Electro-adsorption module modification system and process

An electro-adsorption and modification technology, applied in water/sludge/sewage treatment, dispersed particle separation, water/sewage multi-stage treatment, etc., can solve the problems affecting the desalination efficiency of the electro-adsorption module and achieve the effect of prolonging the life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

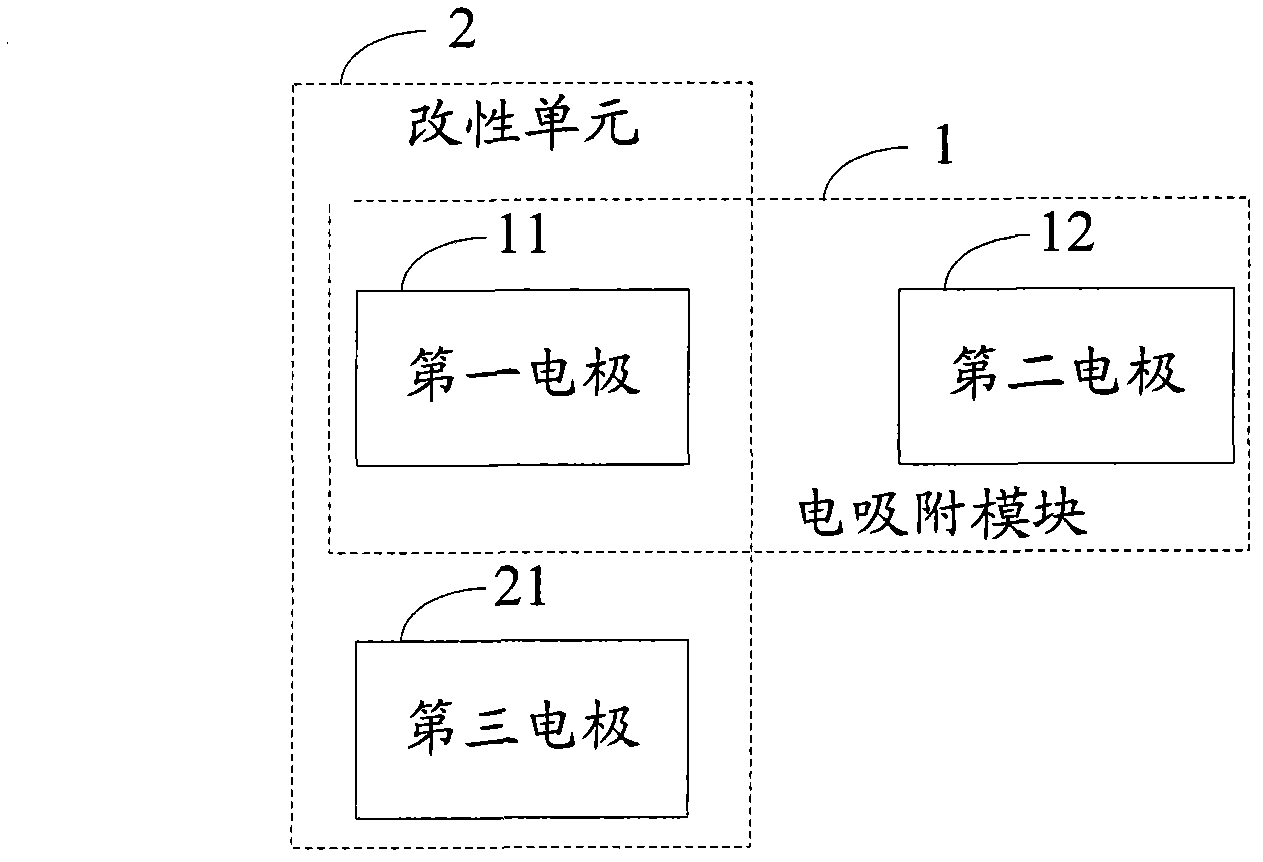

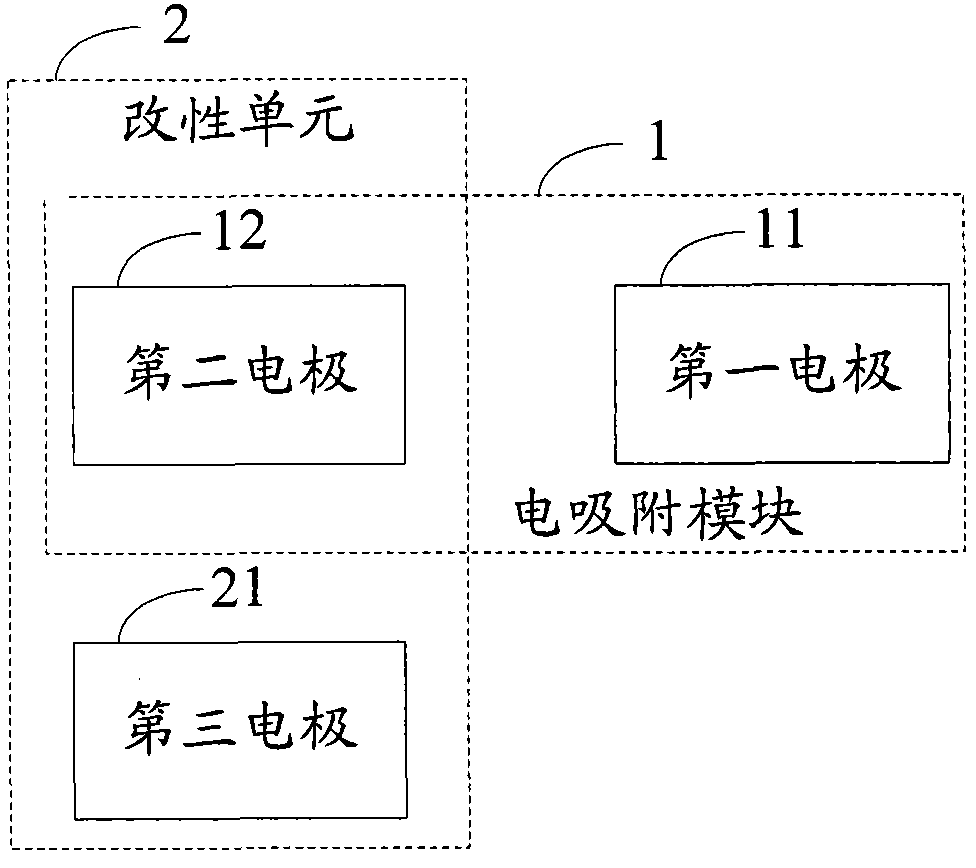

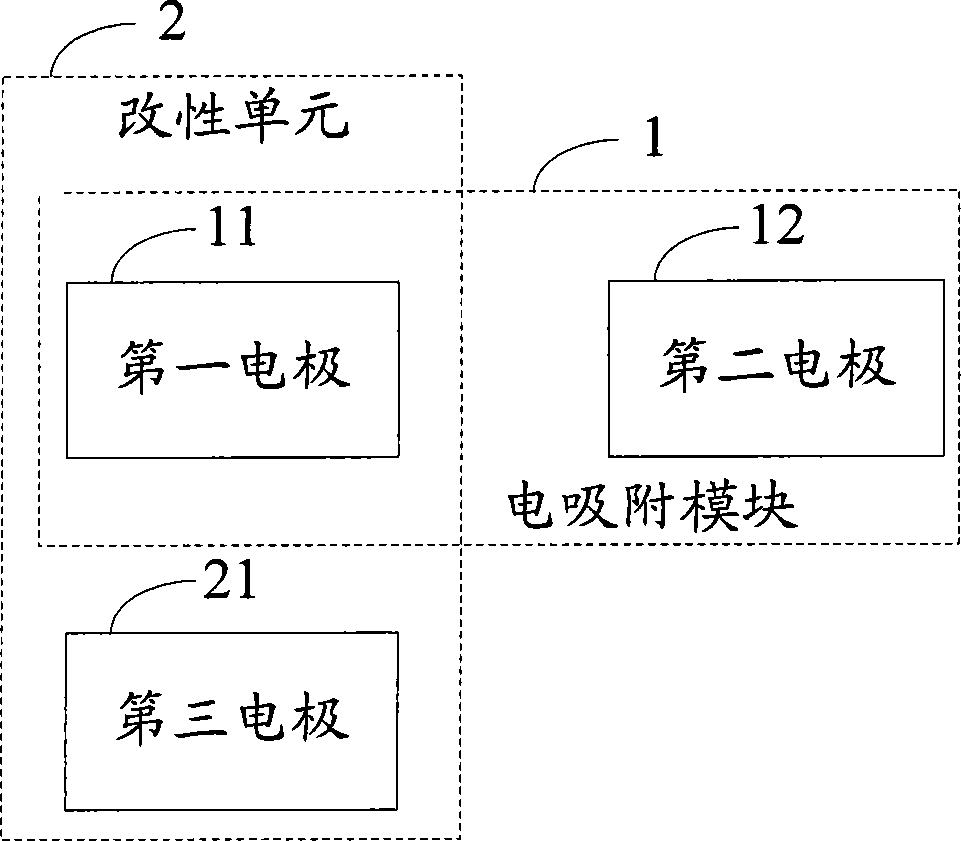

[0016] Embodiment 1. This embodiment provides an electro-adsorption module modification system. It is found through research that the functional groups generated due to oxidation can be eliminated by electrochemical reduction, thereby restoring the adsorption performance of the electrode material. Therefore, in this embodiment, the third electrode is introduced to electrochemically reduce the oxidized electrodes, and a stronger oxidation potential is applied to the third electrode, so that the electrode performance can be restored without destroying the electrodes used for adsorption in the module. see Picture 1-1 and Figure 1-2 shown, including:

[0017] The first electrode 11 and the second electrode 12 form the electrosorption module 1 when the electrosorption works.

[0018] The third electrode 21 does not participate in the normal adsorption process of the first electrode 11 and the second electrode 12, and only participates when the first electrode 11 and the second e...

Embodiment 2

[0020] Embodiment 2. This embodiment provides an electro-adsorption module modification process, which is implemented using the system described in Embodiment 1. In this embodiment, it is assumed that the first electrode is used as the electrosorption anode during the electrosorption process. Specifically, in the electrochemical modification process, the third electrode is used as a modified anode, and the first electrode is used as a modified cathode. The reduction potential applied between the third electrode and the first electrode is greater than the potential applied during the electrosorption of the electrosorption module, and then cathodically polarizes the first electrode as the modified cathode to complete the modification of the first electrode . The inventor considers that if the cathode has sufficient reduction potential, it will inevitably cause stronger damage to the third electrode as the anode, so a porous water-permeable inert electrode material can be used t...

Embodiment 3

[0021] Embodiment 3. This embodiment provides an electro-adsorption module modification process, which is implemented using the system described in Embodiment 1. In this embodiment, the electro-adsorption working process adopts the pole-reverse operation mode.

[0022] It has been found through research that the functional groups generated due to oxidation can be eliminated by electrochemical reduction, thereby restoring the adsorption performance of the electrode material. The basic unit of the electro-adsorption module is composed of positive and negative electrodes, and when the adsorption unit is formed, the potential is always positive, and the oxidation effect is much stronger than the reduction effect, that is, when the two electrodes are used as anodes, oxidation reactions will occur. However, when it is used as the cathode, there is not enough reduction potential to reduce it. If the cathode has sufficient reduction potential, it will inevitably cause stronger damage t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com