Concrete structure for supporting deep foundation pit

A concrete structure and deep foundation pit support technology, which is applied in the direction of foundation structure engineering, excavation, construction, etc., can solve the problems affecting the construction of earthworks, the extension of the construction period, and the extension of the construction period, so as to achieve the safety and reliability of the overall structure and reduce the construction cost. Effect of digging work, effect of increasing side resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

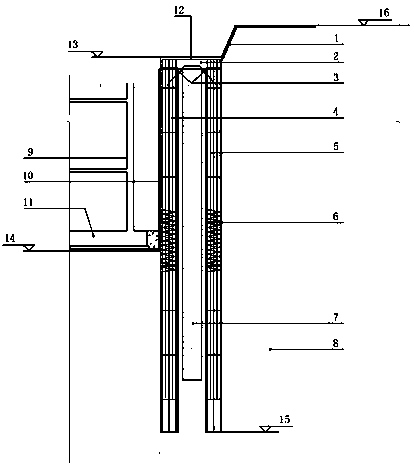

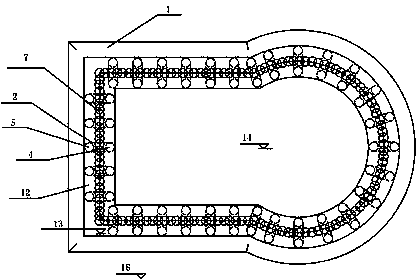

[0018] See figure 1 with figure 2 In this embodiment, a number of adjacent portal frames are connected by a circular reinforced concrete slab 12 at the top to form a space as a whole, so as to enhance the spatial lateral resistance of the structure. The portal frame consists of the front row of concrete cast-in-place piles 4 and the rear row of concrete cast-in-place piles 5 through the rigid connection of reinforced concrete corbels 2 and reinforced concrete haunched nodes 3, forming a portal frame with large in-plane lateral stiffness. At the same time, a three-axis mixing cement-soil pile 7 is provided in the portal frame. The three-axis mixing cement-soil pile 7 and the portal frame work together to further increase the lateral resistance of the structure.

[0019] In addition, a spiral stirrup densification area 6 is provided on the front row of concrete cast-in-place piles 4 and the rear row of concrete cast-in-place piles 5. The specific location of the spiral stirrup de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com