Waterborne flying ship

A technology for flying ships and ships on water, which is applied in the direction of hull, ship propulsion, ship parts, etc., can solve the problems of reducing the water removal efficiency of the driving wheel, weakening a small number of benefits, and unfavorable the installation angle of conventional paddle wheels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0164] like Figure 4 As shown, the watercraft of this embodiment includes a streamlined hull 6, a power system including a centrifugal turbine, a high-speed driving balance system, a rudder and other parts, the centrifugal turbine is installed at the lower part of the hull, and some turbine blades 2 extend downward. When exposed below the bottom of the hull, the height of the exposed portion is preferably about a quarter of the diameter of the turbine and less than the radius of the turbine; the rudder is mounted on the stern of the hull and is centrally arranged.

[0165] The high-speed running balance system of this embodiment includes a lateral balance formed by symmetrically arranging synchronously rotating centrifugal turbines on both sides of the hull, and a longitudinal balance formed by arranging two rows of centrifugal turbines at the front and rear of the hull.

[0166] The rudder of this embodiment consists of two parts, one part is a rudder 7 similar to a conventi...

Embodiment 2

[0173] Figure 40 and Figure 41 As shown, the difference between this embodiment and the above-mentioned first embodiment is that the watercraft of this embodiment is provided with three or more rows of centrifugally driven turbines at the front and rear of the hull.

Embodiment 3

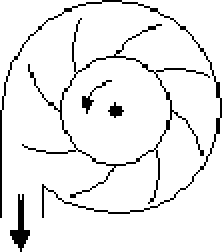

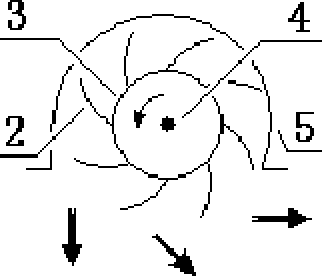

[0175] like image 3 and Image 6 , Figure 8 As shown, the difference between this embodiment and the above two embodiments is that there is a fairing 5 above the centrifugal turbine in this embodiment, and the turbine part larger than the radius of the centrifugal turbine is sealed in the upper fairing 5, which occupies less than the centrifugal turbine. The turbine blades 2 of the part below the turbine radius protrude downward from the fairing 5 and are exposed below the bottom of the ship, and the exposed turbine blades 2 are higher than a quarter of the turbine diameter; the centrifugal turbine used in the present invention is corresponding to the conventional centrifugal turbine. The location of the water pump outlet (or the exhaust outlet of conventional centrifugal air pumps) (see Figure 1-2 ), opening the larger opening (see figure 2 and image 3 ), the opening is at the bottom of the ship (see Image 6 , Figure 7 ), the turbine blade 2 is exposed from this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com