Radiant heat-conducting boiler

A technology for boilers and forehearths, applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of thermal energy utilization rate constraint assessment indicators, low thermal efficiency, etc., and achieve stable thermal flow field and NOX emission Low, even temperature distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

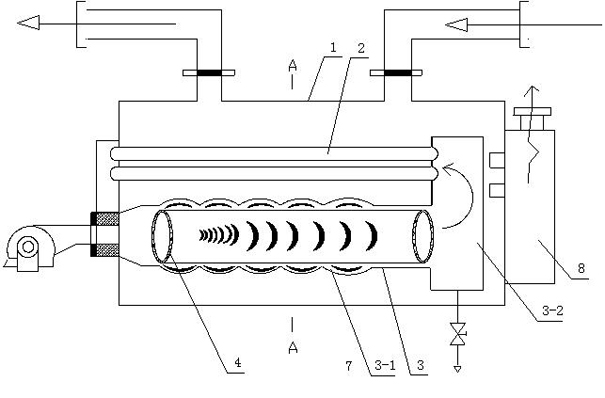

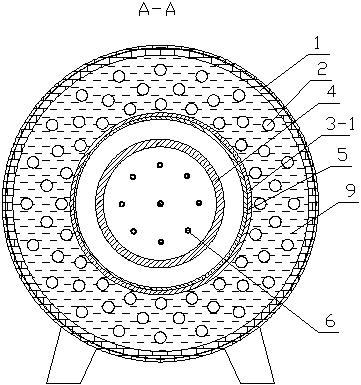

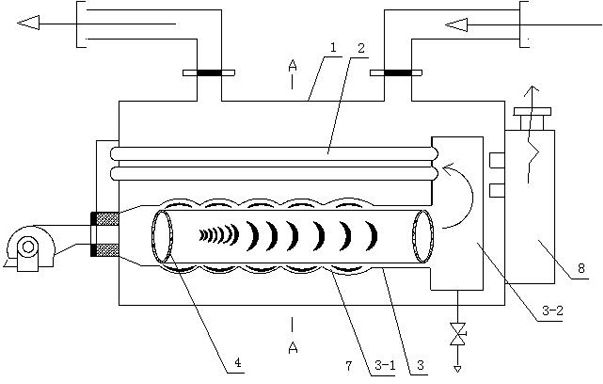

[0008] Such as figure 1 , 2 As shown, it is a radiation heat conduction boiler, which includes a shell 1, and a corrugated furnace 3 is arranged inside the shell 1. The corrugated furnace 3 includes a front furnace 3-1 and a rear furnace 3-2, and the diameter of the rear furnace 3-2 is Greater than the diameter of the fore furnace 3-1, the rear furnace 3-2 is connected to the rear end of the fore furnace 3-1. A number of fire tubes 2 are arranged between the fore furnace 3-1 and the shell 1, the front end of each fire tube 2 is fixedly connected with the shell 1 respectively, and the rear end of each fire tube 2 is respectively connected with the back furnace 3-2 And fixed connection. The outside of the fire tube 2 is filled with water 9, the inner surface of the forehearth 3-1 is provided with a high-magnesium composite aluminum silicate layer 5, the inner surface of the forehearth 3-1 is axially provided with an energy storage chamber 4, and the inside of the energy storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com