Multi-depth rotating-wheel closed sampler and method thereof

A sampler and multi-depth technology, applied in the direction of sampling devices, etc., can solve the problems of sampling operation and other problems, and achieve the effects of simple operation, small disturbance and low sampling cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

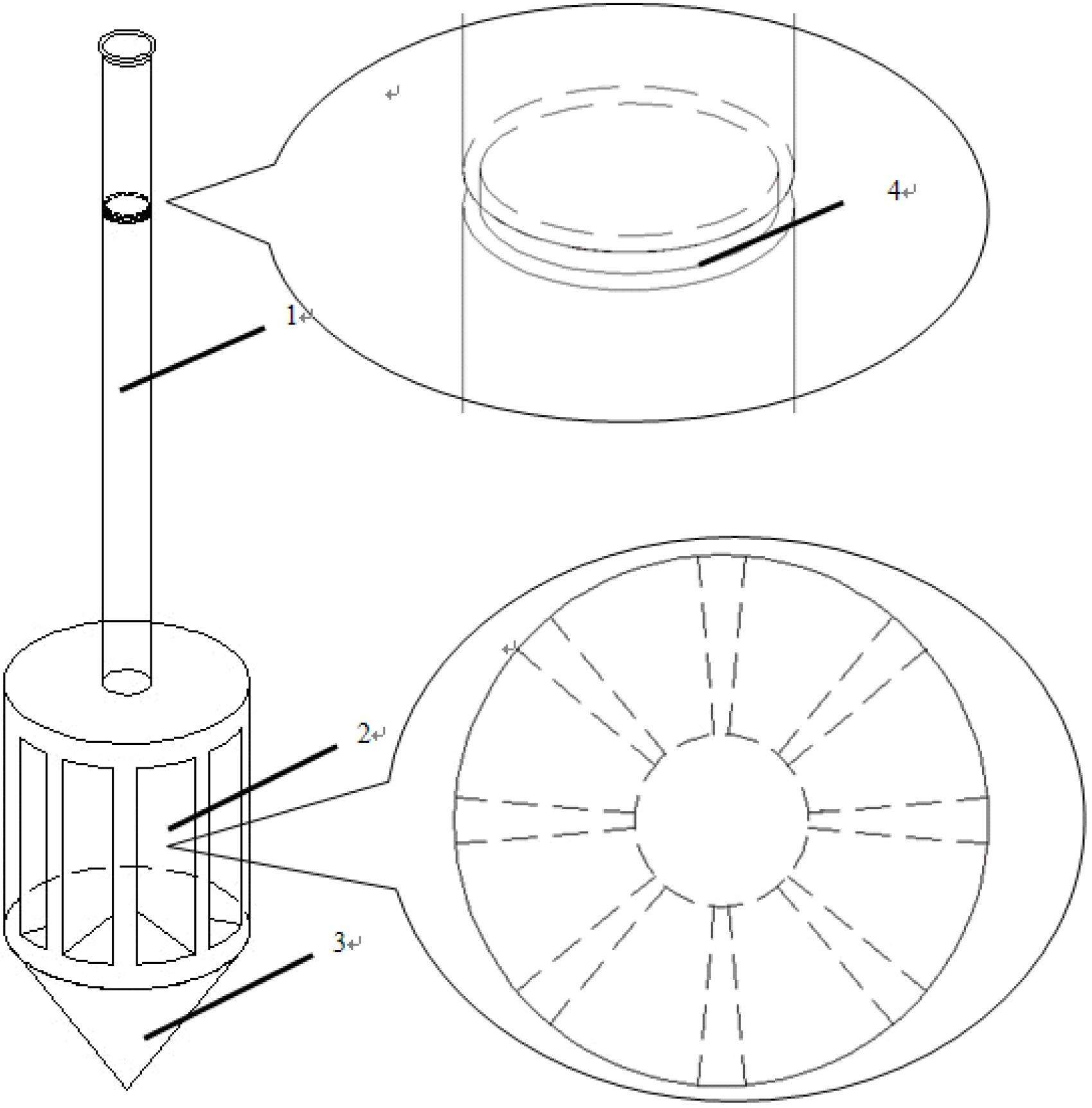

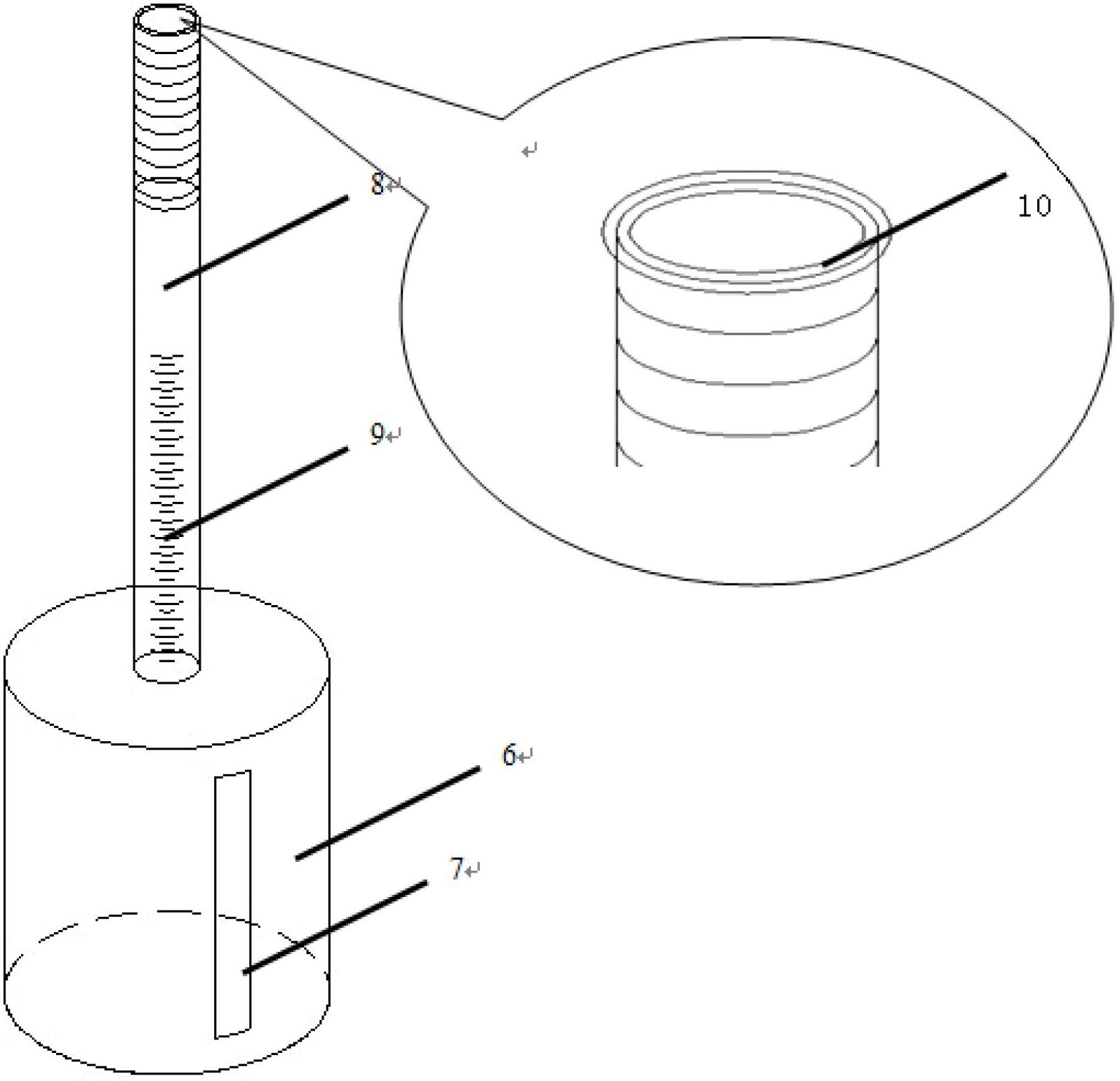

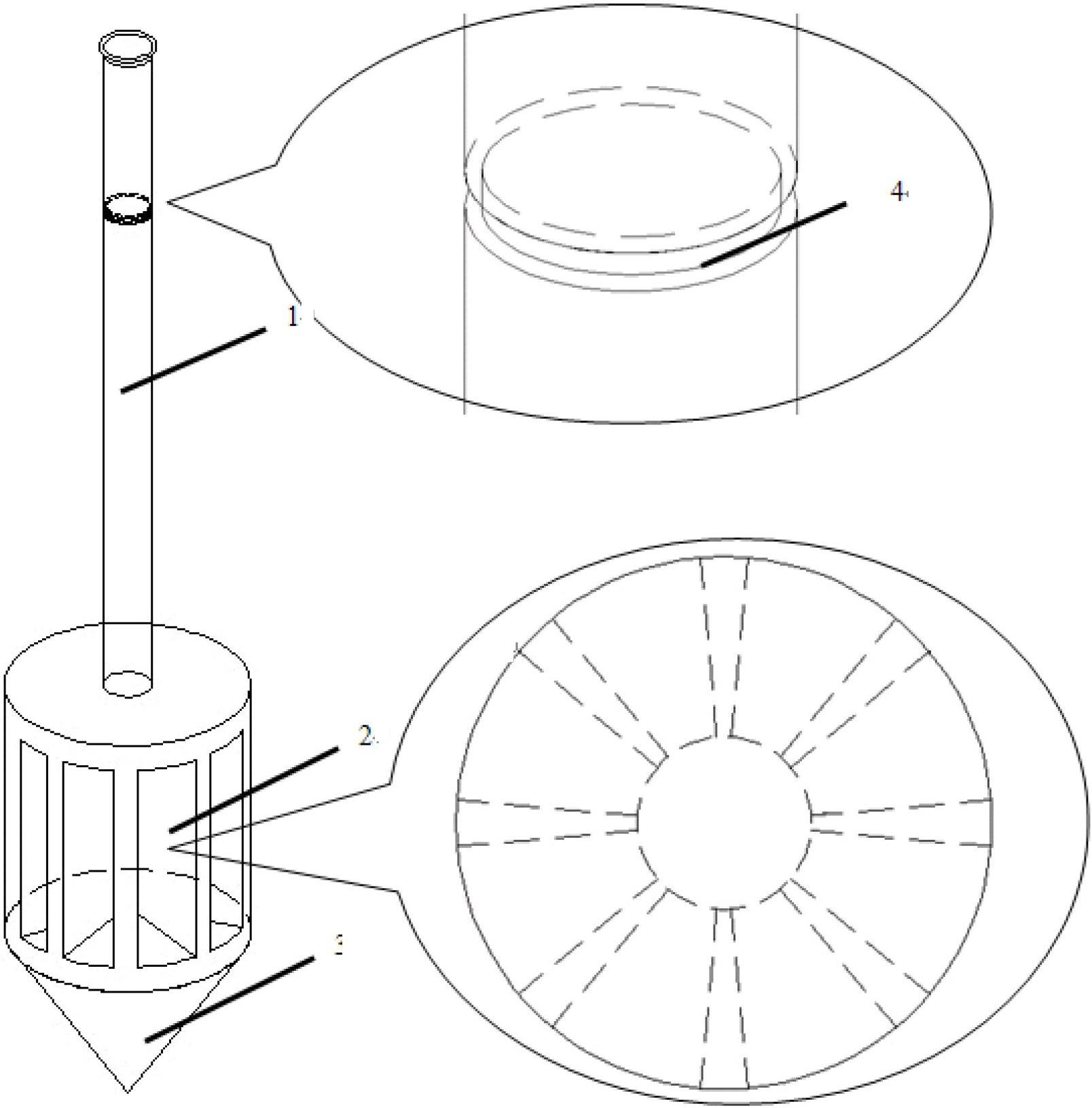

[0019] Such as figure 1 with figure 2 As shown, a rotary multi-depth closed sampler of the present invention includes a sampling handle 1 with a slot, a cylindrical sample storage nest 2, a sealing cylinder 6 and a rotating handle 8, and the middle part of the sampling handle 1 is provided with The annular card slot 4, the lower end of the sampling handle 1 is connected with the cylindrical sample storage nest 2, the cylindrical sample storage nest 2 is a structure in which the same size storage tanks are equidistant from the side of the cylindrical solid, and the adjacent sample storage tanks leave solid Interval, the lower end of the cylindrical sample storage nest 2 is connected to the conical drill head 3, the sealing cylinder 6 is a cylindrical thin-walled structure with one end face open and one end closed, the inner diameter of the sealing cylinder 6 is equal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com