Servo driving device of paper brick-shaped germ-free filling machine

A technology of servo drive device and filling machine, which is applied in the direction of packaging machine, packaging, transportation and packaging, etc. It can solve the problems of processing, installation, debugging errors, difficult speed increase, loud voice, etc., and achieves easy stroke adjustment and convenient operation , the effect of free speed regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

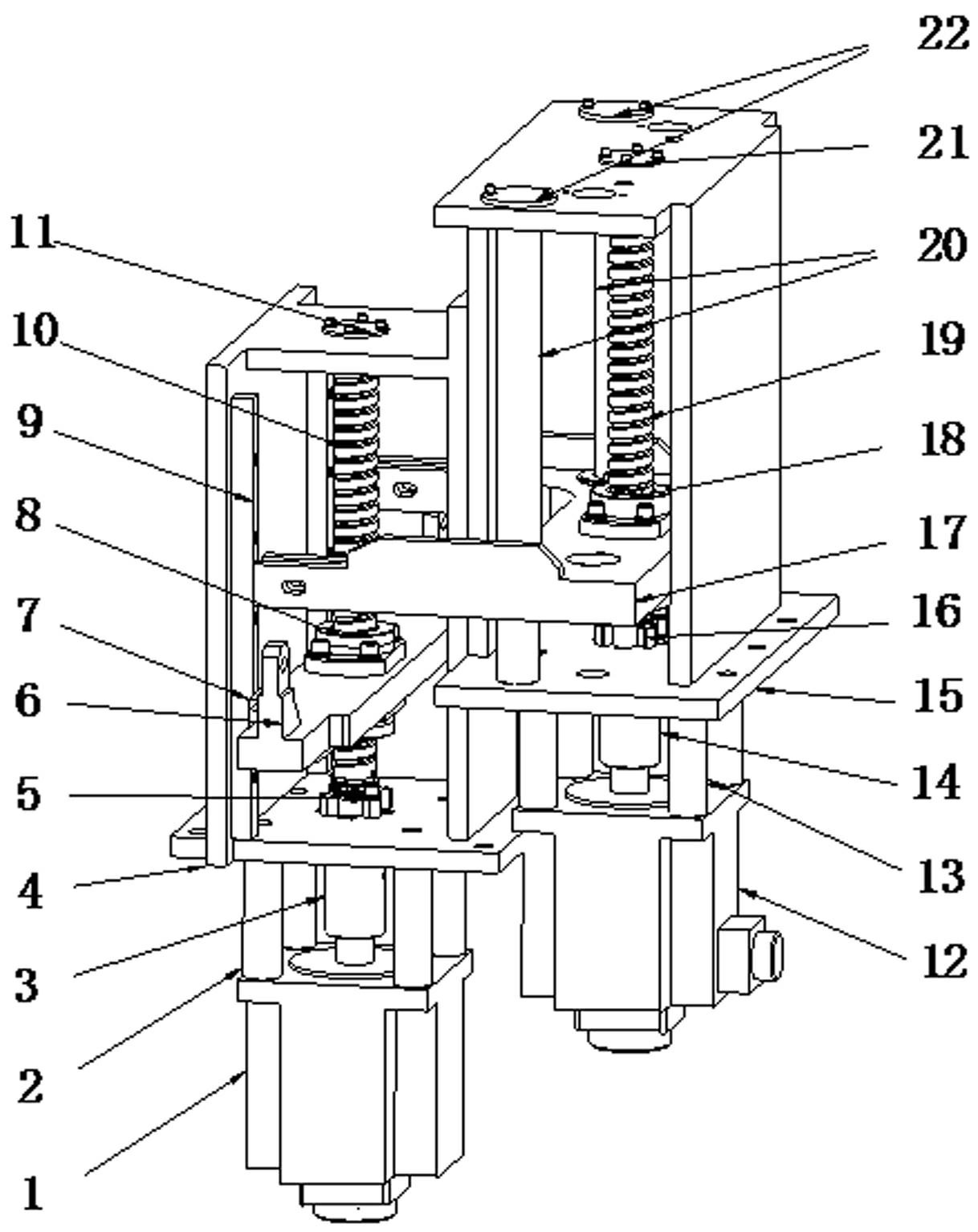

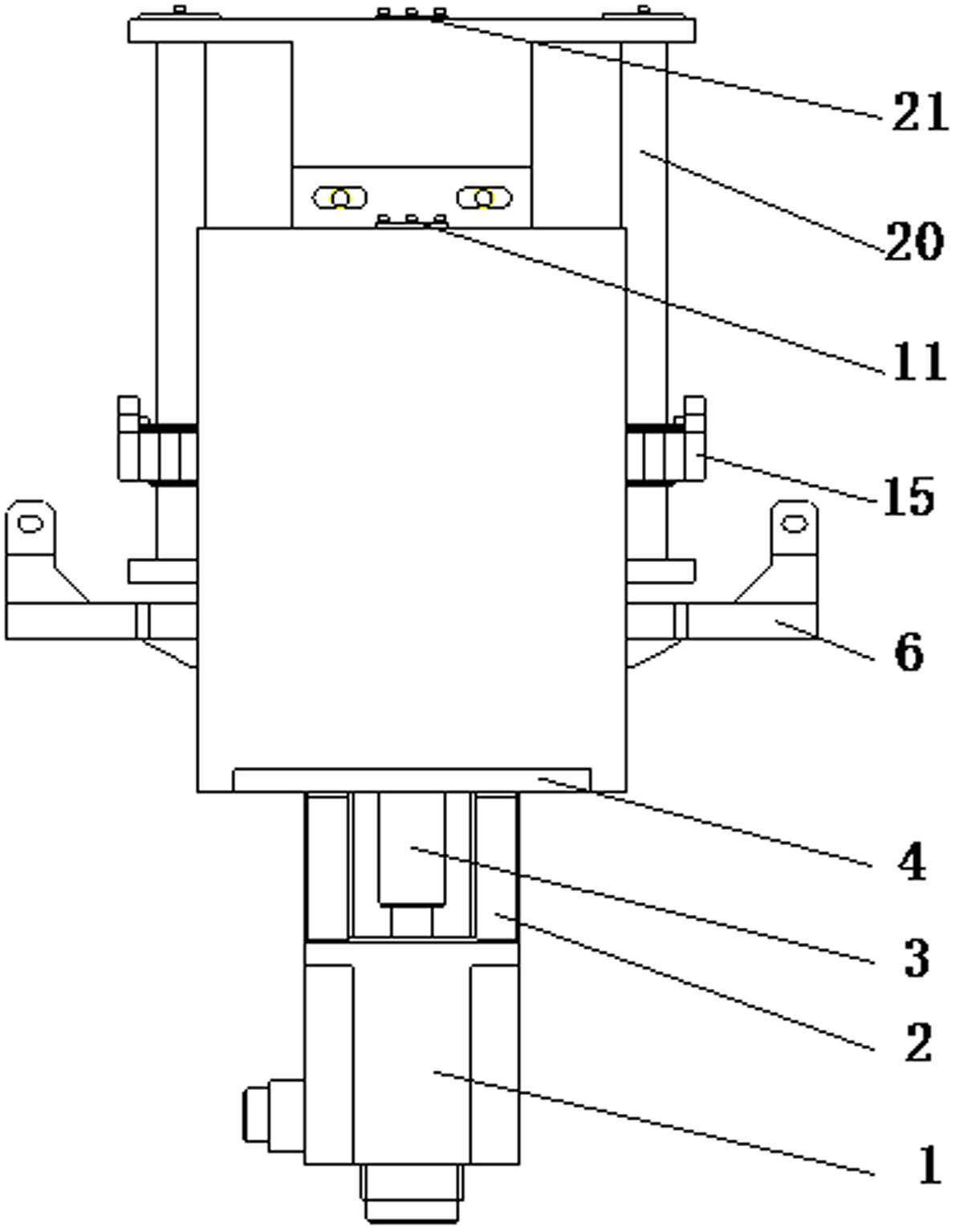

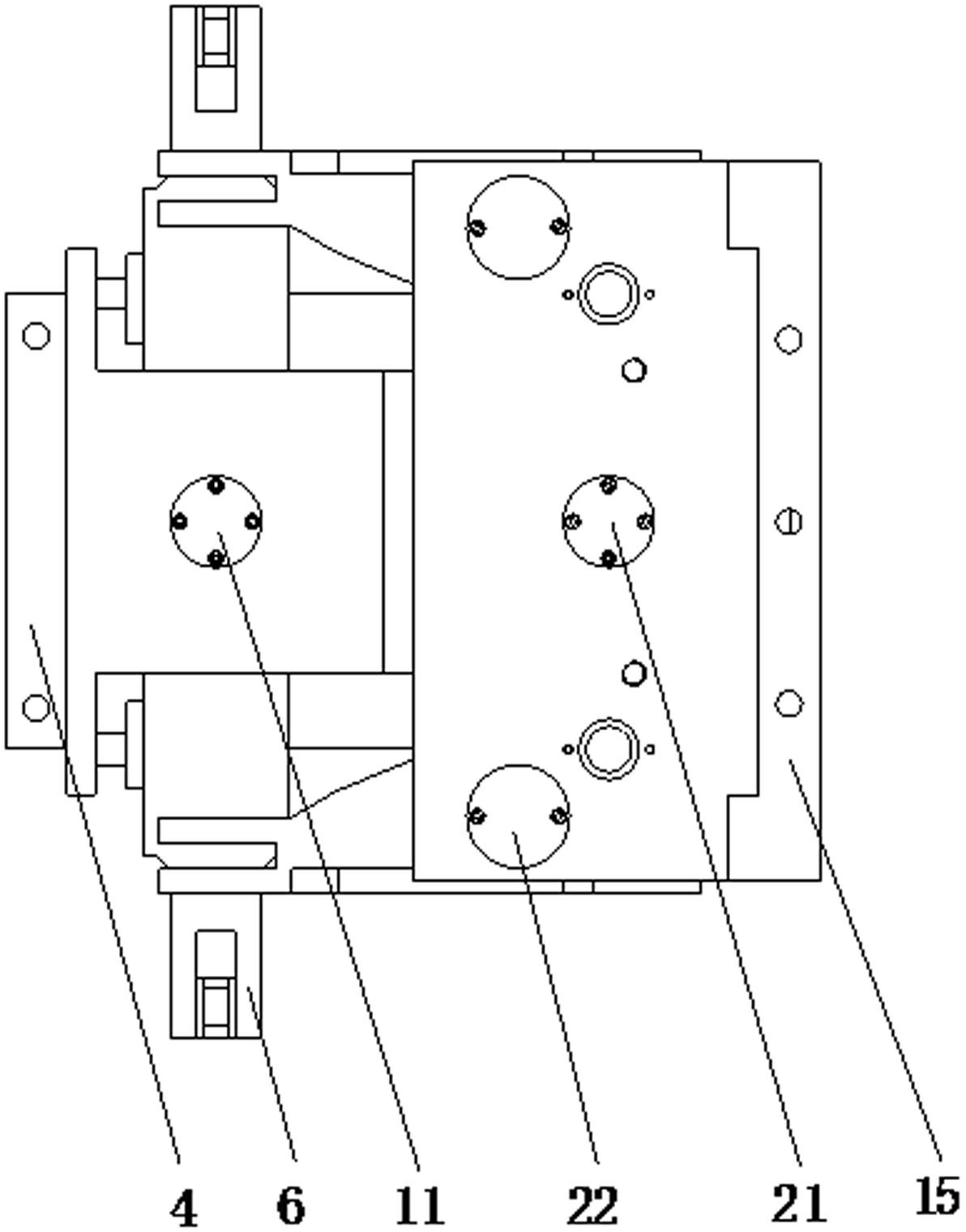

[0011] The structure of the servo drive device of the paper brick-shaped aseptic filling machine of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] see Figure 1 to Figure 5 , the structure of the paper brick-shaped aseptic filling machine servo drive device of the present invention includes an inner servo motor 12 and an outer servo motor 1, the outer servo motor 1 is fixed to the bottom of the outer servo motor seat 4 by four support columns 2 through screws, and the outer servo motor The intermediate output shaft of the motor 1 is connected to the ball screw 10 on the outer servo motor base 4 through a coupling 3, the lower bearing housing 5 of the ball screw 10 is fixed on the bottom of the outer servo motor base 4, and the ball screw nut 8 is connected to the outer leading The column fixing plate 6 is equipped with a ball screw 10, the upper bearing seat 11 of the ball screw 10 is fixed on the top of the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com