A vertical magnetic separator

A magnetic separator, vertical technology, applied in magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of low content of iron particles and high cost, improve the separation rate, low production cost, and save drying procedures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

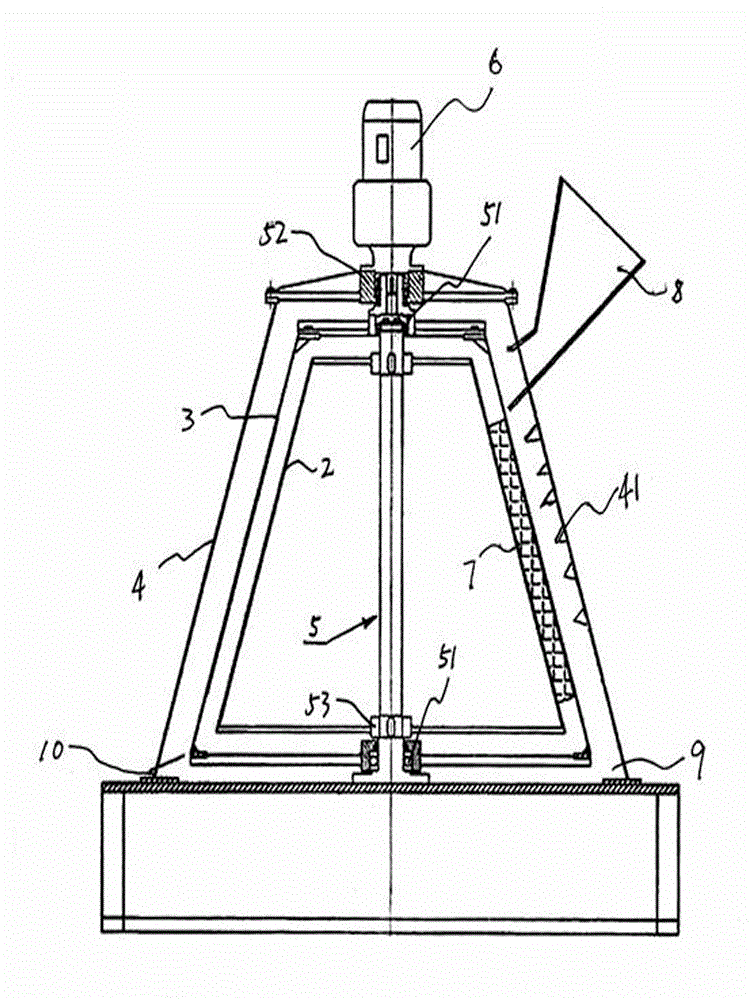

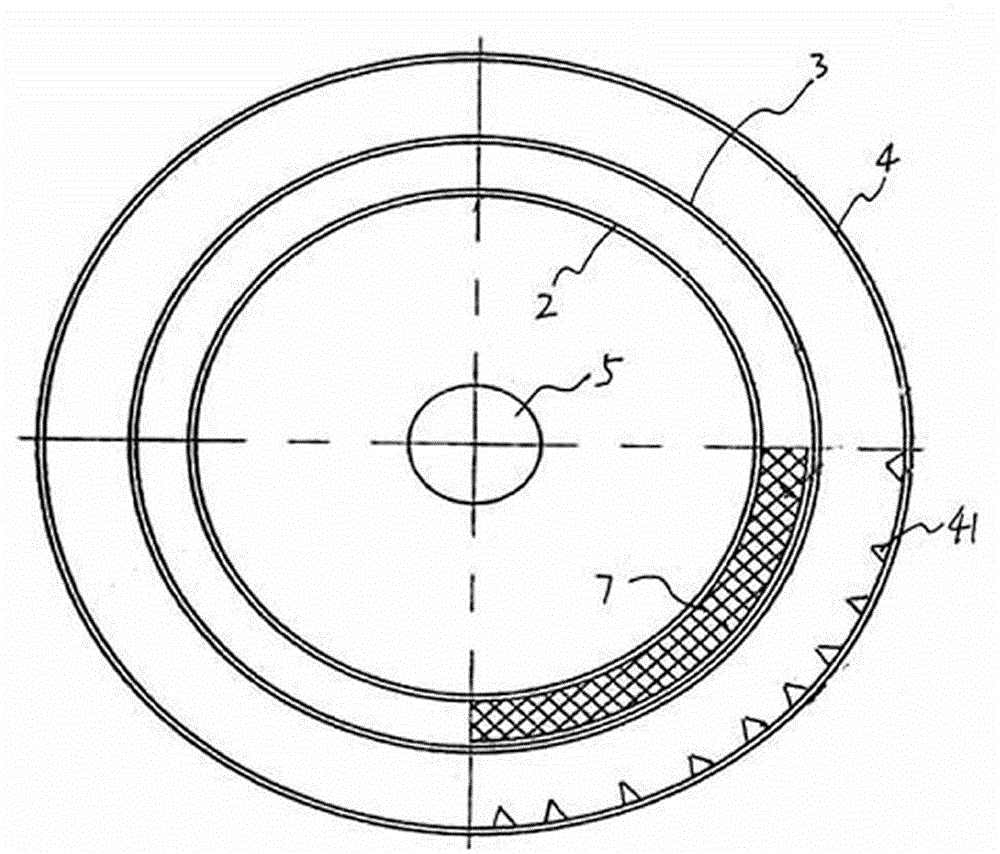

[0014] see figure 1 and figure 2 , these two accompanying drawings show a schematic view of the appearance structure of an embodiment of the vertical magnetic separator proposed by the present invention. The magnetic separator includes a truncated-conical inner cylinder 2 , a truncated-conical outer cylinder 4 and a truncated-conical rotating cylinder 3 installed on a frame 1 .

[0015] A vertical shaft 5 is installed on the frame 1, and the upper and lower ends of the vertical shaft 5 pass through the central parts of the upper and lower bottom surfaces of the frustum-shaped inner cylinder 2, the frustum-shaped rotating cylinder 3 and the frustum-shaped outer cylinder 4 respectively. The frustum-shaped inner cylinder 2 and the truncated-cone-shaped outer cylinder 4 are respectively defined on the vertical axis 5 by the upper and lower shaft sleeves, while the truncated-conical rotating cylinder 3 is defined on the vertical axis 5 by the bearing 51 and the bearing slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com