High-speed intermittently-loaded circular block contact erosion tester

An ablation test and ring block technology, applied in the direction of testing wear resistance, can solve the problems of surface layer phase change, low speed, wear resistance effect, etc., to achieve the effect of real-time output and increase speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

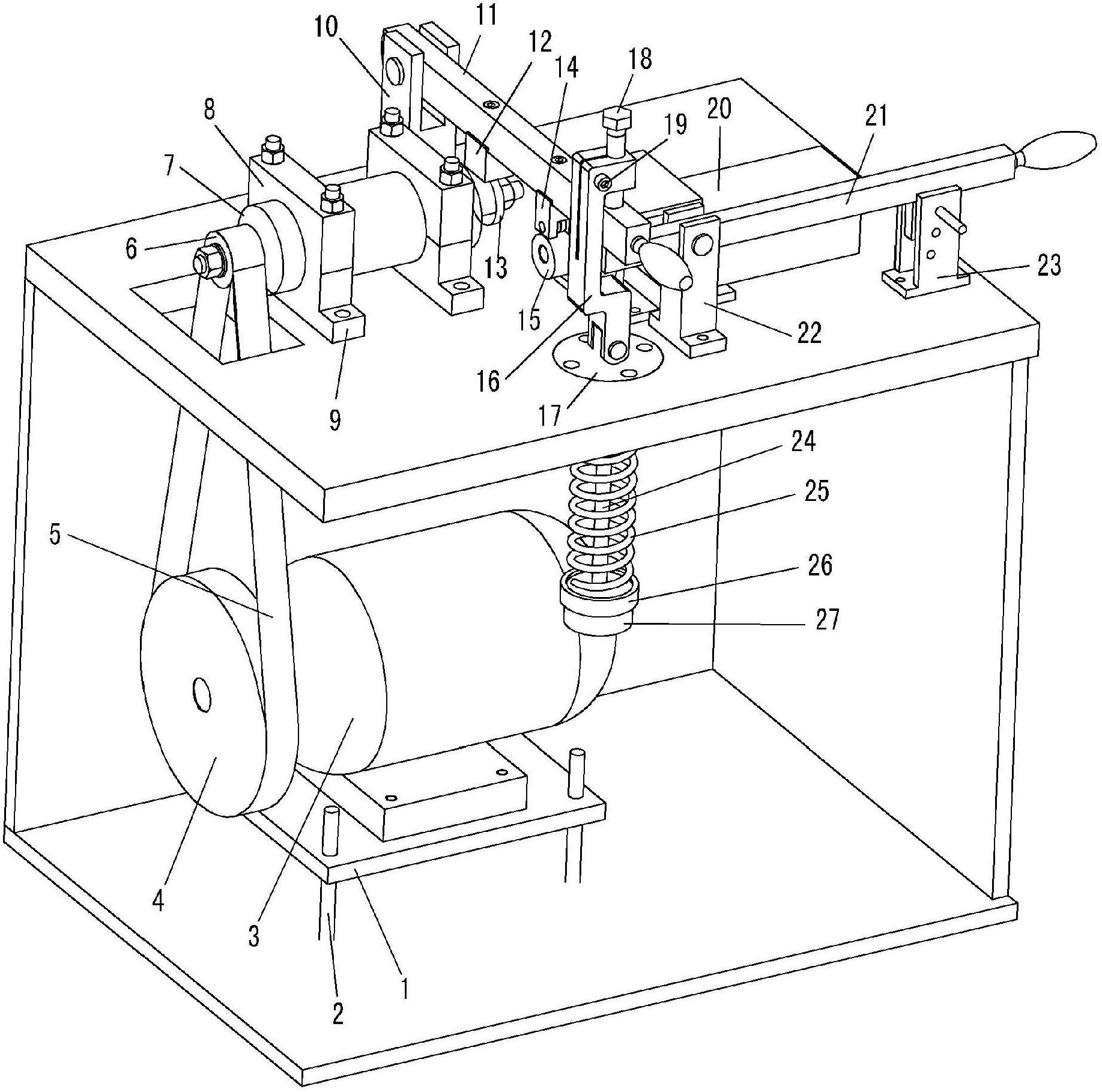

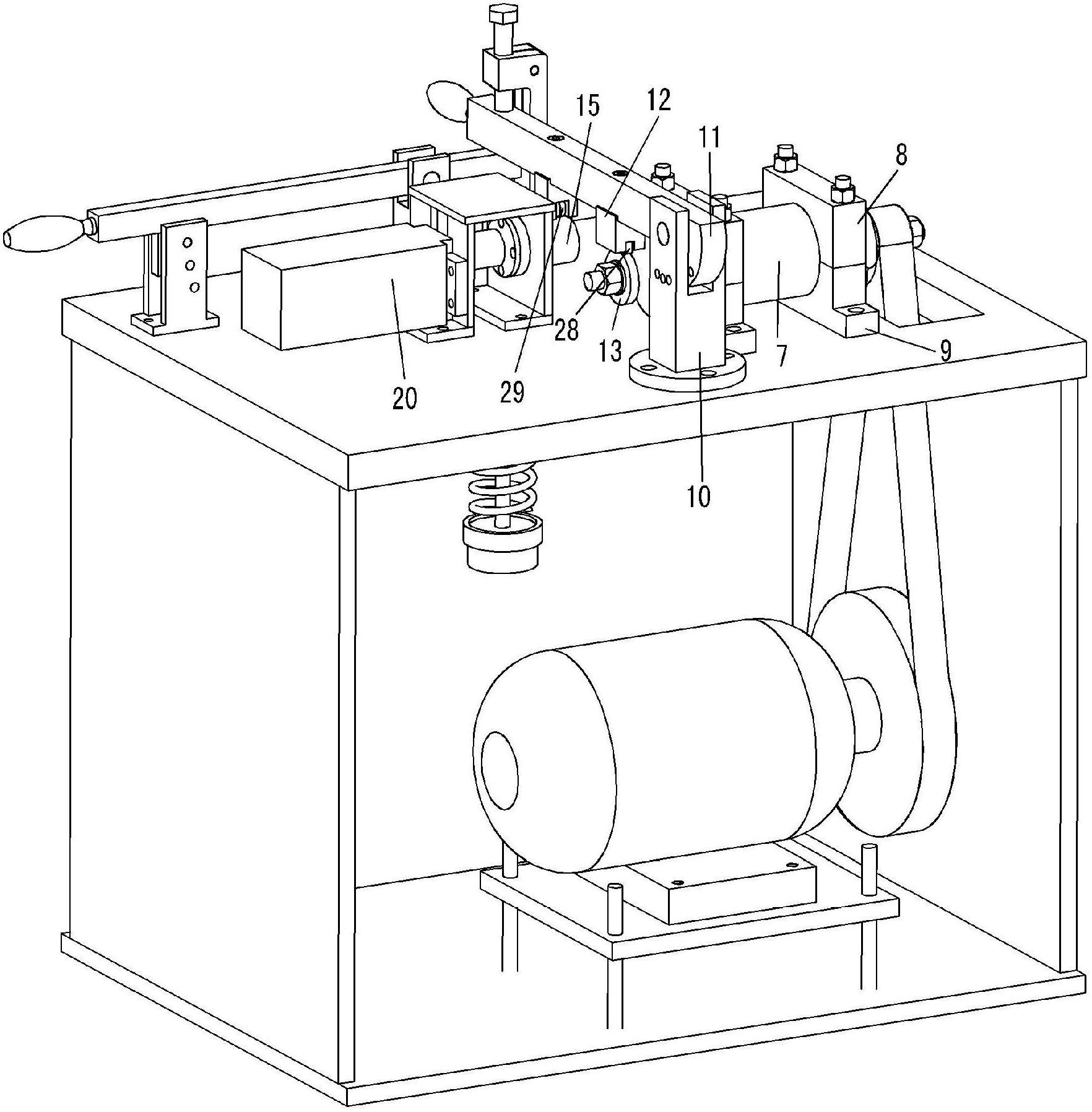

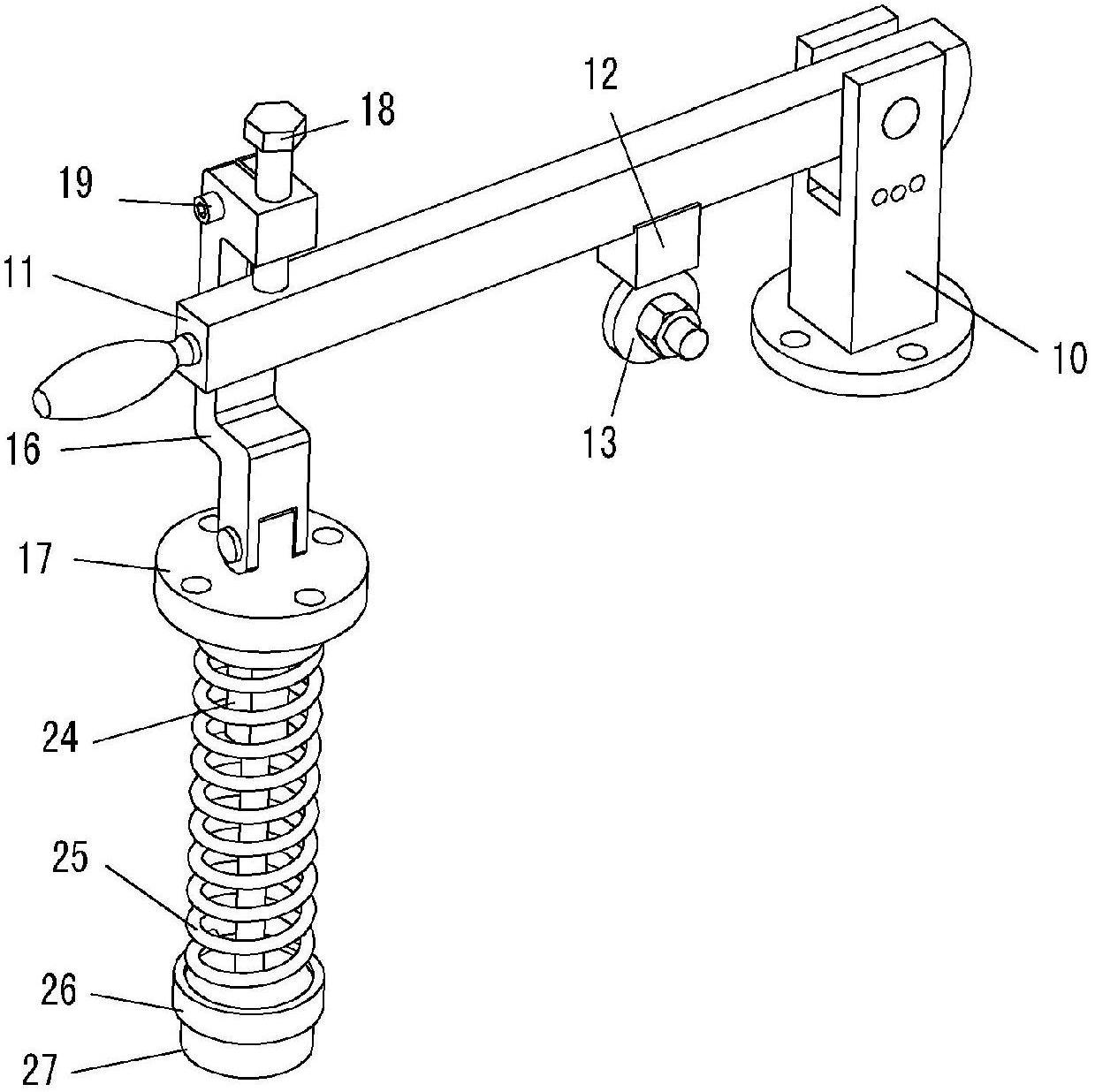

[0021] see figure 1 , figure 2 , image 3 The structural form of the high-speed, intermittently loaded ring block contact ablation testing machine in this embodiment is:

[0022] The mechanical main shaft 7 driven by the main motor 3 is arranged horizontally on the workbench, the test piece ring 13 is fixedly installed on the shaft end of the mechanical main shaft 7, the test piece block 28 is located directly above the test piece ring 13, and is mounted on the test piece ring 13 through the holder 12. On the loading rod 11 arranged horizontally, one end of the loading rod 11 is hinged on the loading support 10, and the other end is provided with a spring loading unit. Rod 16, loading bolt 18 is supported on the loading rod 11, and the loading bolt 18 is locked by the locking screw 19. The loading support rod 16 is hinged with the longitudinal loading guide rod 24 at the bottom, and the lower end of the longitudinal loading guide rod 24 is connected to the load measuring se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com