Edible fungus compost, production method thereof and edible fungus culture process

A production process and edible fungus technology, applied in the field of edible fungus cultivation material and its production process, can solve the problems of unfavorable sustainable development of edible fungi industry, slow decomposition of cellulose and lignin, deterioration of edible fungi reproduction environment, etc., and achieve good promotion Application potential, high biotransformation rate, and improved economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

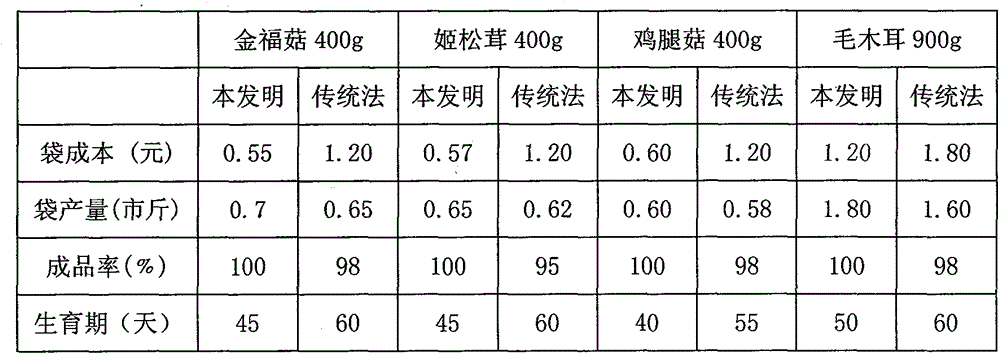

Image

Examples

Embodiment 1

[0052] An edible fungus cultivation material, which contains 80 parts of fungus chaff, 5 parts of cottonseed hulls, 5 parts of bran, 3 parts of corn flour, 1.2 parts of gypsum powder, 4 parts of quicklime, 1.5 parts of superphosphate, and 0.3 parts of strongin share.

Embodiment 2

[0054] A cultivation material for edible fungi, which contains 75 parts of fungus chaff, 10 parts of cottonseed husks, 8 parts of bran, 3.5 parts of corn flour, 1.3 parts of gypsum powder, 1 part of quicklime, 0.8 parts of superphosphate, and 0.4 parts of strongin share.

Embodiment 3

[0056] A cultivation material for edible fungi, which contains 70 parts of fungus chaff, 15 parts of cottonseed hulls, 7 parts of bran, 3 parts of corn flour, 1 part of gypsum powder, 3 parts of quicklime, 0.5 parts of superphosphate, and 0.5 parts of share.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com