Method for detecting equipment equipotential bonding

A detection method and equipotential technology, applied in the direction of grounding resistance measurement, etc., can solve the problems of being unsuitable for chemical production site detection operations and high cost of testers, and achieve the effect of simple detection method, low detection cost, and electrical safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

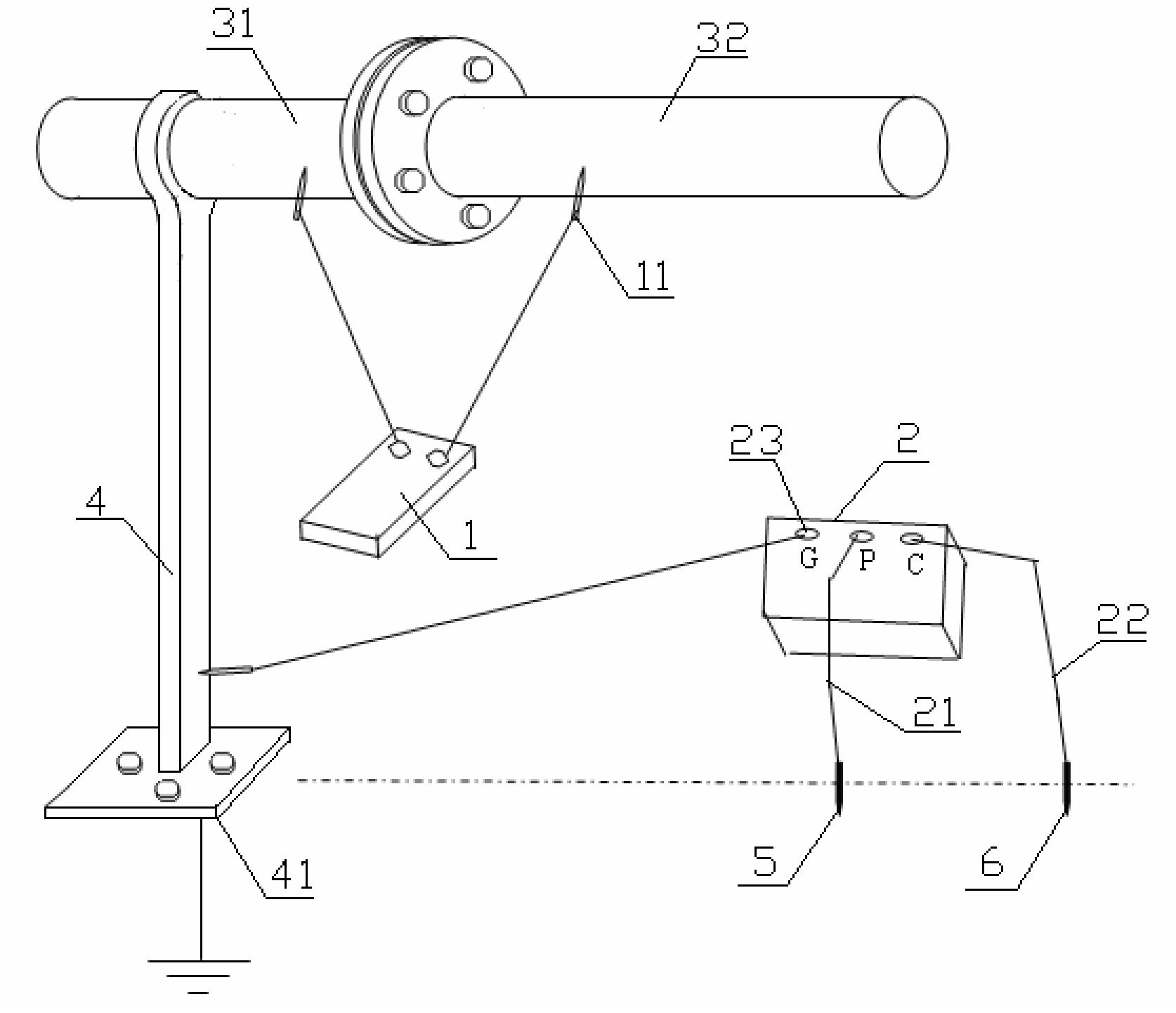

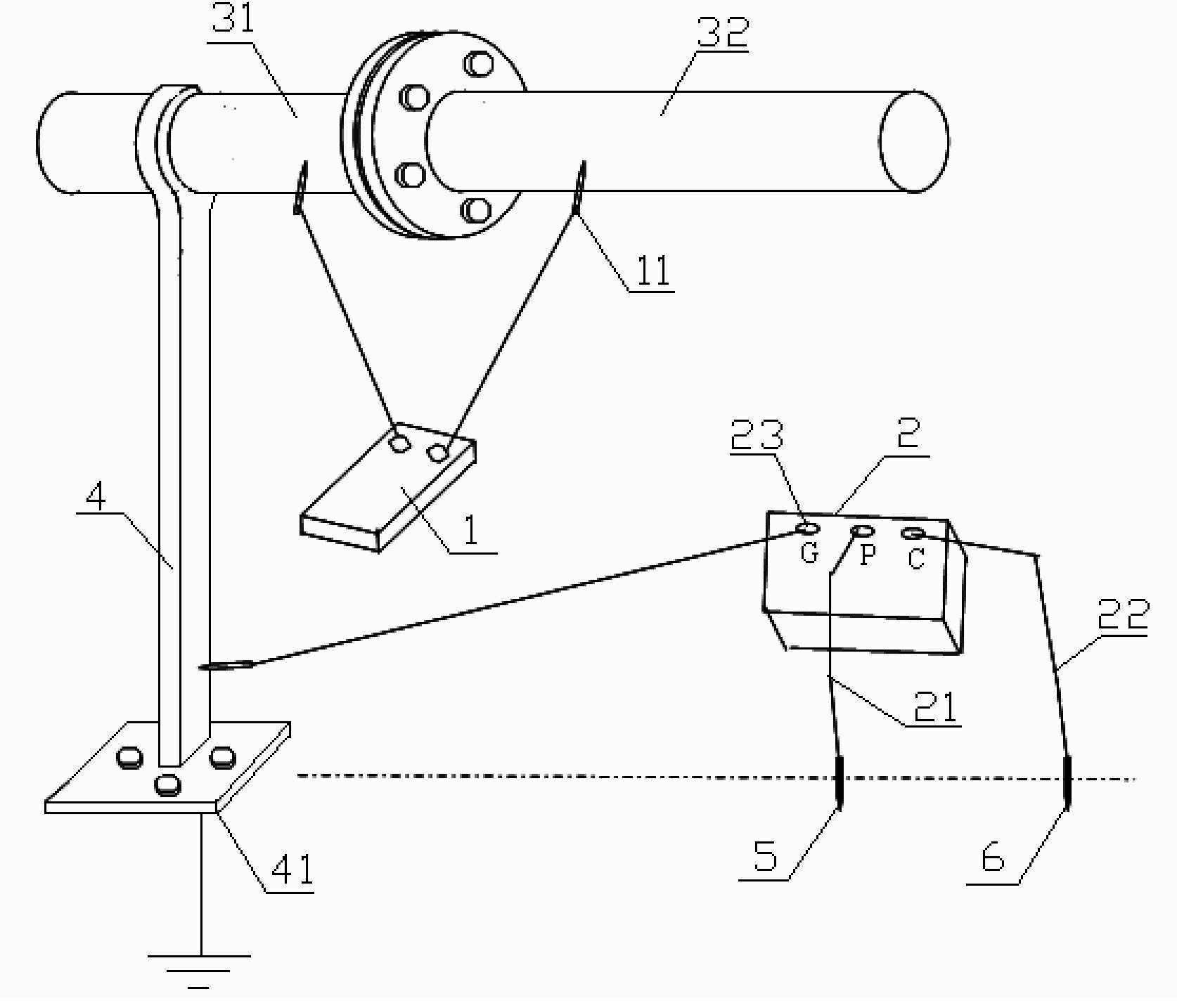

[0013] Such as figure 1 As shown, the detection method of equipment equipotential bonding of the present invention comprises milliohmmeter 1 and grounding resistance tester 2, and this method comprises the steps:

[0014] Step 1, using the milliohm meter 1 to detect the electrical resistance value between each metal coupling body 31 and 32, the measured electrical resistance value should be less than or equal to 0.03 ohms; each metal coupling body can be any method at the junction of various pipelines Between the blue plate, between the pipe and the support body, between various instruments and the pipe;

[0015] Step 2, the contact rod 11 of the milliohm meter 1 overlaps the metal coupling bodies 31 and 32 for more than 2 seconds, and the detection operation is carried out in a ventilated environment;

[0016] Step 3, using the ground resistance tester 2 to detect the ground resistance value of each grounded metal coupling body 4, and the measured ground resistance value is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com