Method for cogeneration of methanol, CNG (compressed natural gas) and LNG (liquefied natural gas) from coke-oven gas and converter gas

A technology of converter gas and coke oven gas, which is applied in the field of methanol, CNG, and LNG preparation, can solve problems such as waste, achieve good process safety performance, and avoid the effect of pure oxygen conversion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

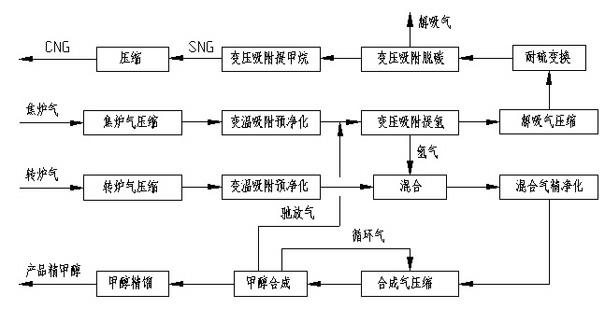

[0028] The joint production of coke oven gas and converter gas in this embodiment has an annual output of 100,000 tons of methanol and an annual output of 5668.161×10 4 N m 3 The CNG process is as follows:

[0029] Coke oven gas (dry basis) flow rate ~ 40000 Nm 3 / h, where H 2 : 55.65%, CH 4 : 25.67%, converter gas (dry basis) flow rate ~ 13000 Nm 3 / h, where CO: 60%, CO 2 : 16%.

[0030] Its process is as follows figure 1 shown.

[0031] Coke oven gas (wet basis) flow rate ~ 41700 Nm 3 / h, compressed to 2.1MPa by the coke oven gas compressor, enters the temperature swing adsorption pretreatment, the coke oven gas flow rate after pretreatment is ~40150 Nm 3 / h, synthetic exhaust gas flow ~ 6750 Nm 3 / h, the coke oven gas is mixed with the purge gas and enters the pressure swing adsorption hydrogen extraction process, and the proposed hydrogen flow rate is ~23200 Nm 3 / h, where H 2 : 98.0%, desorption gas flow ~ 23700 Nm 3 / h, where CH 4 : 43.3%, desorbed gas sen...

Embodiment 2

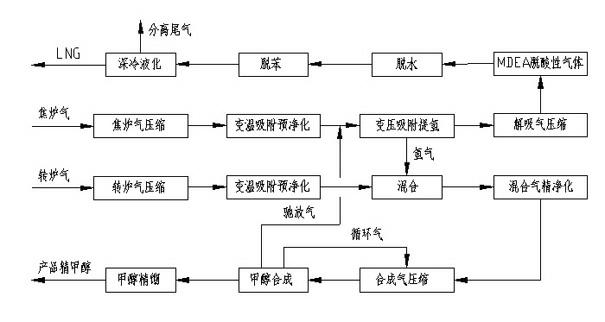

[0035] The joint production of coke oven gas and converter gas in this embodiment has an annual output of 100,000 tons of methanol and an annual output of 9010.176×10 4 N m 3 The LNG process is as follows:

[0036] Coke oven gas (dry basis) flow rate ~ 40000 Nm 3 / h, where H 2 : 55.65%, CH 4 : 25.67%, converter gas (dry basis) flow rate ~ 13000 Nm 3 / h, where CO: 60%, CO 2 : 16%.

[0037] Its process is as follows figure 2 shown.

[0038] Coke oven gas (wet basis) flow rate ~ 41700 Nm 3 / h, compressed to 2.1MPa by the coke oven gas compressor, enters the temperature swing adsorption pretreatment, the coke oven gas flow rate after pretreatment is ~40150 Nm 3 / h, synthetic exhaust gas flow ~ 6750 Nm 3 / h, the coke oven gas is mixed with the purge gas and enters the pressure swing adsorption hydrogen extraction process, and the proposed hydrogen flow rate is ~23200 Nm 3 / h, where H 2 : 98.0%, desorption gas flow ~ 23700 Nm 3 / h, where CH 4 : 43.3% sent to LNG proc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap