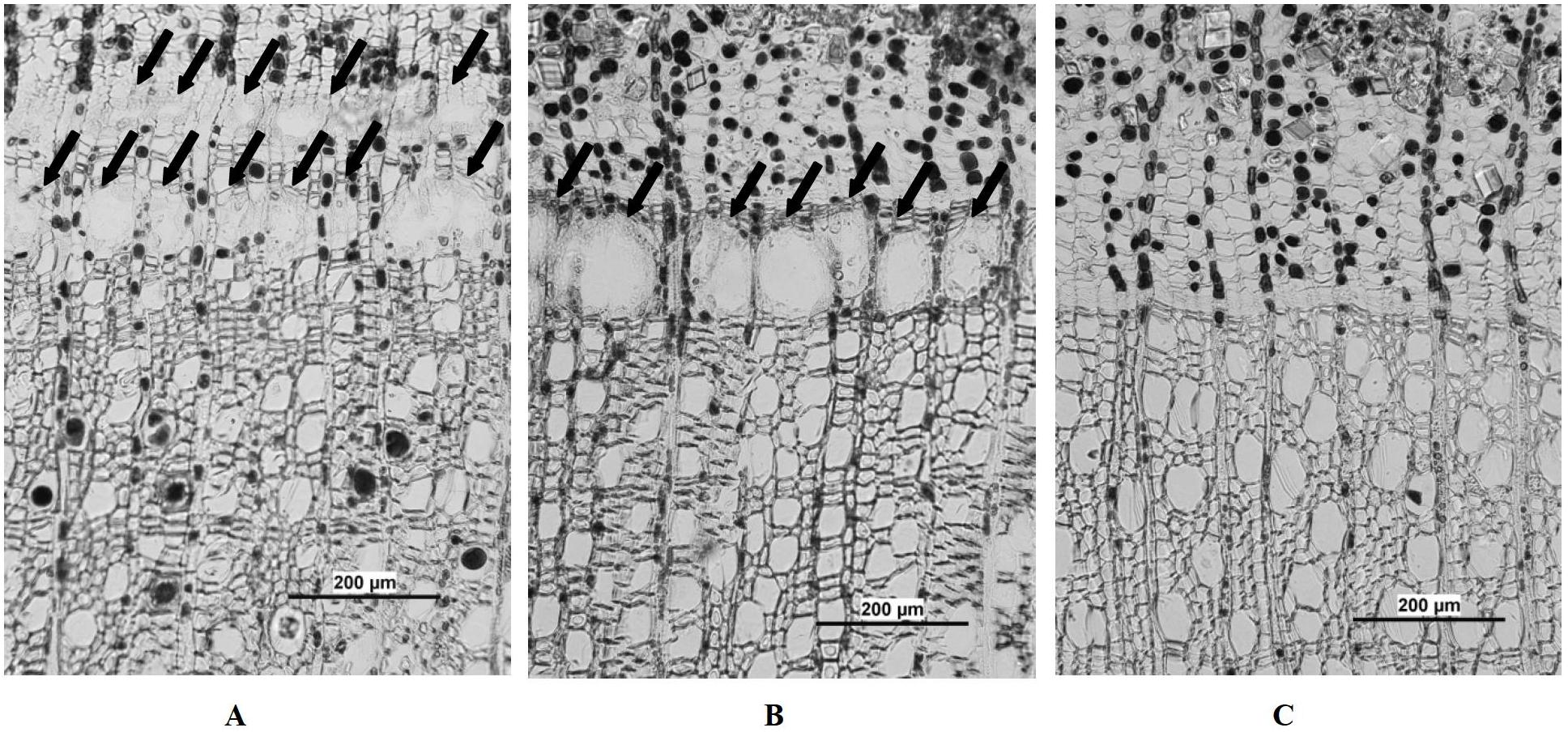

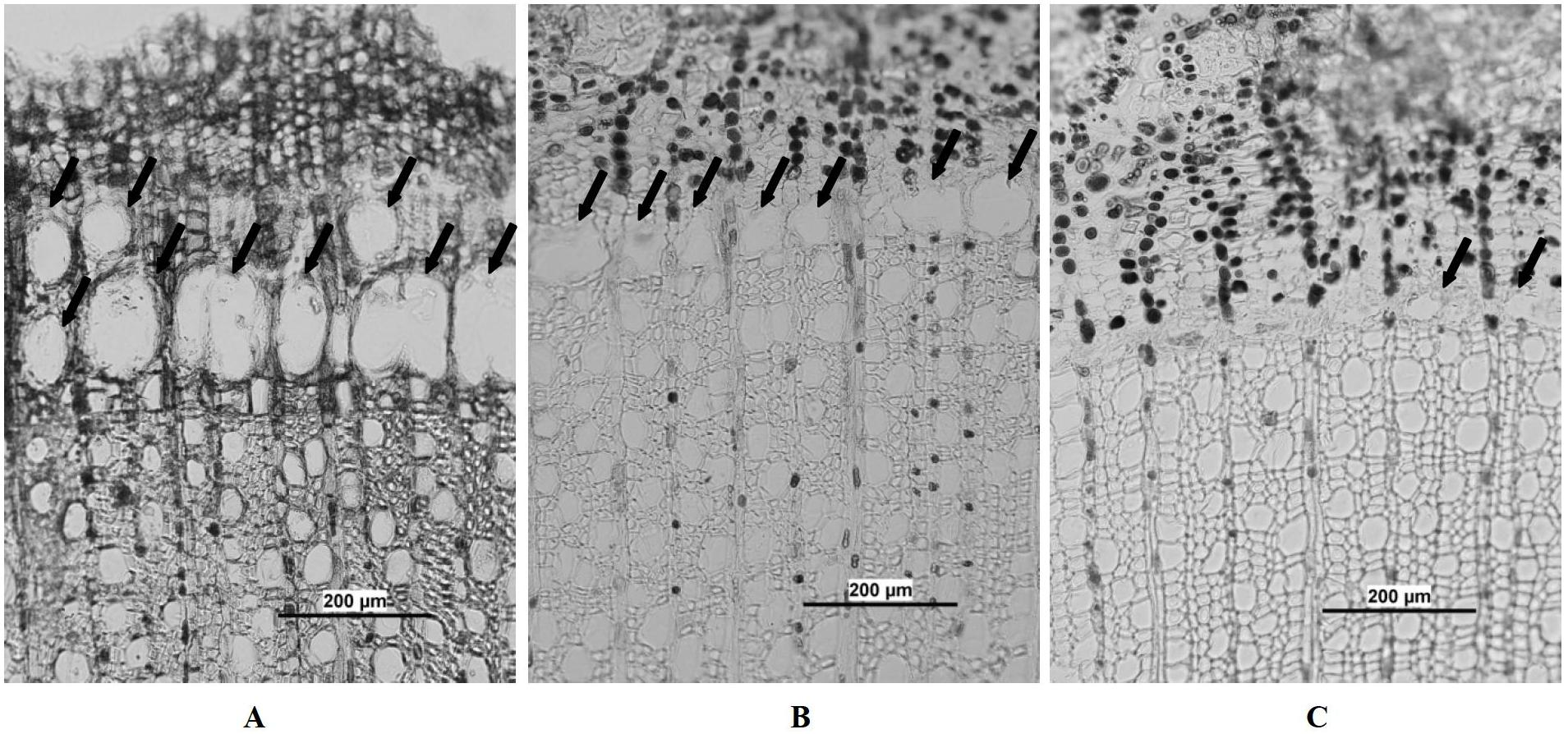

[0025]In May, July and September 2010, lanolin containing 1%, 2% and 5% mass concentration of methyl jasmonate, ethephon and ethephon-methyl jasmonate (1:1 mixture) , respectively treat the liquidambar of group A, group B and group C, and process the liquidambar of group D with lanolin without any reagent at the same time, and apply the reagent on the surface of the liquidambar trunk to form a 3mm thick, 3cm high Coating units, each coating unit is spaced 15cm apart ( Figure 10 B). As of October 2010, naked eye observation showed that there was no glue flow in group A treated with methyl jasmonate and group D as a comparison group, and there was glue flow in group B treated with ethephon and group C treated with mixed reagents , and through observation, it was found that there were more gums in the treated parts in May, and the trunks were mostly soaked by gums, with the special fragrance of sweetgum gum.

[0026] The samples treated with 1%, 2%, and 5% mass concentrations ...

Embodiment 2

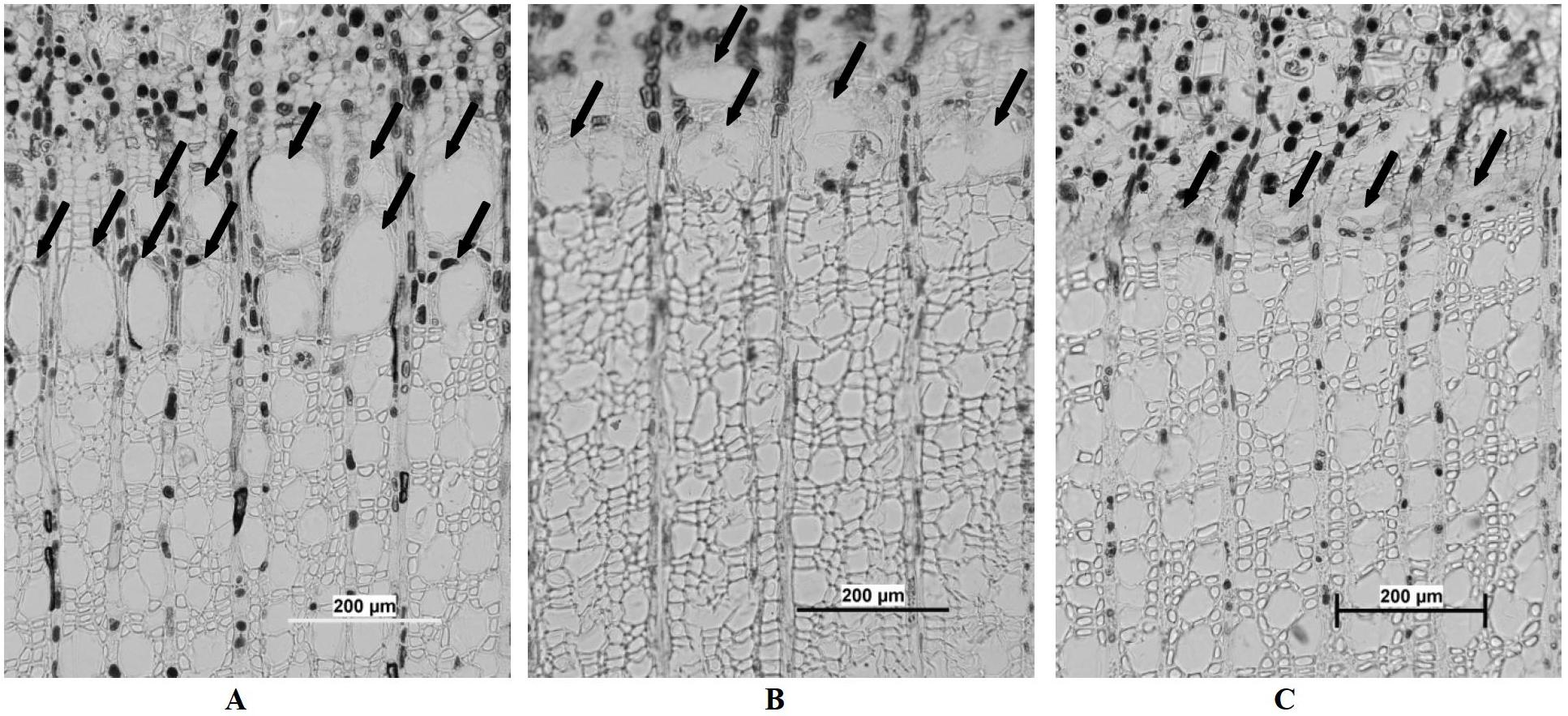

[0055] After mixing methyl jasmonate and ethephon at a mass ratio of 1:1, the mixture is added to lanolin at a mass ratio of 1%, and then coated on the surface of sweetgum tree trunks from May to July, Coating units 3mm thick and 3cm high were formed with 30cm intervals between each coating unit. Observation with the naked eye showed that there was obvious gum flow in the coated area, and it was found that the amount of gum was the largest in the part treated in May, and the trunk was soaked by the gum, with a special fragrance of sweetgum gum.

Embodiment 3

[0057] After mixing methyl jasmonate and ethephon at a mass ratio of 1:1, the mixture is added to lanolin at a mass ratio of 5%, and then coated on the surface of sweetgum tree trunks from May to July, Coating units of 3 mm thick and 3 cm high were formed with 20 cm intervals between each coating unit. Observation with the naked eye showed that there was obvious gum flow in the coated area, and it was found that the amount of gum was the largest in the part treated in May, and the trunk was soaked by the gum, with a special fragrance of sweetgum gum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com